Single-ion polymer electrolyte, and preparation method and application thereof

A polymer and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of lithium ion concentration, mechanical properties, high ion conductivity, etc., to achieve simple synthesis, Good thermal stability and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

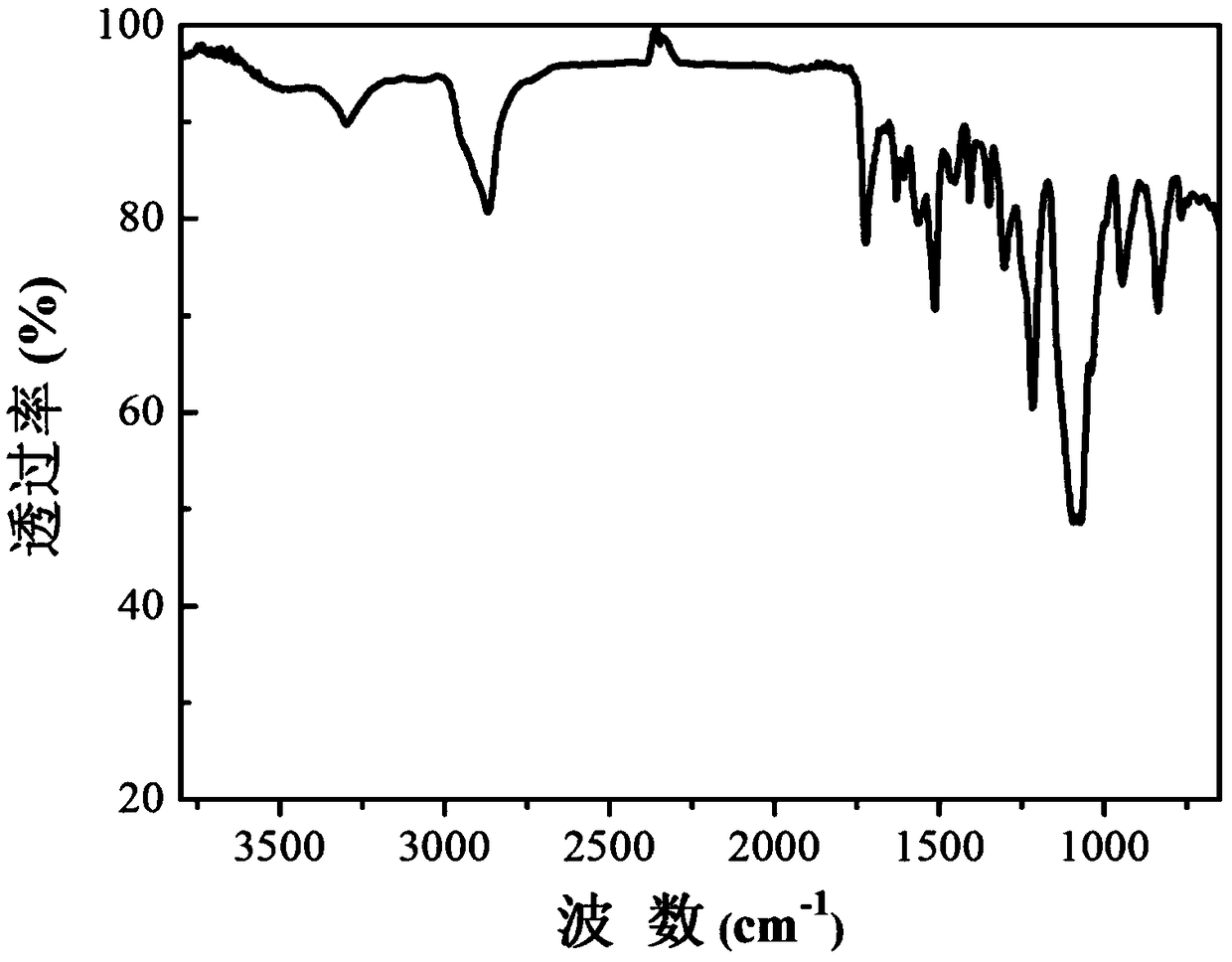

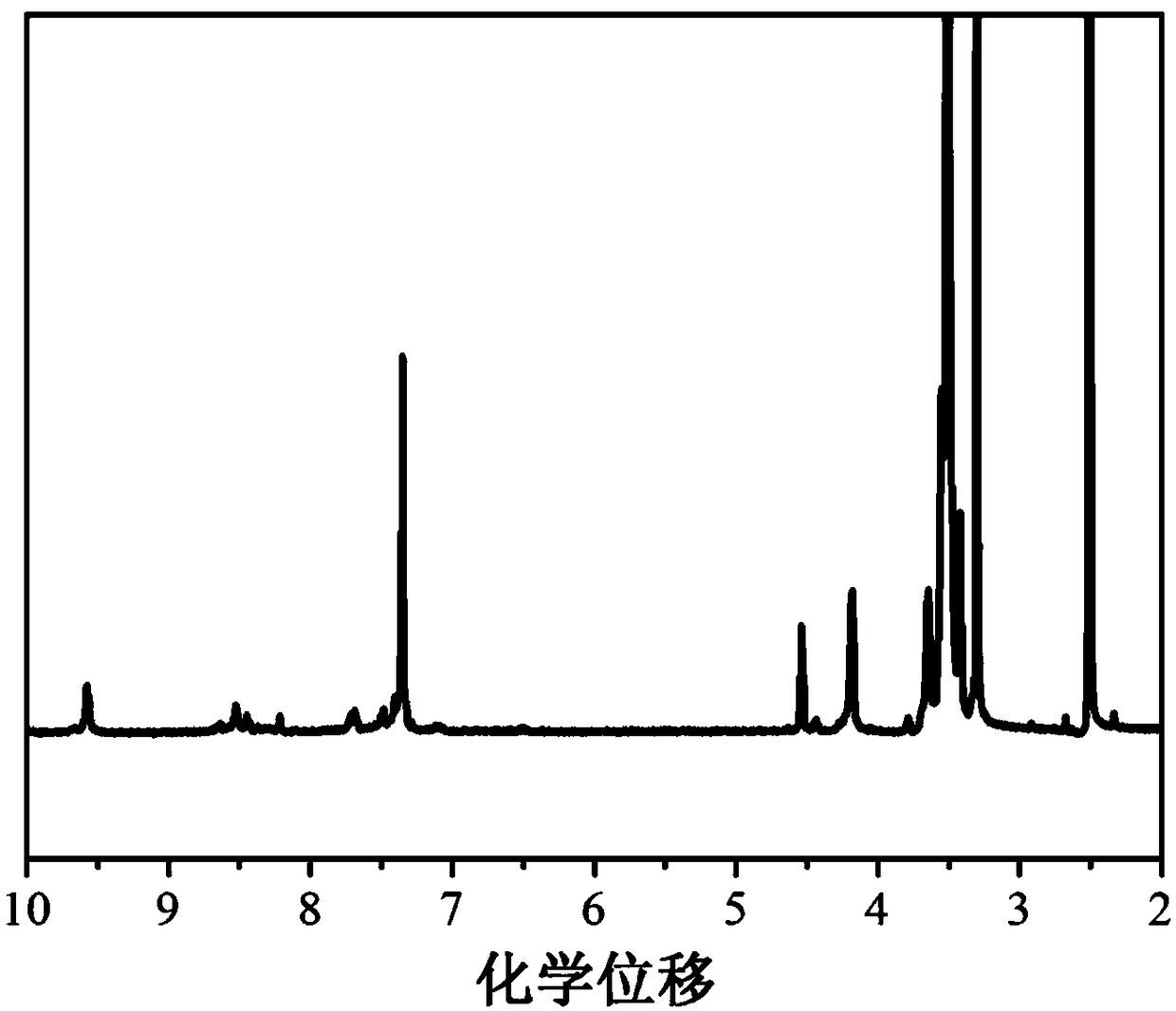

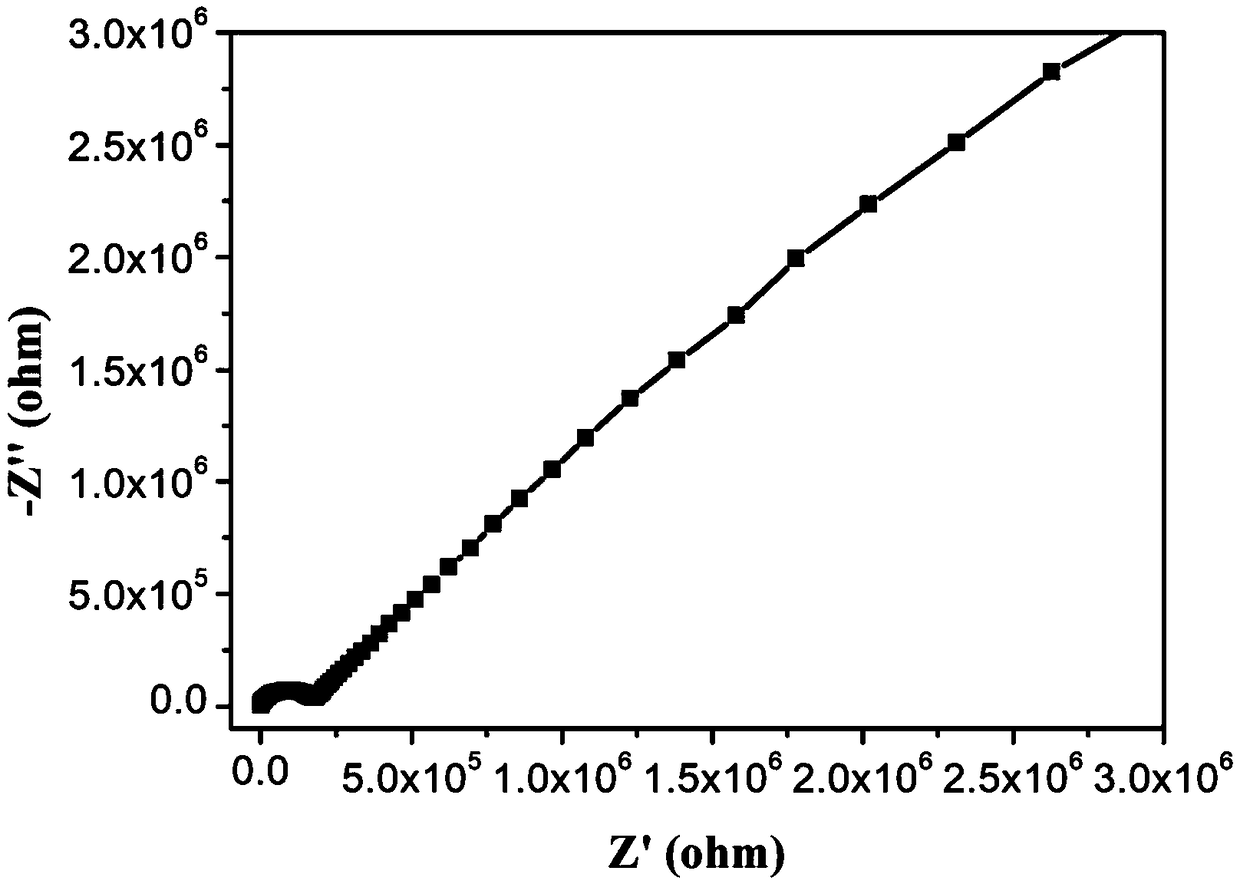

[0023] Embodiment 1: The preparation method of the single-ion polymer electrolyte in this embodiment is implemented according to the following steps:

[0024] 1. Under the protection of an inert gas atmosphere, add lithium dicarboxybenzenesulfonate and polyethylene oxide into the solvent at a molar ratio of 1:2.0~2.1, conduct condensation reaction at a temperature of 120~140°C, wash with water, and dry Afterwards, the reaction product is obtained;

[0025] 2. Add the reaction product obtained in step 1 and p-phenylene diisocyanate or 4,4'-methylene bis(phenylisocyanate) into the solvent at a molar ratio of 1:1, and at a temperature of 90-120°C The polycondensation reaction is carried out under the following conditions to obtain a polymer product, and the polymer product is purged, washed with water, and dried after dialysis to obtain a polymer electrolyte;

[0026] 3. Dissolving the polymer electrolyte obtained in step 2 in N,N-dimethylformamide, casting and drying to form a ...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that the inert gas described in step 1 is nitrogen or argon.

specific Embodiment approach 3

[0031] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the solvent described in step 1 and step 2 is N,N-dimethylformamide (DMF), N,N-dimethylformamide amide (DMAc) or N-methylpyrrolidone (NMP).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com