Cadmium contaminated mine soil remediation agent as well as preparation and application method thereof

A soil remediation agent, cadmium pollution technology, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve problems such as difficulty in soil remediation, achieve low cost, strong adsorption capacity, and solve the effect of physiological drought

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

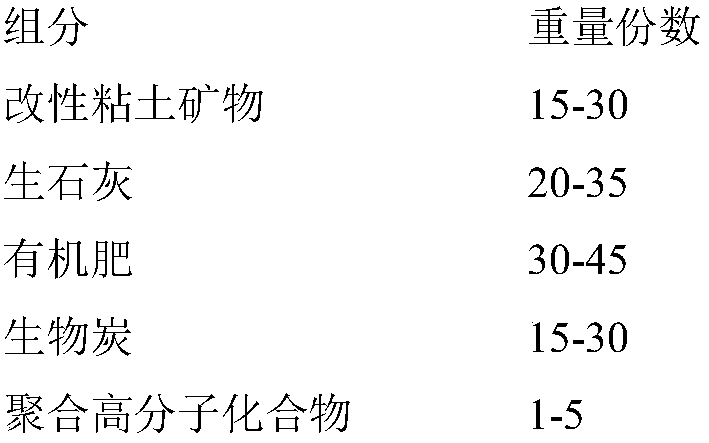

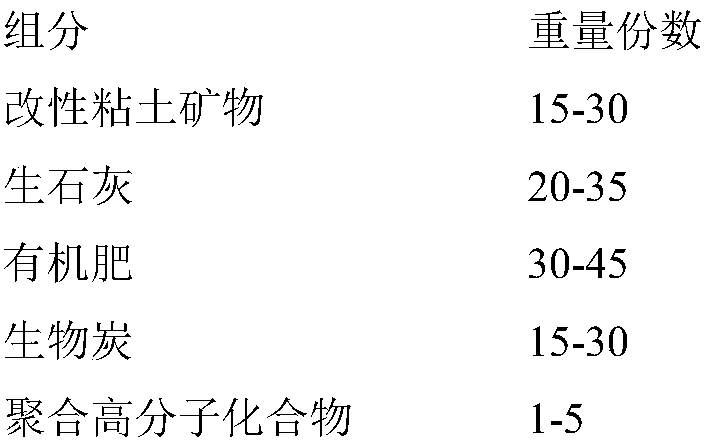

Method used

Image

Examples

example 1

[0034] Prepare the remediation agent for cadmium polluted mine soil according to the following steps:

[0035] Step 1: Preparation of modified clay minerals: Mix attapulgite, diatomaceous earth, and sepiolite in a ratio of 3:2:1, crush to 100 mesh, calcinate at 350°C for 1.5h, cool, and grind into particles or powder form.

[0036] Step 2: Preparation of organic fertilizer: use the fallen leaves of Pinghu Ecological Garden as the main raw material, add a mixture of chicken manure and pig manure at a ratio of 2:3, and inoculate the mixed bacteria solution including Bacillus, actinomycetes, yeast and lactic acid bacteria , used after 5d fermentation.

[0037] Step 3: Preparation of biochar: rice straw was used as raw material, pyrolyzed at 600°C, kept for 3 hours, cooled to room temperature, ground, and passed through a 100-mesh sieve.

[0038] Step 4: Evenly mix the modified clay mineral, quicklime, organic fertilizer, biochar, and polyglutamic acid at a ratio of 15:30:30:20:...

example 2

[0040] Prepare the remediation agent for cadmium polluted mine soil according to the following steps:

[0041] Step 1: Preparation of modified clay minerals: Mix attapulgite, diatomaceous earth, and sepiolite at a ratio of 4:2:3, crush to 100 mesh, calcinate at 400°C for 2 hours, cool, and grind into granules or powder shape.

[0042] Step 2: Preparation of organic fertilizer: use the shrubs and branches of Pinghu Ecological Garden as the main raw material, add a mixture of chicken manure and pig manure at a ratio of 1:5, and inoculate the mixture of Bacillus, actinomycetes, yeast and Trichoderma Bacterial solution, used after 7 days of fermentation.

[0043] Step 3: Preparation of biochar: rice straw was used as raw material, pyrolyzed at 600°C, kept for 3 hours, cooled to room temperature, ground, and passed through a 100-mesh sieve.

[0044] Step 4: Evenly mix the modified clay mineral, quicklime, organic fertilizer, biochar, and polyaspartic acid at the ratio of 20:24:35...

example 3

[0046] Prepare the remediation agent of cadmium polluted mine soil according to the following steps:

[0047] Step 1: Preparation of modified clay minerals: Mix attapulgite, sodium bentonite, and zeolite at a ratio of 5:3:2, crush to 100 mesh, calcinate at 350°C for 1.5h, cool, and grind into granules or powder .

[0048] Step 2: Preparation of organic fertilizer: use the fallen leaves of Pinghu Ecological Garden as the main raw material, add a mixture of chicken manure and pig manure at a ratio of 2:3, and inoculate the mixed bacteria solution including Bacillus, actinomycetes, yeast and lactic acid bacteria , used after 5d fermentation.

[0049] Step 3: Preparation of biochar: use corn stalks as raw materials, pyrolyze at 600°C, keep warm for 3 hours, cool to room temperature, grind, and pass through a 100-mesh sieve.

[0050] Step 4: Evenly mix the modified clay mineral, quicklime, organic fertilizer, biochar, and polymerized amino acid (1:1 mixture of polyaspartic acid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com