Preparation method for high specific surface area wet oxidation catalyst

A high specific surface area, wet oxidation technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low COD removal efficiency, affecting catalyst performance and activity To reduce the loss of copper ions, improve the strength and reduce the loss of copper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

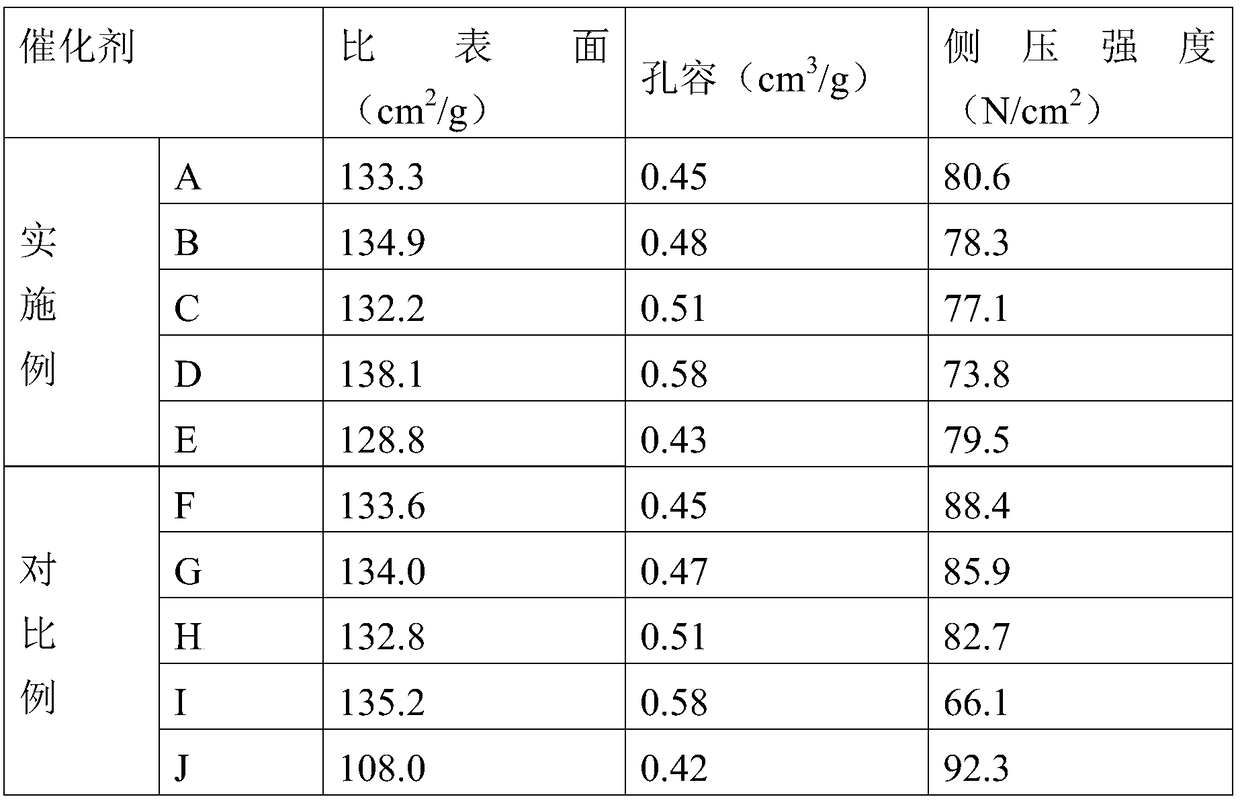

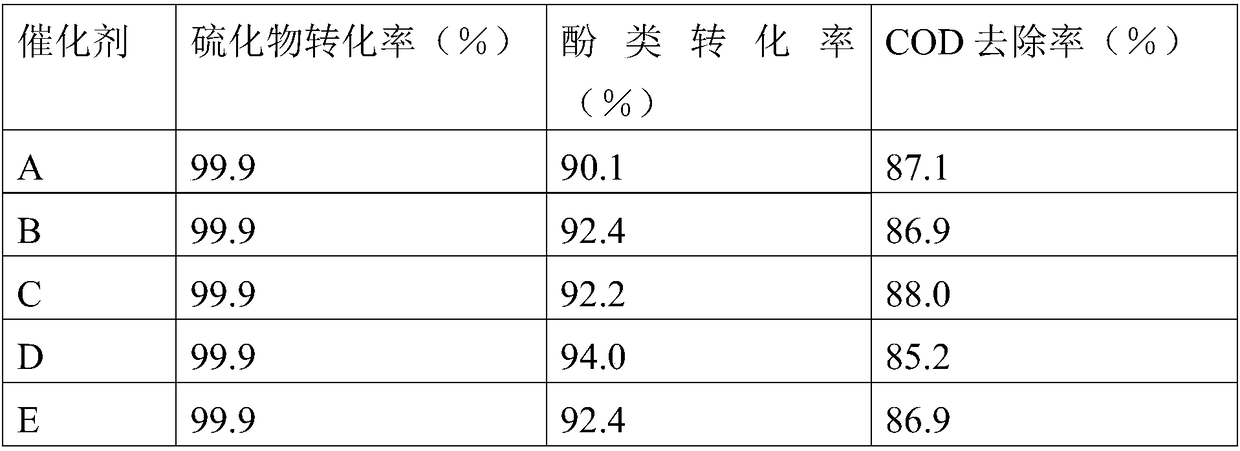

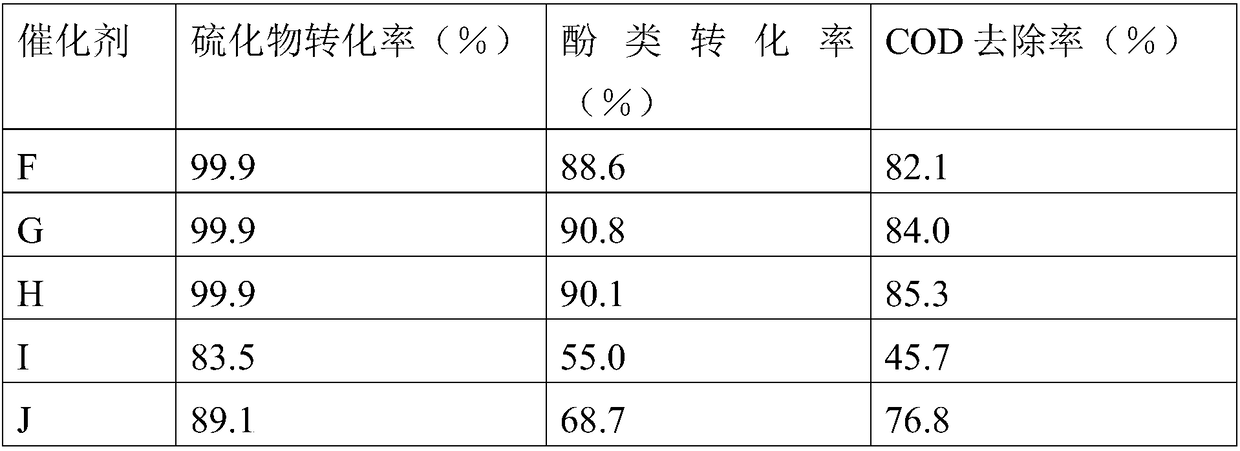

Embodiment 1

[0033] 30g of activated carbon was impregnated with 5% glucose and beaten to form a slurry with a carbon content of 100g / L, adding copper nitrate solution containing 30g of CuO, ultrasonically oscillating for 2 hours, then gradually adding ammonia water to adjust the pH value to 8.0, after precipitation, filter, Washing; then use deionized water to make a slurry with a water content of 50%, add 10g of nickel nitrate solution in terms of NiO, stir while ultrasonically oscillating for 1.5h, and dry directly at 600°C in an inert gas environment Roasting for 2 hours; after roasting, the powder is then mixed with 10g of CeO cerium nitrate solution to make a slurry with a water content of 30%, after stirring, add 1g of urea, stir for 40min, seal and stand for 24h, dry, and in an inert gas environment at 650°C Wet oxidation catalyst sample A was obtained after calcination for 7 hours.

Embodiment 2

[0037] Impregnate 20g of activated carbon with 12% glucose and beat to form a slurry with a carbon content of 200g / L, add copper nitrate solution containing 30g of CuO, and gradually add ammonia water to adjust the pH value to 9.0 after ultrasonic vibration for 1 hour. After the precipitation is complete, filter , washing; then the washed material is made into a slurry with a water content of 50% with deionized water, and 20 g of nickel nitrate solution in terms of NiO is added, and ultrasonic vibration is performed for 1.5 h while stirring. Roast at ℃ for 2h; after roasting, the powder is mixed with 5g of CeO cerium nitrate solution to make a slurry with a water content of 30%, after stirring, add 1g of Tianqing powder, stir for 40min, seal and stand for 24h, dry, and inert gas environment Wet oxidation catalyst sample B was obtained after calcination at 600°C for 5 hours.

Embodiment 3

[0041] Impregnate 40g of activated carbon with 10% glucose and beat to form a slurry with a carbon content of 300g / L, add copper nitrate solution containing 30g of CuO, and gradually add ammonia water to adjust the pH value to 10.0 after ultrasonic oscillation for 2 hours. After the precipitation is complete, filter , washing; then the washed material is made into a slurry with a water content of 50% with deionized water, and 20g of nickel nitrate solution in terms of NiO is added, and ultrasonic vibration is performed for 1.5h while stirring. Roast at ℃ for 2h; after roasting, the powder is mixed with 10g of cerium nitrate solution calculated as CeO to make a slurry with a water content of 30%, after stirring, add 1g of Tianqing powder, stir for 40min, seal and stand for 24h, dry, and inert gas environment Wet oxidation catalyst sample C was obtained after calcination at 550°C for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com