Organic/inorganic composite solid-state electrolyte based on quasi-one-dimensional oxide and its application

A solid electrolyte, inorganic composite technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of inability to fully enhance ionic conductivity, reduce the mechanical properties of electrolyte membranes, and affect the safety of lithium-ion batteries, and achieve good results. The effect of rate and cycle performance, low cost, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 3g of polypropylene carbonate, 0.3g of lithium bistrifluoromethanesulfonimide, and 0.3g of rod-shaped titanium dioxide with a diameter of about 120nm and a length of 10 to 20um to 20g of N-methylpyrrolidone in sequence, and stir for 24 hour to uniform;

[0030] (2) The carrier is a stainless steel plate, and the above solution is formed into a film by scraping, and the wet film thickness is 150um;

[0031] (3) After the wet film was naturally dried for 30 minutes, it was transferred to a vacuum drying oven and dried at 100°C for 24 hours to obtain a composite electrolyte membrane with a thickness of 60±3um.

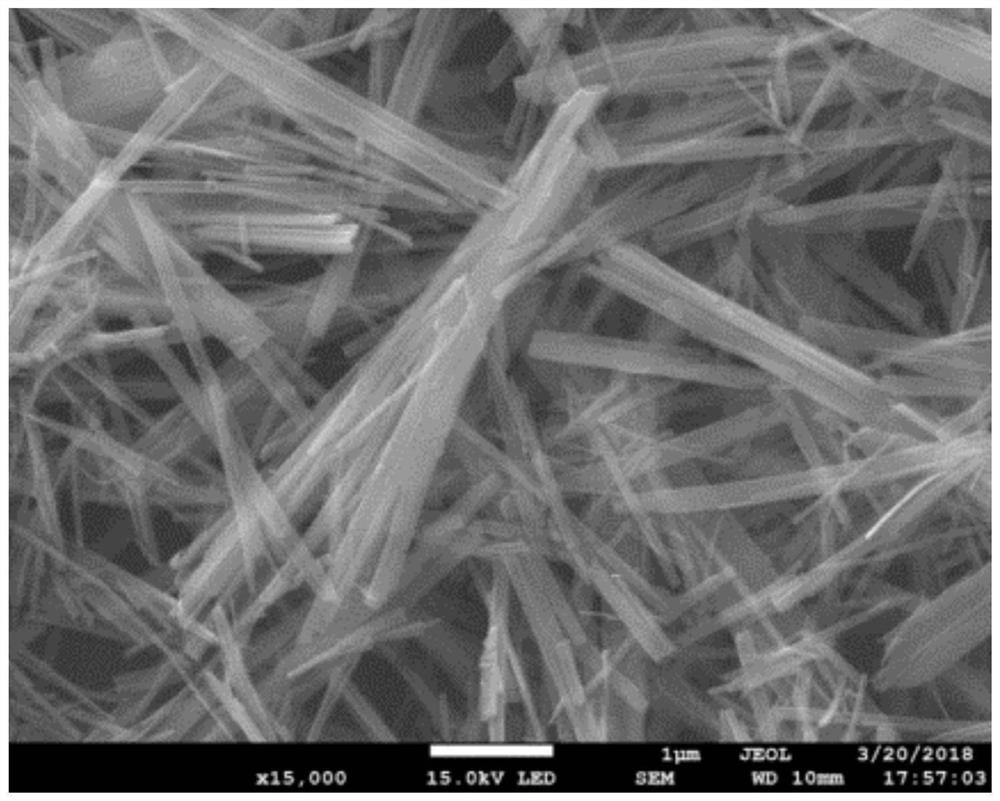

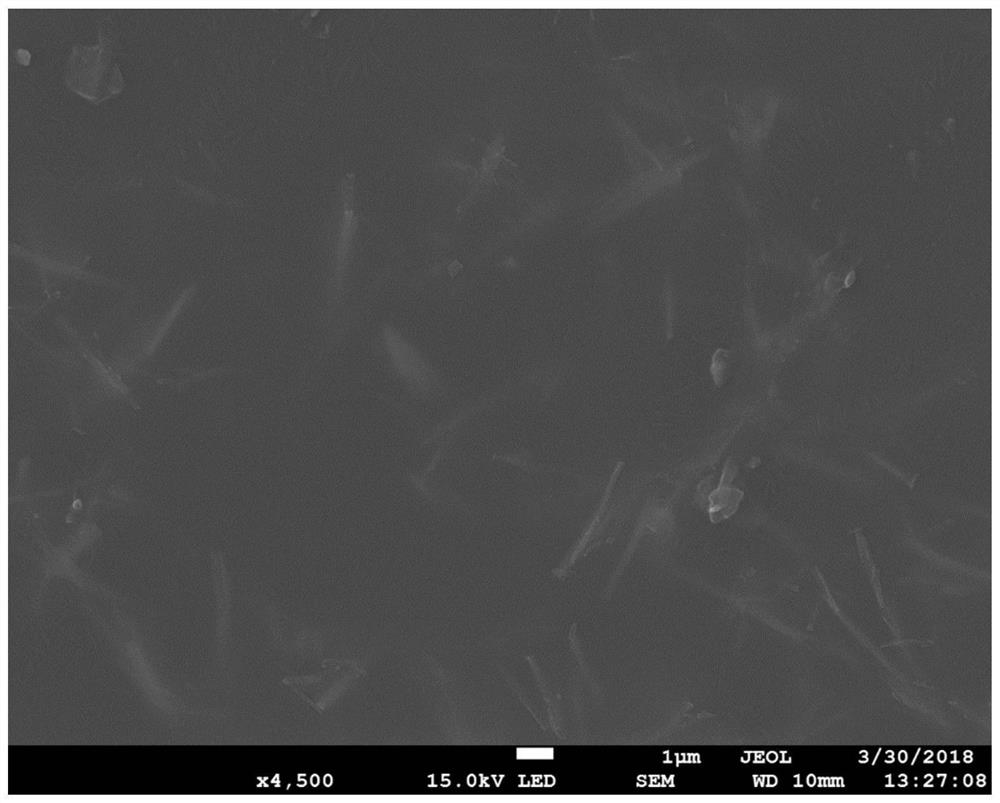

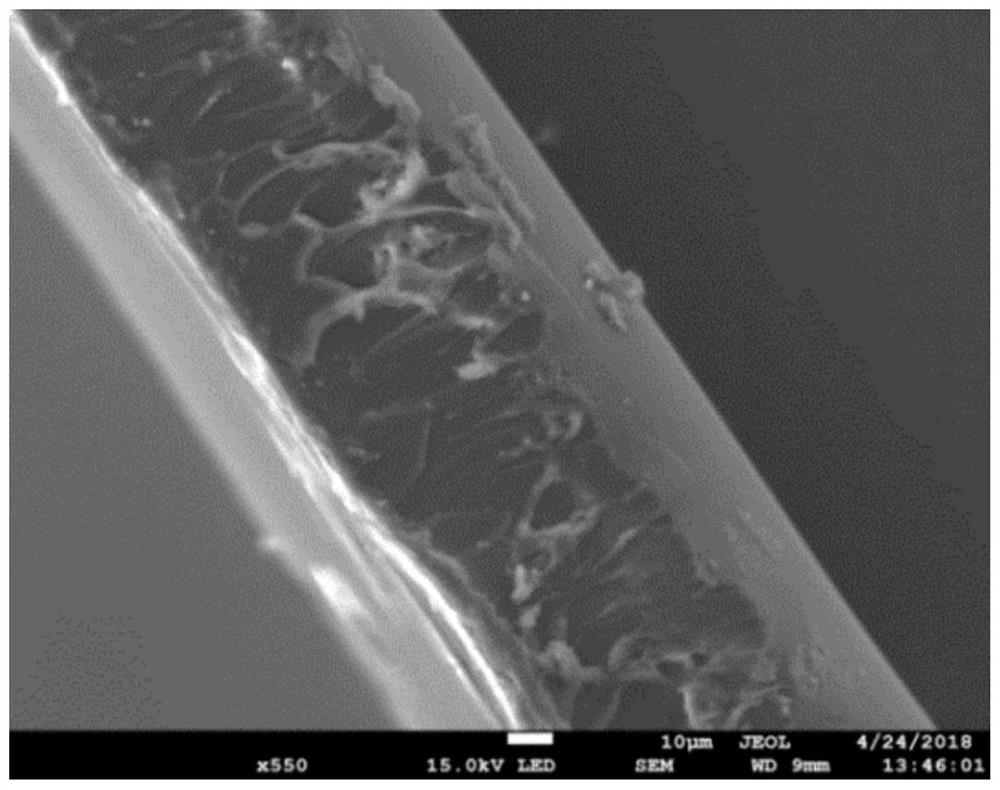

[0032] figure 1 It is the SEM photo of the rod-shaped titanium oxide filler used. It can be seen that the quasi-one-dimensional structure is very obvious, with a diameter of about 120nm and a length of 10-20um. Depend on figure 2 , 3 The scanning electron microscope photos of the composite electrolyte membrane show that the surface of the composite elec...

Embodiment 2

[0034] (1) Add 3g of polybutylene carbonate, 0.15g of lithium bistrifluoromethanesulfonimide, and 0.9g of fibrous alumina with a diameter of about 500nm and a length of 150 to 180um into 30g of acetone, and stir for 24 hour to uniform;

[0035] (2) The carrier is a polytetrafluoroethylene plate, and the above solution is sprayed to form a film, and the wet film thickness is 300um;

[0036] (3) After the wet film was naturally dried for 30 minutes, it was transferred to a vacuum drying oven and dried at 100°C for 24 hours to obtain a composite electrolyte membrane with a thickness of 165±3um.

[0037] The fibrous alumina filler used in this example has a diameter of about 500nm and a length of 150-180um. The surface of the formed composite electrolyte membrane is very smooth and uniform, the cross-sectional structure is dense, the potential window reaches 4.0V, and the ion conductivity is 1.6×10 -4 S / cm, the tensile strength is 5MPa as measured by a universal testing machine. ...

Embodiment 3

[0039] (1) Add 10g of polyvinyl carbonate, 3g of lithium perchlorate, and 1g of rod-shaped silica with a diameter of about 80nm and a length of 5-8um to 10g of N-N dimethylformamide in sequence, and stir for 24 hours until uniform;

[0040] (2) The carrier is a silica gel plate, and the above solution is formed into a film by roller coating, and the wet film thickness is 100 um.

[0041](3) After the wet film was naturally dried for 30 minutes, it was transferred to a vacuum drying oven and dried at 100°C for 24 hours to obtain a composite electrolyte membrane with a thickness of 52±2um.

[0042] The diameter of the rod-shaped silica filler used in this example is about 80nm, and the length is 5-8um. The surface of the formed composite electrolyte membrane is very smooth and uniform, the cross-sectional structure is dense, the potential window reaches 4.5V, and the ion conductivity is 4.6×10 -4 S / cm, the tensile strength is 17MPa as measured by a universal testing machine. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com