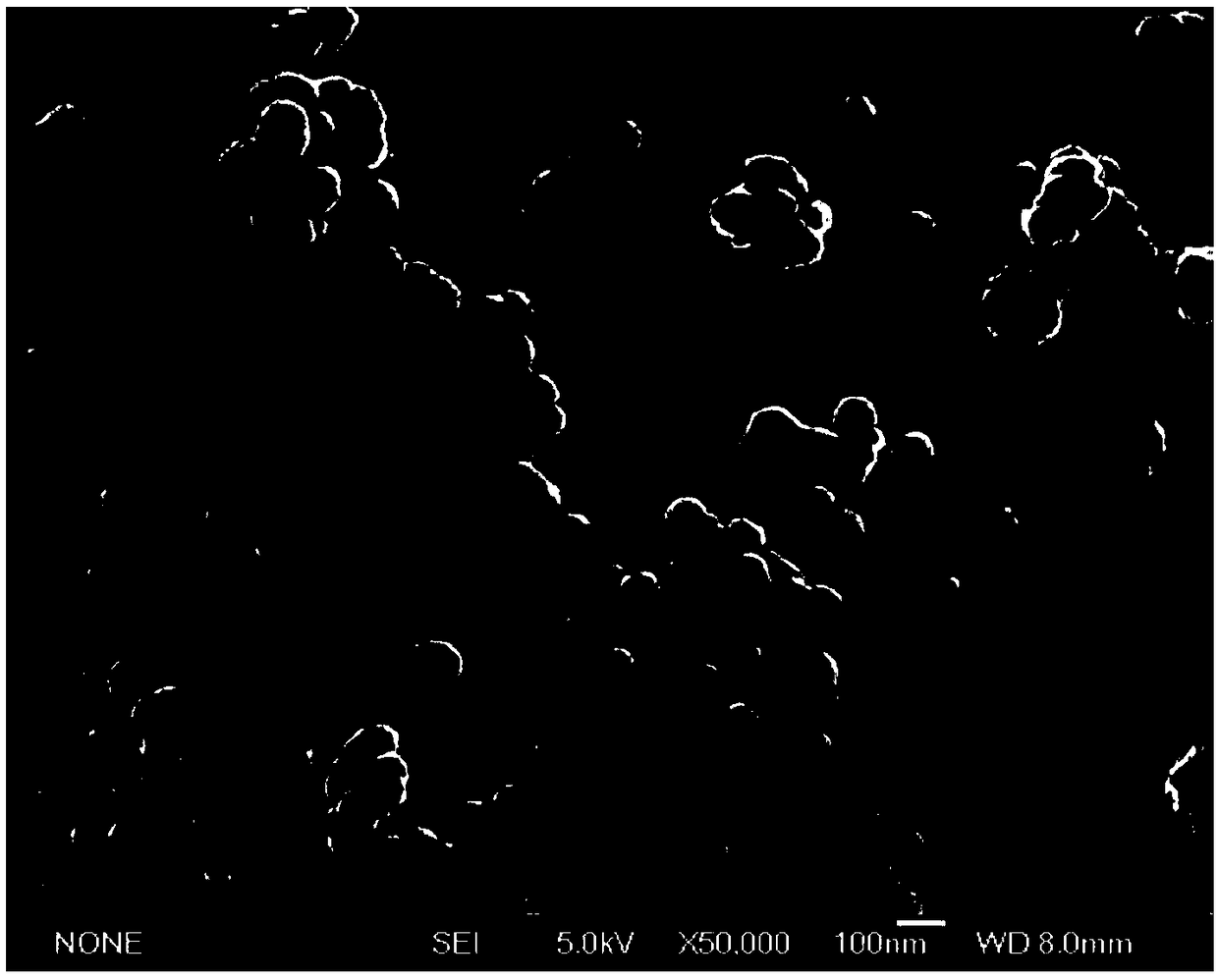

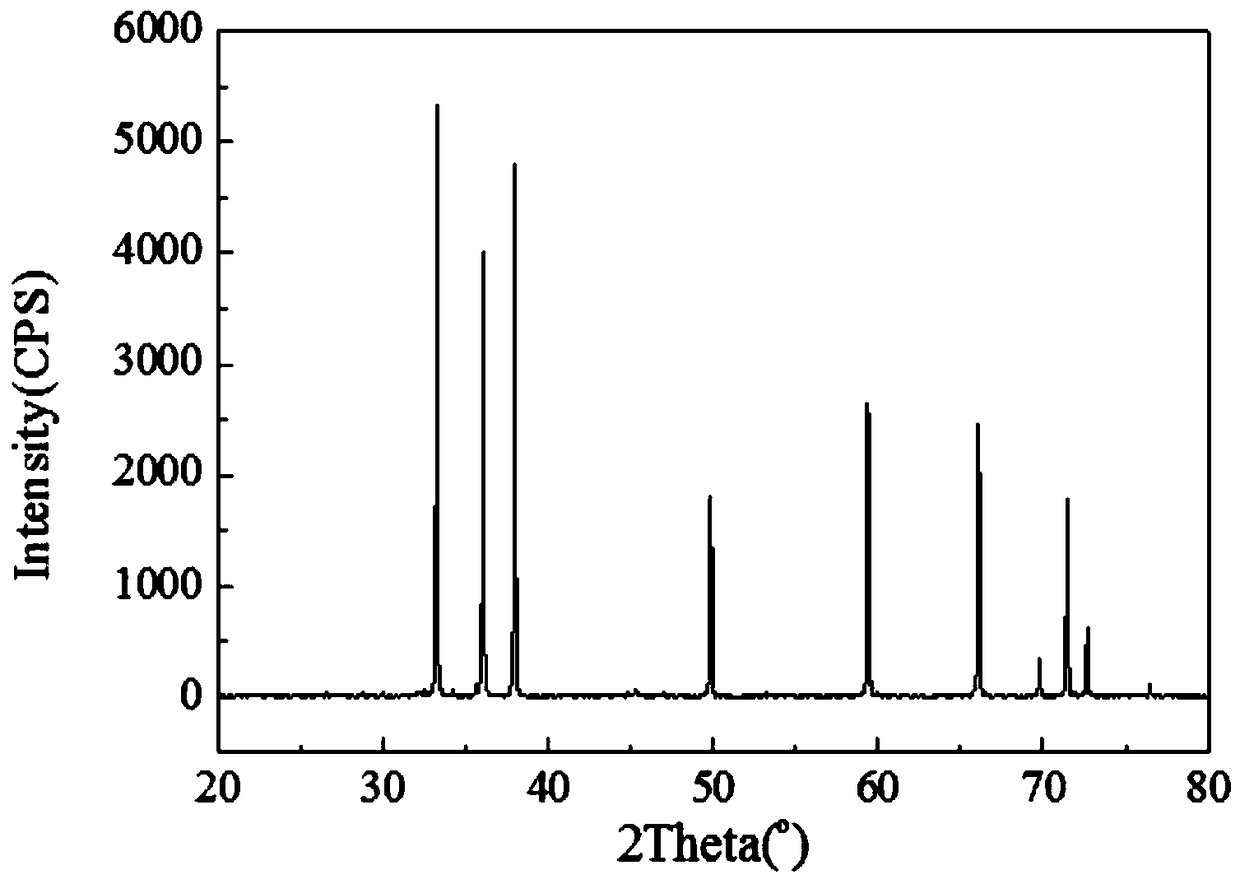

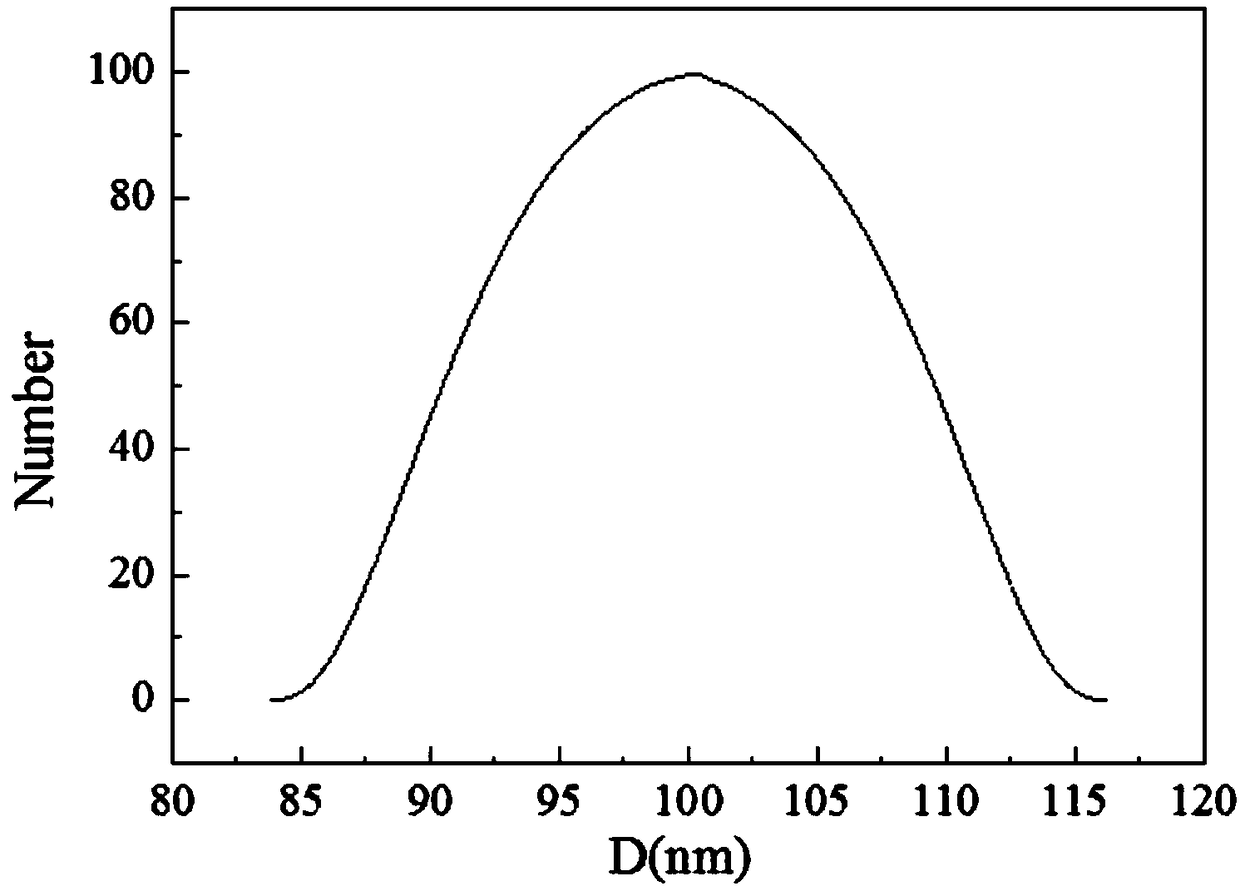

Preparation method of high-purity sphere-like nanometer AlN (aluminum nitride) particle

A technology of nano-aluminum nitride and spherical particles, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., to achieve the effects of low cost, narrow particle size distribution range, and wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The preparation method of high-purity, spherical nano-AlN comprises the following steps:

[0085] (1) Al 2 o 3 Powder: Ca(NO 3 ) 2 4H 2 O+Y(NO 3 ) 3 ·6H 2 O+KF: Water-soluble starch is weighed according to the mass ratio of 1:(0.15+0.2+0.05):4, mix the above materials, add a certain amount of water, the ratio of water to powder mass is 3:1, and use corundum The ball is used as the grinding medium, and the ball is milled in a corundum tank for 4 hours, and the speed of the ball mill is 400 rpm. After the ball milling, the slurry is sprayed and granulated to obtain fluffy micron-sized spherical particles. Aluminum oxide primary particles are accumulated;

[0086] (2) Transfer the micron-sized spherical particles into the corundum sagger, put the sagger into the microwave synthesis reaction chamber, use silicon carbide wafers as auxiliary heat, and inject atmospheric nitrogen to carry out powder synthesis. The synthesis process is divided into 2 stages: The first...

Embodiment 2

[0090] The preparation method of high-purity, spherical nano-AlN powder comprises the following steps:

[0091] (1) Al 2 o 3 Powder:Mg(NO 3 ) 2 +Gd(NO 3 ) 3 ·6H 2 O+NaF: sucrose is weighed according to the mass ratio of 1:(0.18+0.25+0.07):6, the above materials are mixed, a certain amount of water is added, the ratio of water to powder mass is 4.5:1, and corundum balls are used as Grinding media, ball milling in a corundum tank for 6 hours, the ball mill speed is 400 rpm, spray granulation of the slurry after ball milling, to obtain fluffy micron-sized spherical particles, the particles are wrapped by carbon precursor - soluble inorganic salt and alumina The accumulation of primary particles;

[0092] (2) Transfer the micron-sized spherical particles into the corundum sagger, put the sagger into the microwave synthesis reaction chamber, use silicon carbide wafers as auxiliary heat, and inject atmospheric nitrogen to carry out powder synthesis. The synthesis process is d...

Embodiment 3

[0096] The preparation method of high-purity, spherical nano-AlN comprises the following steps:

[0097] (1) Al 2 o 3 Powder: Ca(NO 3 ) 2 4H 2 O+Ce(NO 3 ) 3 ·6H 2 O+KF: Water-soluble dextrin is weighed according to the mass ratio of 1:(0.25+0.15+0.06):5.5, mix the above materials, add a certain amount of water, the ratio of water to powder mass is 5:1, use Corundum balls are used as grinding media, milled in a corundum tank for 6 hours, the speed of the ball mill is 400 rpm, and the slurry is sprayed and granulated after ball milling to obtain fluffy micron-sized spherical particles, which are soluble inorganic salts wrapped by carbon precursors Accumulated with alumina primary particles;

[0098] (2) Transfer the micron-sized spherical particles into the corundum sagger, put the sagger into the microwave synthesis reaction chamber, use silicon carbide wafers as auxiliary heat, and inject atmospheric nitrogen to carry out powder synthesis. The synthesis process is div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com