Alginate-based composite photo-catalytic aerogel material and preparation method thereof

A technology of gel materials and catalytic materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the obstacles to industrialization, powder photocatalyst limitations, Can not be reused and other problems, to achieve the effect of low cost, good adsorption performance and high visible light catalytic performance, and improve the ability of UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

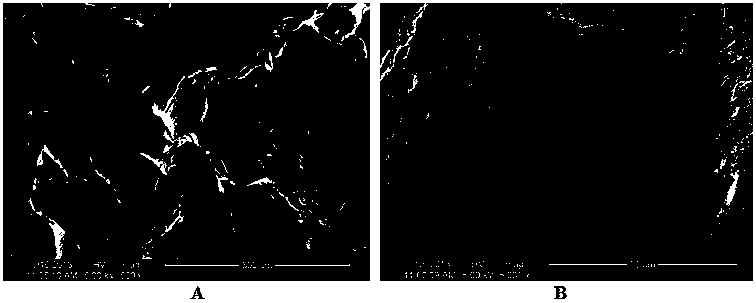

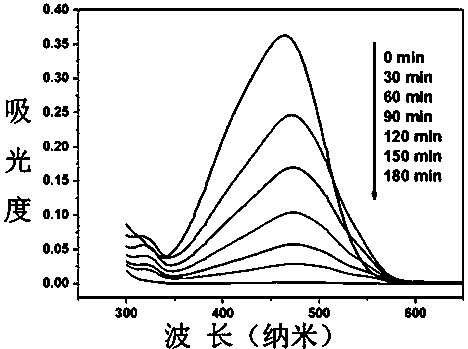

[0026] a) Weigh 0.1g commercial TiO 2 Nano-powder P25 was added to 100mL deionized water, mechanically stirred and ultrasonically dispersed for 1h to prepare nano-TiO with a concentration of 1g / L 2 Dispersions;

[0027] b) Under vigorous stirring, add 0.1 g sodium alginate to the above nano-TiO 2 In the dispersion liquid, stir vigorously to dissolve it completely. At this time, the concentration of sodium alginate in the solution is 1g / L, and then continue to stir for 1h;

[0028] c) Ultrasonic defoaming and vacuum pumping are performed on the above mixed solution. The ultrasonic time is 30 minutes, and the pumping time is 30 minutes, so as to discharge the gas dissolved in the mixed solution;

[0029] d) Pour the exhausted mixed solution into a petri dish with a diameter of 90mm for freeze-drying, cooling rate: 1°C / min, freezing temperature: -30°C, freezing time: 2h, then at -5°C, vacuum Dry under the condition of 200 Pa for 24h to obtain bulk material;

[0030] e) Put th...

Embodiment 2

[0035] a) Weigh 2g of bismuth nitrate hydrate and add it to 10ml of hydrochloric acid, stir at room temperature for 30min, then adjust the pH=4~7 with ammonia water, continue to stir at room temperature for 30min, centrifuge, wash, and finally dry at 110°C for 12h to obtain a white BiOCl powder; Take 0.2 g of the obtained BiOCl white powder, add it to 100 mL of deionized water, mechanically stir and ultrasonically disperse for 2 hours, and prepare a nano-BiOCl dispersion with a concentration of 2 g / L;

[0036] b) Under vigorous stirring, add 0.3 g of sodium alginate into the above-mentioned nano-BiOCl dispersion liquid, and stir vigorously to dissolve it completely. At this time, the concentration of sodium alginate in the solution is 3 g / L, and then continue to stir for 1 h;

[0037] c) Ultrasonic defoaming and vacuum pumping are performed on the above mixed solution. The ultrasonic time is 30 minutes, and the pumping time is 30 minutes, so as to discharge the gas dissolved in...

Embodiment 3

[0042] a) Weigh 1.5mmol zinc chloride and add it to 75ml water, stir until dissolved, then add 1mmolInCl under stirring condition 3 4H 2 O, add 3mmol thioacetamide, stir for 30min, then transfer to a 100ml lined polytetrafluoroethylene autoclave, keep at 160°C for 12h, cool to room temperature, centrifuge, wash, and finally dry at 60°C for 12h to obtain Zn 3 In 2 S 6 Yellow powder; weigh the resulting Zn 3 In 2 S 6 Add 0.5g of powder into 100mL of deionized water, mechanically stir and ultrasonically disperse for 4 hours to obtain a concentration of 5g / L nano Zn 3 In 2 S 6 Dispersions;

[0043] b) Under vigorous stirring, add 0.5 g propylene glycol alginate to the above nano Zn 3 In 2 S 6 In the dispersion liquid, stir vigorously to make it dissolve completely. At this time, the concentration of propylene glycol alginate in the solution is 5g / L, and then continue to stir for 1 hour;

[0044] c) Ultrasonic defoaming and vacuum pumping are performed on the above mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com