Polymer electrolyte with comb-shaped structure, and all-solid-state lithium battery

A comb-like structure and polymer technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, electrolyte, etc., can solve the problems of burning electrode active materials, electrochemical stability needs to be improved, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Under the protection of an argon atmosphere, PEGDMA and LiTFSI with a molecular weight of 480g / mol were weighed according to the EO / Li molar ratio of 18:1, and stirred evenly in the dark to obtain a casting solution; the casting solution was cast in a polytetrafluoroethylene mold, and UV light with a wavelength of 200nm was irradiated for 10 minutes to obtain poly-PEGDMA480, a polymer electrolyte film material.

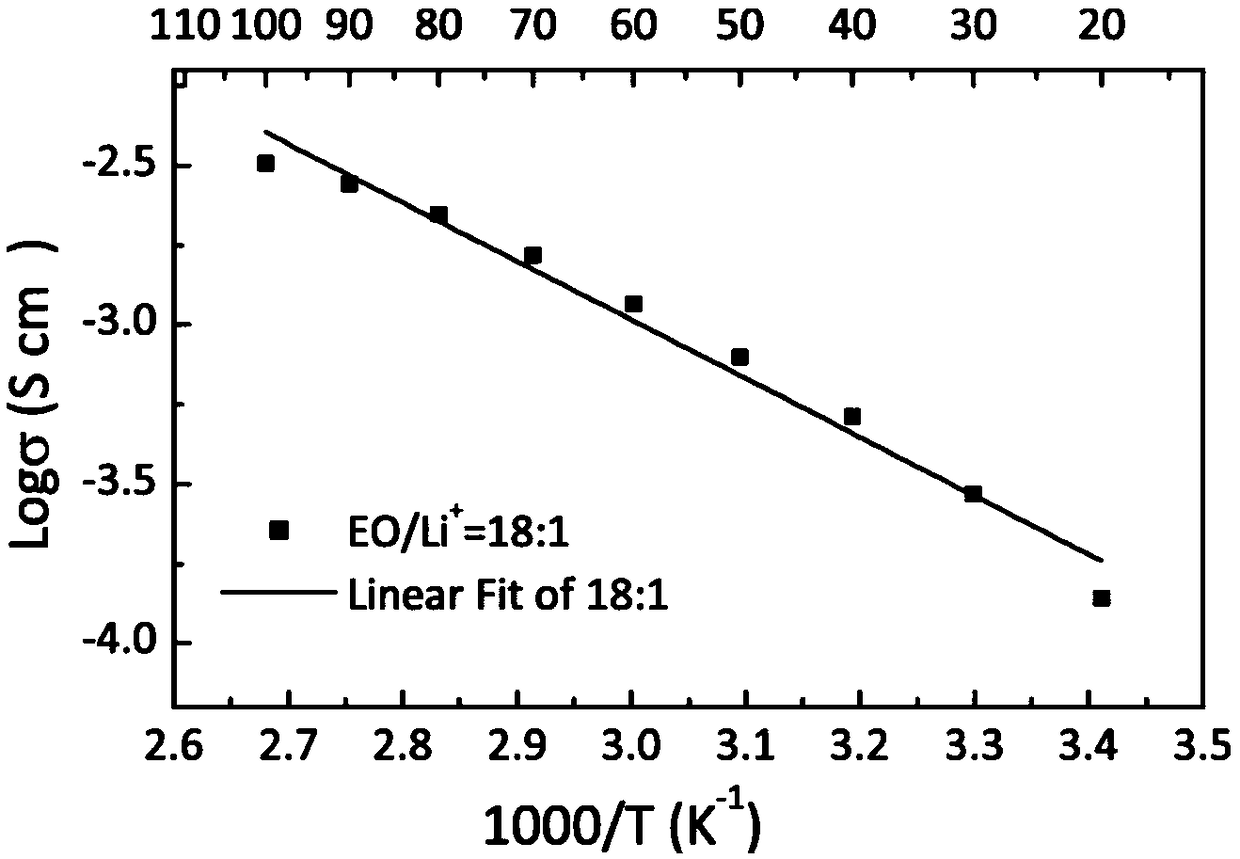

[0062] Using stainless steel as the blocking electrode, EIS tests were carried out at different temperatures to calculate its conductivity. The results are as follows: figure 1 shown. From figure 1 It can be seen from the figure that the ionic conductivity of this system is 3×10 at room temperature -4 S cm -1 .

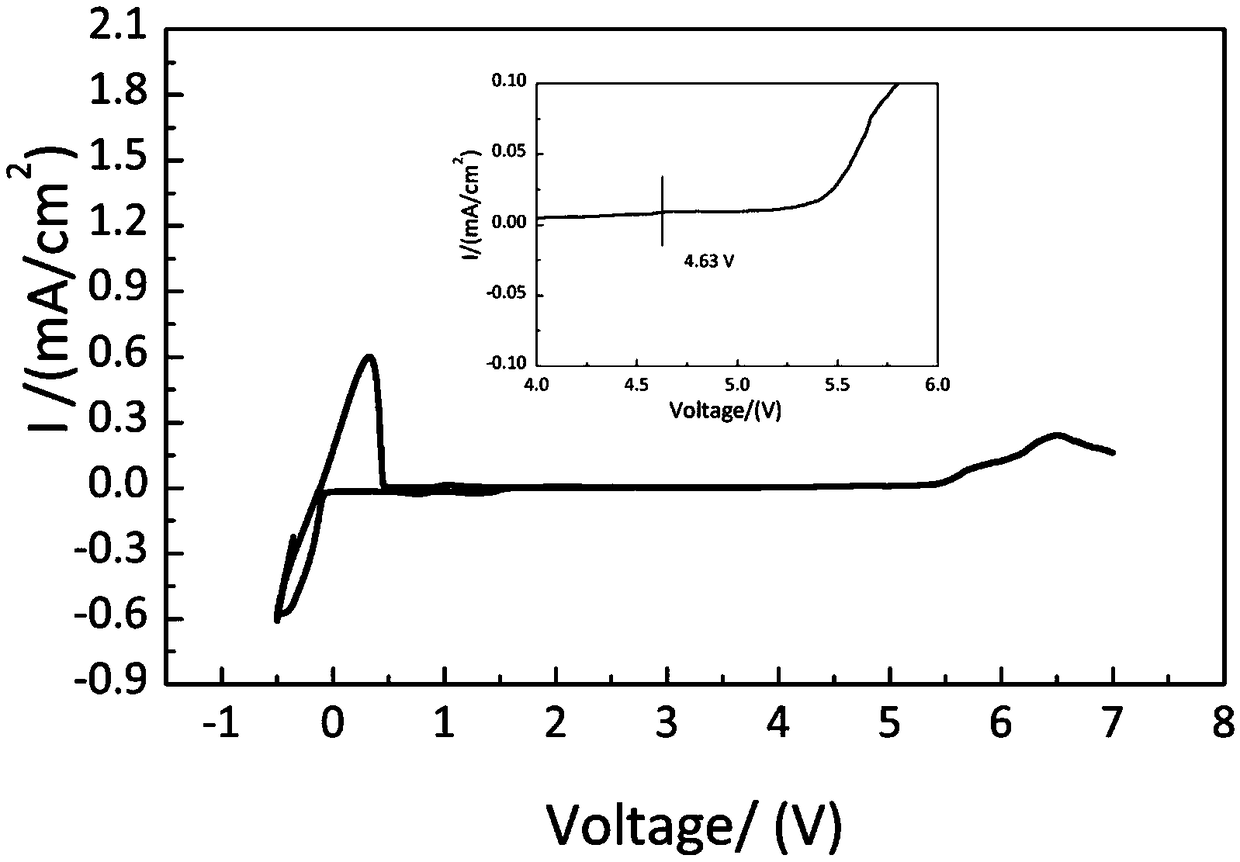

[0063] Assemble the battery with stainless steel as the working electrode and lithium as the counter electrode, and conduct CV and LSV tests at 80°C to test its electrochemical window, such as figure 2 as shown, figure 2 represents the oxidatio...

Embodiment 2

[0066] Under the protection of argon atmosphere, PEGDMA and PEGDA were mixed at a molar ratio of 1:1, LiTFSI was weighed according to the EO / Li molar ratio of 18:1, stirred in ACN, and the casting solution was cast on polytetrafluoroethylene after stirring evenly. Place in a vinyl mold at room temperature protected from light for 24 hours to volatilize the solvent, and then irradiate with a 500nm wavelength ultraviolet light for 240 minutes to obtain the polymer electrolyte film material poly-PEGDMA-PEGDA.

[0067] Using stainless steel as the blocking electrode, EIS tests were carried out at different temperatures to calculate its conductivity. At room temperature, the ionic conductivity of this system is 2.5×10 -4 S cm -1 .

[0068] The battery was assembled with stainless steel as the working electrode and lithium as the counter electrode. CV and LSV tests were performed at room temperature to test its electrochemical window. The electrochemical window of this system is 0-...

Embodiment 3

[0071] Under the protection of an argon atmosphere, PEGDMA with a molecular weight of 480g / mol and PEGDMA with a molecular weight of 950g / mol were mixed at a molar ratio of 1:1, and LiTFSI was weighed according to the EO / Li molar ratio of 18:1, stirred in ACN, and then stirred After uniformity, the casting solution was cast into a polytetrafluoroethylene mold, placed in a light-proof room temperature for 24 hours to evaporate the solvent, and then irradiated with a 300nm wavelength ultraviolet light for 100 minutes to obtain a polymer electrolyte film material poly-PEGDMA-PEGDMA.

[0072] Using stainless steel as the blocking electrode, EIS tests were carried out at different temperatures to calculate its conductivity. At room temperature, the ionic conductivity of the system was 9.09×10 -4 The electrochemical window is 0-5V, and has excellent electrochemical stability.

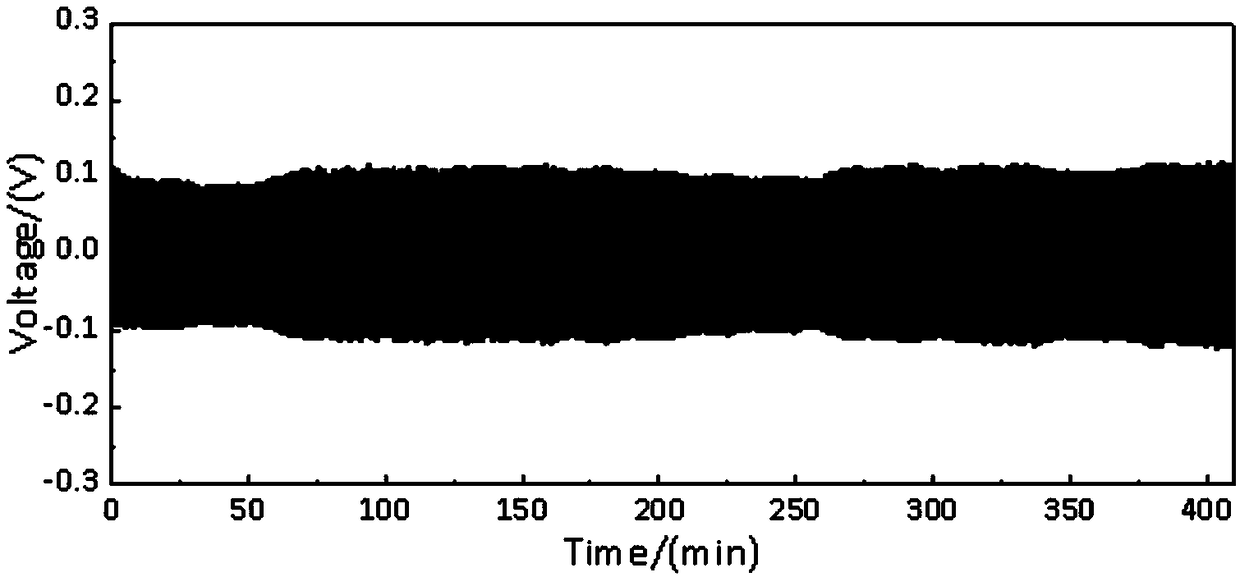

[0073] A symmetrical battery was assembled with lithium as the electrode, and the lithium stability test w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com