Preparation method and application of nanometer magnesium oxide composite material

A technology of nano-magnesia and composite materials, which is applied in the field of preparation of nano-magnesia composite materials, which can solve the problems of poor selectivity, large floor space, and large energy consumption, and achieve simple and easy-to-control steps, low environmental risks, and high adsorption efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take a water-soluble resin with a mass ratio of 5% and dissolve it in 30% water, then add 20% corn stalks, 20% nano-magnesium oxide, 20% kaolin and 5% gelatin in turn, mix well, and dry it at 300°C Calcined for 2 hours, composite material 1 was obtained.

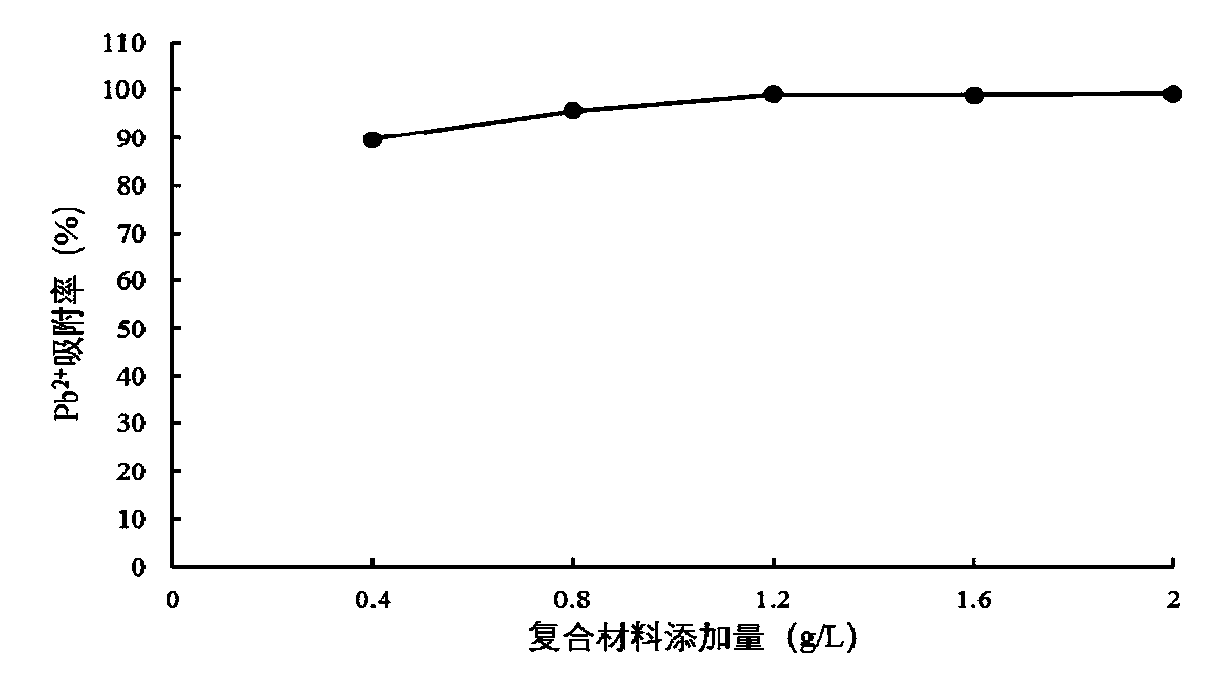

[0030] Weigh a certain amount of composite material 1 respectively and place in the conical flask, add 100mg / L of Pb 2+ Solution, so that the addition amount of composite material 1 is 0.4g / L, 0.8g / L, 1.2g / L, 1.6g / L and 2.0g / L respectively, placed on a magnetic stirrer to stir and absorb, and the speed is 250r / min , after 30 minutes of adsorption, filtered through a 0.45 μm filter membrane, each treatment was repeated 3 times, and the Pb in the solution before and after adsorption was determined by atomic absorption spectrophotometry 2+ concentration.

[0031] The result shows as figure 1 , when the addition of composite material 1 is 0.4g / L, Pb 2+ The adsorption rate is about 90%, after adding 0.8g / L, Pb 2+ The ...

Embodiment 2

[0033] Take 5% water-soluble resin by mass and dissolve it in 30% water, then add 30% nano-magnesia, 20% kaolin, 10% corn stalks, and 5% gelatin in sequence, mix well, and after drying, 400 Calcined at ℃ for 1 h to obtain composite material 2.

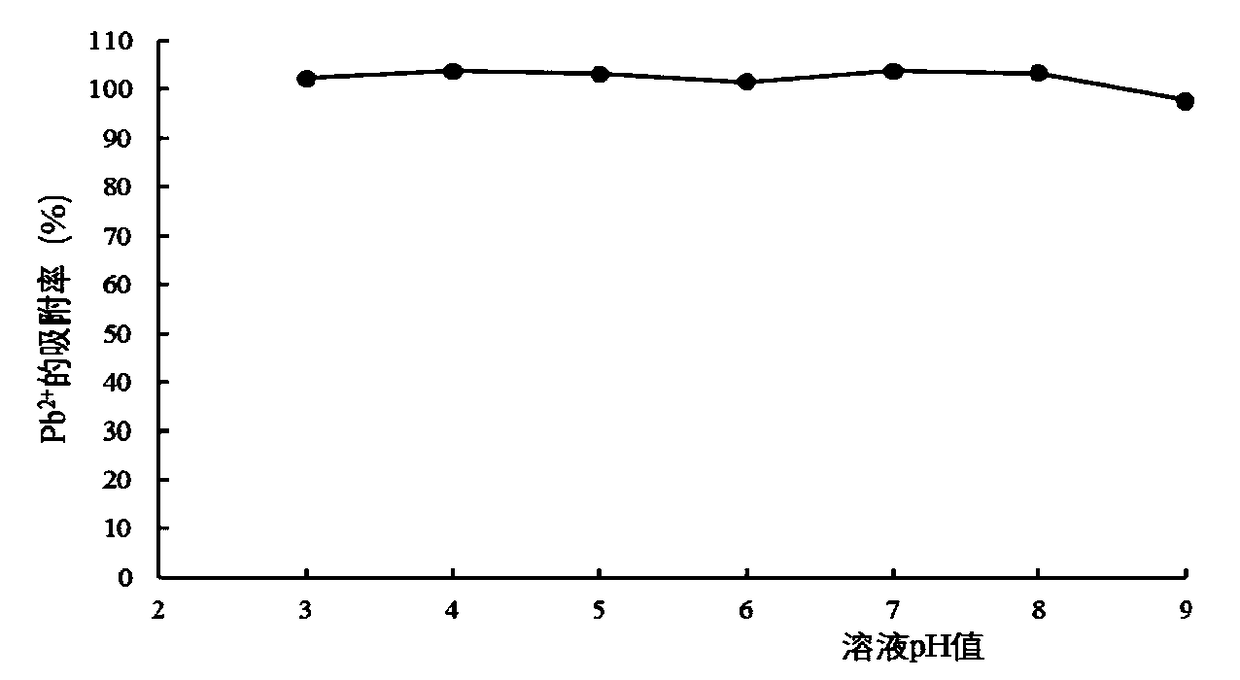

[0034] Adopt 0.1mol / L sodium hydroxide and 0.1mol / L nitric acid solution to make 100mg / L Pb 2+The solution was adjusted to pH 3, 4, 5, 6, 7, 8, and 9, respectively, and a certain amount of composite material 2 was weighed in Pb with different pH values. 2+ solution, so that the amount of addition is 0.8g / L, magnetic stirring is carried out at a speed of 250r / min, after adsorption for 30min, it is filtered through a 0.45μm filter membrane, each treatment is repeated 3 times, and the solution before and after adsorption is measured by atomic absorption spectrophotometry. Medium Pb 2+ concentration.

[0035] The result shows as figure 2 , when the pH value of the solution is between 3 and 8, Pb 2+ The adsorption rate is about 100%, ...

Embodiment 3

[0037] Take a water-soluble resin with a mass ratio of 10% and dissolve it in 20% water, then add 15% kaolin, 10% corn stalks, 40% nano-magnesium oxide and 5% gelatin in turn, mix well, and dry it at 450°C Calcined for 1 h, composite material 3 was obtained.

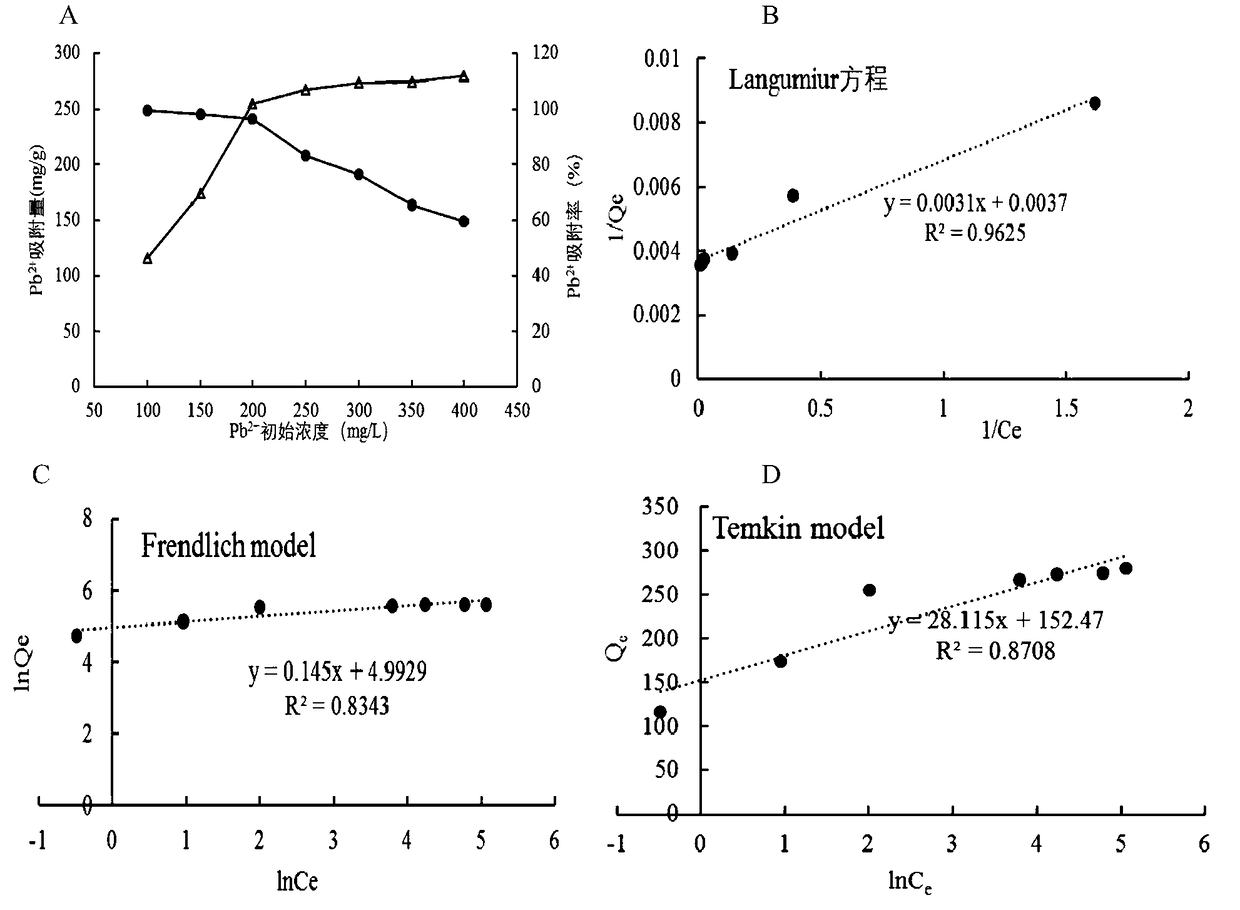

[0038] Prepare 100mg / L, 150mg / L, 200mg / L, 250mg / L, 300mg / L, 350mg / L and 400mg / L Pb respectively 2+ Solution, weigh a certain amount of composite material 3 and add different concentrations of Pb 2+ In the solution, make the addition amount 0.8g / L, carry out magnetic stirring, the speed is 250r / min, after adsorption for 30min, filter through 0.45μm filter membrane, each treatment is repeated 3 times, adopt atomic absorption spectrophotometry to measure adsorption Pb in solution 2+ concentration.

[0039] The result shows as image 3 A, △ is the adsorption rate curve, ○ is the adsorption capacity curve, when Pb 2+ When the concentration is 100-200mg / L, Pb 2+ The adsorption amount of Pb increases with the increase of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com