Method for efficiently producing phenylpyruvic acid

An amino acid and deaminase technology, applied in the field of bioengineering, can solve the problems of complex separation and purification process, low enzyme activity of metabolic pathway, low PAA yield, etc., and achieves the effect of simple purification, reduced production cost, and satisfied industrialization needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Acquisition of Proteus mirabilis amino acid deaminase gene

[0035] (1) Proteus mirabilis was inoculated in LB medium, cultured at 30°C for 16 hours to collect the bacteria, and the genomic DNA was extracted using a bacterial genome extraction kit.

[0036] (2) Use primers PM-1 (5'CGCGGATCCATGAACATTTCAAGGAGAAAGCTAC 3', sequence shown in SEQ ID NO:5) and PM-2 (5'CCGCTCGAGTTACTTCTTAAAACGATCCAAACTAA 3', sequence shown in SEQ ID NO:6) to clone from genomic DNA Obtaining the gene of amino acid deaminase;

[0037] (3) connecting the gene to a cloning vector for sequencing to obtain a gene sequence such as SEQ ID NO: 1, and a corresponding amino acid sequence such as SEQ ID NO: 3;

[0038] (4) Digest the target gene and expression vector pET20b at 37°C for 4 hours with restriction endonucleases BamH I and XhoI;

[0039] (5) Use T4 ligase to ligate the target gene and plasmid pET20b after digestion and gel recovery at 16°C overnight;

[0040] (6) Introduce the const...

Embodiment 2

[0041] Example 2: Protein Engineering Transformation of Proteus mirabilis Amino Acid Deaminase

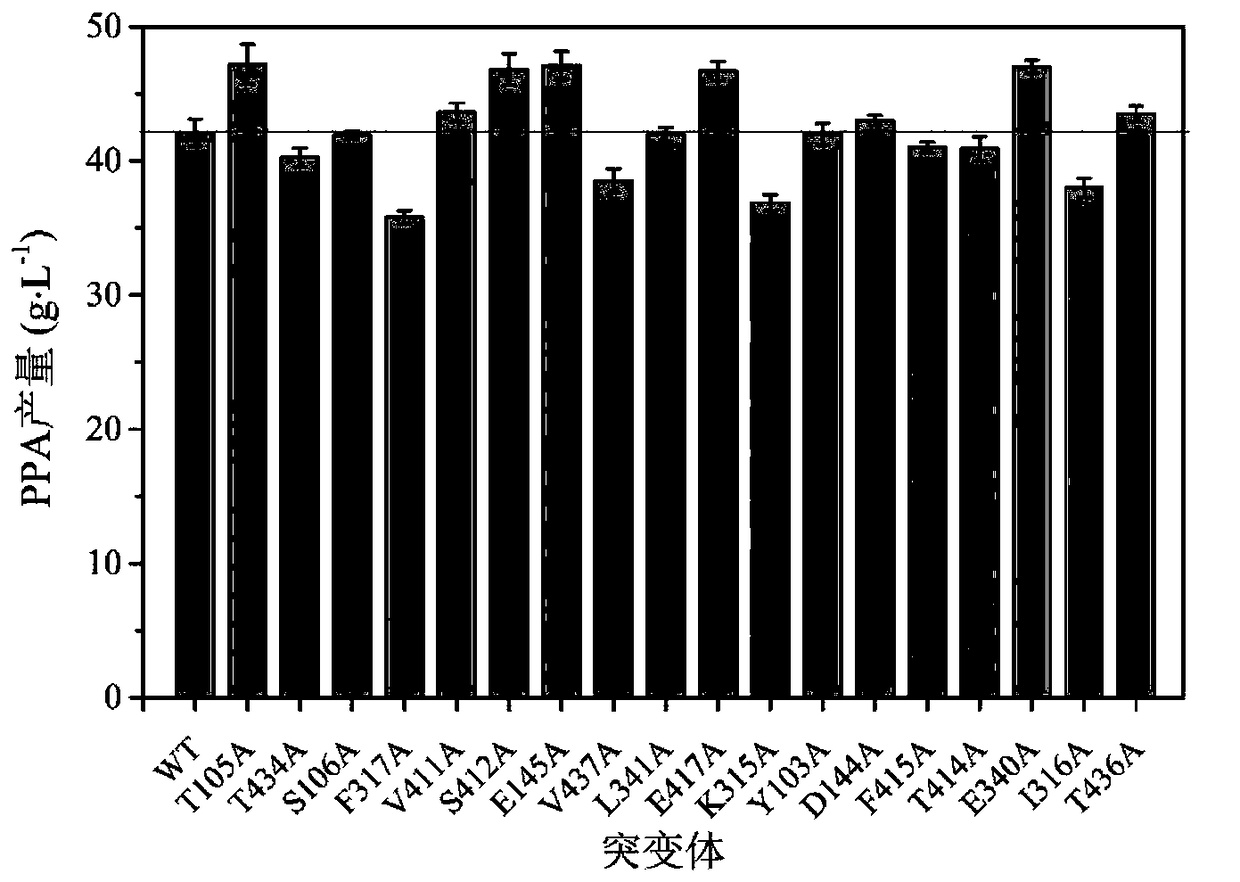

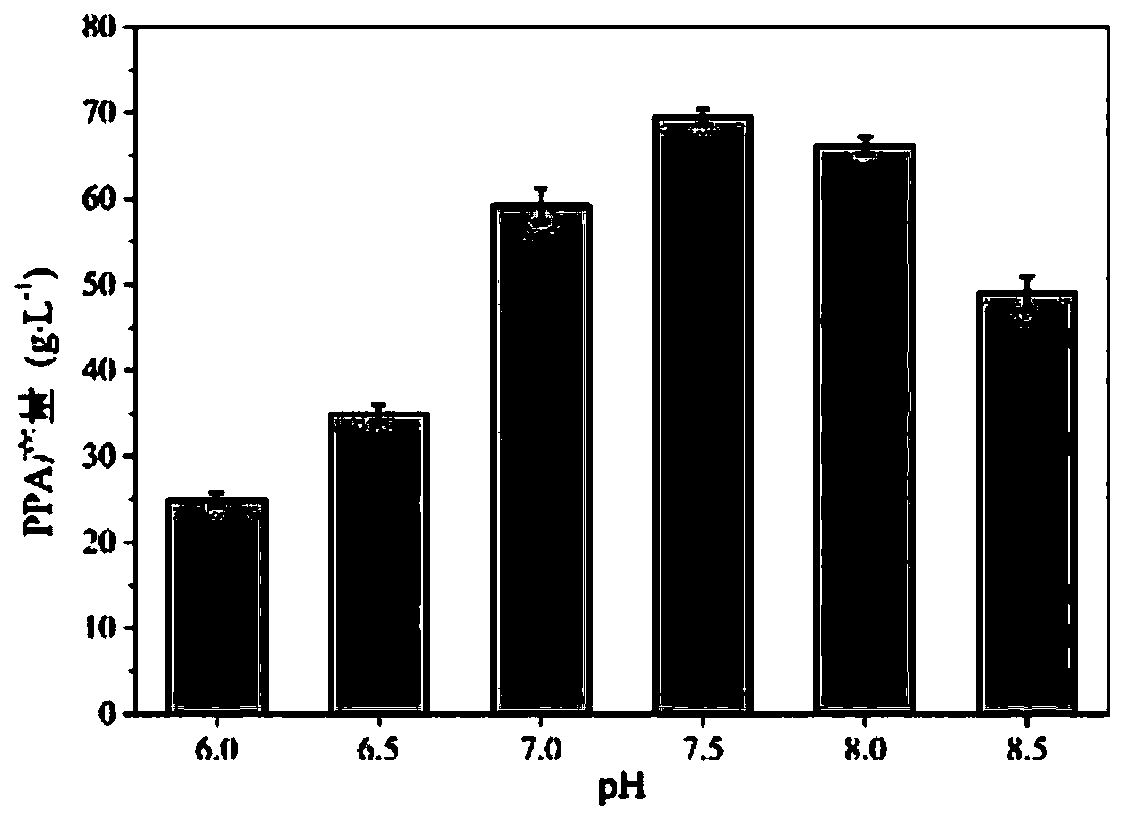

[0042] (1) In order to improve the catalytic performance of amino acid deaminase, the idea of conformational dynamics is applied, starting from the loop structure around the product, and adjusting the amino acids on the loop that have little influence on the structure, thereby increasing the conformational dynamics of the product binding site , promote product release, weaken product inhibition, and achieve the purpose of increasing production. A total of 18 amino acid sites (Y103 / T105 / S106 / D144 / E145 / R315 / I316 / F317 / E340 / L341 / V411 / S412 / T414 / F415 / E417 / T434 / T436 / V437) was mutated, mutated to alanine in turn, and a single mutant library was constructed by using the whole plasmid PCR method, and transformed into the host E.coli BL21(DE3), and the transformation experiment was carried out at the shake flask level, and the buffer system used 0.02mol of pH 7.5 / L Tris-HCl solution, add...

Embodiment 3

[0044] Example 3: Evaluation of amino acid deaminase mutants

[0045] (1) Seed medium formula: LB medium, yeast powder 5g / L, tryptone 10g / L, NaCl 10g / L.

[0046] Fermentation medium formula: glycerol 6g / L, yeast powder 15g / L, soybean peptone 15g / L, K 2 HPO 4 12H 2 O2.56g / L, KH 2 PO 4 10.0g / L.

[0047] The composition of feed medium is: glycerol 500g / L, yeast powder 15g / L, MgSO 4 ·7H 2 O 10g / L.

[0048] (2) E.coli BL21-PM and E.coli BL21-PM5 were inoculated in the fermentation medium according to 10% inoculum amount, the air volume was 1.0-2.0vvm, the temperature was 37°C, and the stirring rate was 600rpm and cultured to OD 600 At 8.0, lower the temperature to 25°C, add 10g / L lactose to induce the expression of amino acid deaminase, when OD 600 When it reaches 12.0-14.0, the dissolved oxygen suddenly rises, and feed feeding starts at this time, and the dissolved oxygen is related to the feeding, and the dissolved oxygen is controlled at 30-50%, and the fermentation is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com