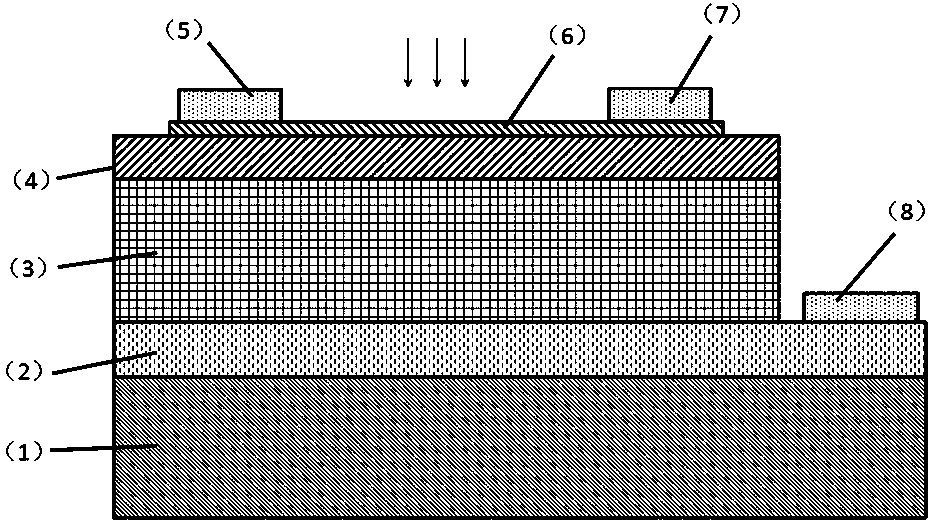

Grid-controlled graphene-based ultraviolet-to-near infrared InGaAs detector chip

A detector chip, alkenyl violet technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of large system size and weight, inability to detect ultraviolet light, complex detection system, etc., achieve high photocurrent signal gain and broaden the response Spectrum, the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

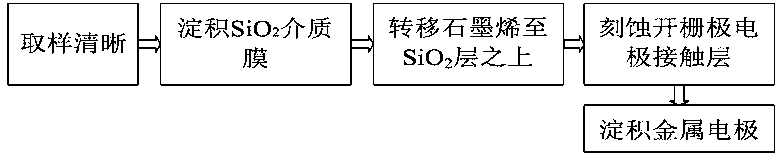

[0025] 1. Sampling and cleaning, using acetone, ethanol and deionized water to ultrasonically clean the sample for 8~3mins;

[0026] 2. Deposit the SiO2 dielectric layer 4 by plasma enhanced chemical vapor deposition (PECVD) technology to deposit the SiO2 dielectric layer 4 with a thickness of 90nm, the substrate temperature is 330±20°C, and the RF power is 40±10W;

[0027] 3. Transfer graphene 6, using dry transfer technology to transfer graphene with a thickness of 1 atomic layer onto the SiO2 dielectric layer 4;

[0028] 4. Etching the contact layer of the open gate electrode, using Ar ion etching technology for etching, the etching conditions are: ion energy 150-400eV, beam current 40-80cm -3 ;

[0029] 5. Deposit metal electrodes, using ion beam sputtering process to deposit metal electrodes, vacuum degree is 2~5×10 -2 Pa, the ion beam energy is 100 eV ~250eV;

[0030] 6. Test results: The response band of the detector covers 375nm~1700nm, and the response rate can rea...

Embodiment 2

[0032] 1. Sampling and cleaning, using acetone, ethanol and deionized water to ultrasonically clean the sample for 8~3mins;

[0033] 2. Deposit SiO2 dielectric layer 4 by plasma enhanced chemical vapor deposition (PECVD) technology to deposit SiO2 dielectric layer 4 with a thickness of 300nm, the substrate temperature is 330±20°C, and the RF power is 40±10W;

[0034] 3. Transfer graphene 6, using dry transfer technology to transfer graphene with a thickness of 3 atomic layers to the SiO2 dielectric layer 4;

[0035] 4. Etching the contact layer of the open gate electrode, using Ar ion etching technology for etching, the etching conditions are: ion energy 150-400eV, beam current 40-80cm -3 ;

[0036] 5. Deposit metal electrodes, using ion beam sputtering process to deposit metal electrodes, vacuum degree is 2~5×10 -2 Pa, the ion beam energy is 100 eV ~250eV;

[0037] 6. Test results: The response band of the detector covers 375nm~1700nm, and the response rate can reach 140A / ...

Embodiment 3

[0039] 1. Sampling and cleaning, using acetone, ethanol and deionized water to ultrasonically clean the sample for 8~3mins;

[0040] 2. Deposit the SiO2 dielectric layer 4 by plasma enhanced chemical vapor deposition (PECVD) technology to deposit the SiO2 dielectric layer 4 with a thickness of 90nm, the substrate temperature is 330±20°C, and the RF power is 40±10W;

[0041] 3. Transfer graphene 6, using dry transfer technology to transfer graphene with a thickness of 5 atomic layers to the SiO2 dielectric layer 4;

[0042] 4. Etching the contact layer of the open gate electrode, using Ar ion etching technology for etching, the etching conditions are: ion energy 150-400eV, beam current 40-80cm -3 ;

[0043] 5. Deposit metal electrodes, using ion beam sputtering process to deposit metal electrodes, vacuum degree is 2~5×10 -2 Pa, the ion beam energy is 100 eV ~250eV;

[0044] 6. Test results: The response band of the detector covers 375nm~1700nm, and the response rate can reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com