Transition metal sulfide composite electrode material and preparation method thereof and fully-solid-state lithium battery

A transition metal, composite electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the decline of the overall performance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention provides a method for preparing a transition metal sulfide composite electrode material described in the above technical solution, comprising the following steps:

[0056] Mix transition metal sulfides and anhydrous organic solvents and stir to obtain a suspension; the transition metal sulfides are selected from iron-based polysulfides, cobalt-based polysulfides, nickel-based polysulfides and vanadium-based polysulfides one or more of

[0057]Mix the solid electrolyte raw material and the suspension, conduct a precipitation reaction under sealed conditions, distill under reduced pressure, and dry to obtain a precursor; the solid electrolyte raw material is selected from a mixture including lithium sulfide and phosphorus pentasulfide; or Li 10 GeP 2 S 12 Ternary electrolyte;

[0058] The precursor is annealed to obtain a transition metal sulfide composite electrode material.

[0059] The invention adopts a precipitation method to obtain a transi...

Embodiment 1

[0071] 4mmol FeSO 4 ·7H 2 O was added to 40mL N,N-dimethylformamide and 30mL ethylene glycol mixed solvent, stirred at room temperature for 1.0h until completely dissolved to obtain a mixed solution; then urea was added to the above mixed solvent and stirred magnetically for 0.5h. Finally, under the protection of argon atmosphere, 20 mmol of sublimed sulfur was added to it, and reacted in a three-necked flask at 180 ° C for 8 h, the black precipitate was washed by centrifugation, and after freeze-drying at -40 ° C for 24 h, the iron disulfide electrode material was obtained;

[0072] Add 0.5g of iron disulfide prepared above into 20mL of anhydrous acetonitrile, then weigh lithium sulfide and phosphorus pentasulfide into the above solution according to the molar ratio of 7:3, stir evenly at room temperature and transfer to the reactor to seal; React in an oil bath at 50°C for 24h; evaporate the remaining solvent under reduced pressure, and dry in an inert atmosphere; anneal th...

Embodiment 2

[0075] 0.1mmol of Co(NO 3 ) 2 ·6H 2 O and 0.5 mmol thioacetamide were simultaneously added to a mixed solvent of 40 mL of absolute ethanol and 40 mL of deionized water, and magnetically stirred at room temperature for 1.0 h until uniformly mixed. Then transfer it to a reaction kettle for 12 hours at 160°C. After cooling down to room temperature naturally, the black precipitate was centrifuged and washed, and freeze-dried for 24 hours to obtain a cobalt disulfide electrode material whose microscopic morphology is a cobalt disulfide electrode material of nanoparticles;

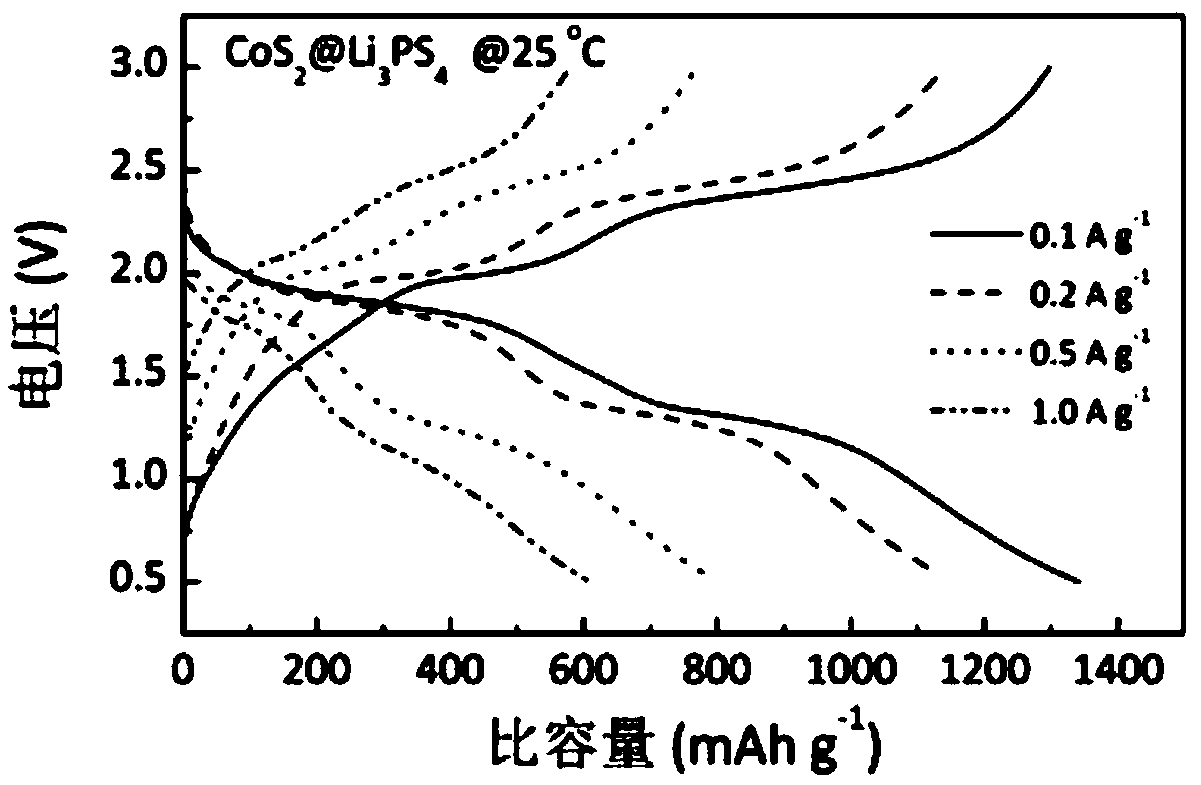

[0076] Add the 0.5g cobalt disulfide prepared above into 20mL tetrahydrofuran, then weigh lithium sulfide and phosphorus pentasulfide according to the molar ratio of 3:1 and add them to the above solution, stir evenly at room temperature and transfer to the reactor to seal; React in an oil bath at 50°C for 24h, then evaporate the remaining solvent under reduced pressure, and dry in an inert atmosphere; finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com