Selenium-zinc-calcium compound chewable tablets, and preparation method and applications thereof

A technology of chewable tablets and zinc-calcium, which is applied in the field of selenium-zinc-calcium chewable tablets and its preparation, can solve the problems of selenium deficiency onset hidden and difficult to be found, etc., to prevent human cell damage, easy to carry and store, Ease of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

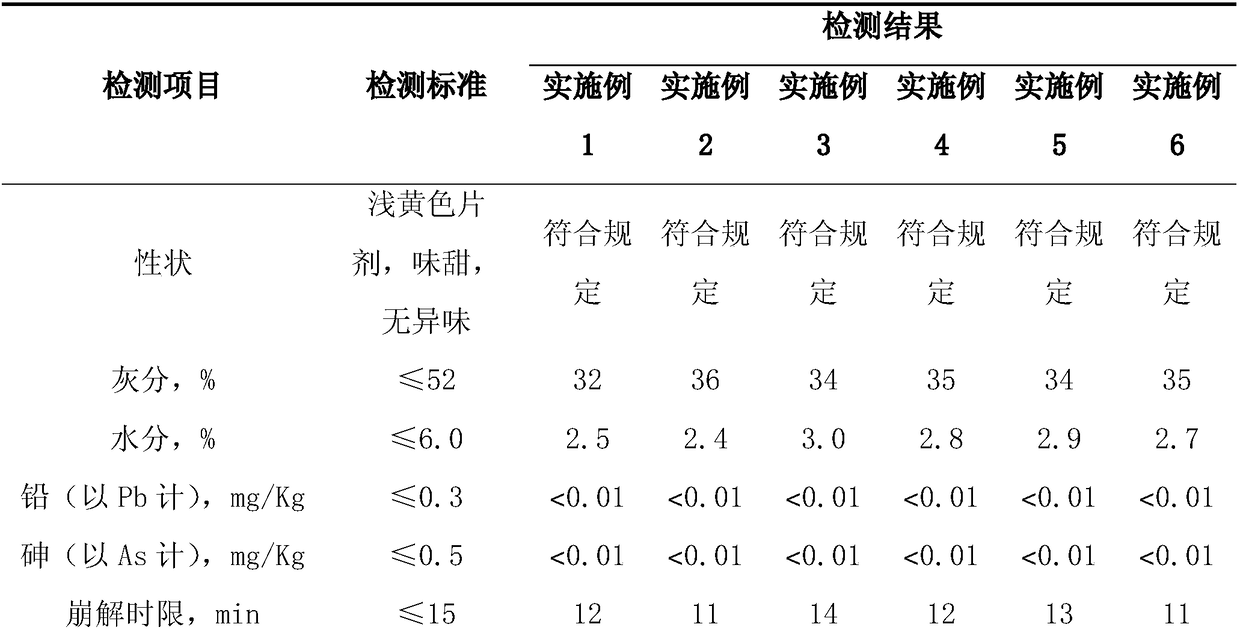

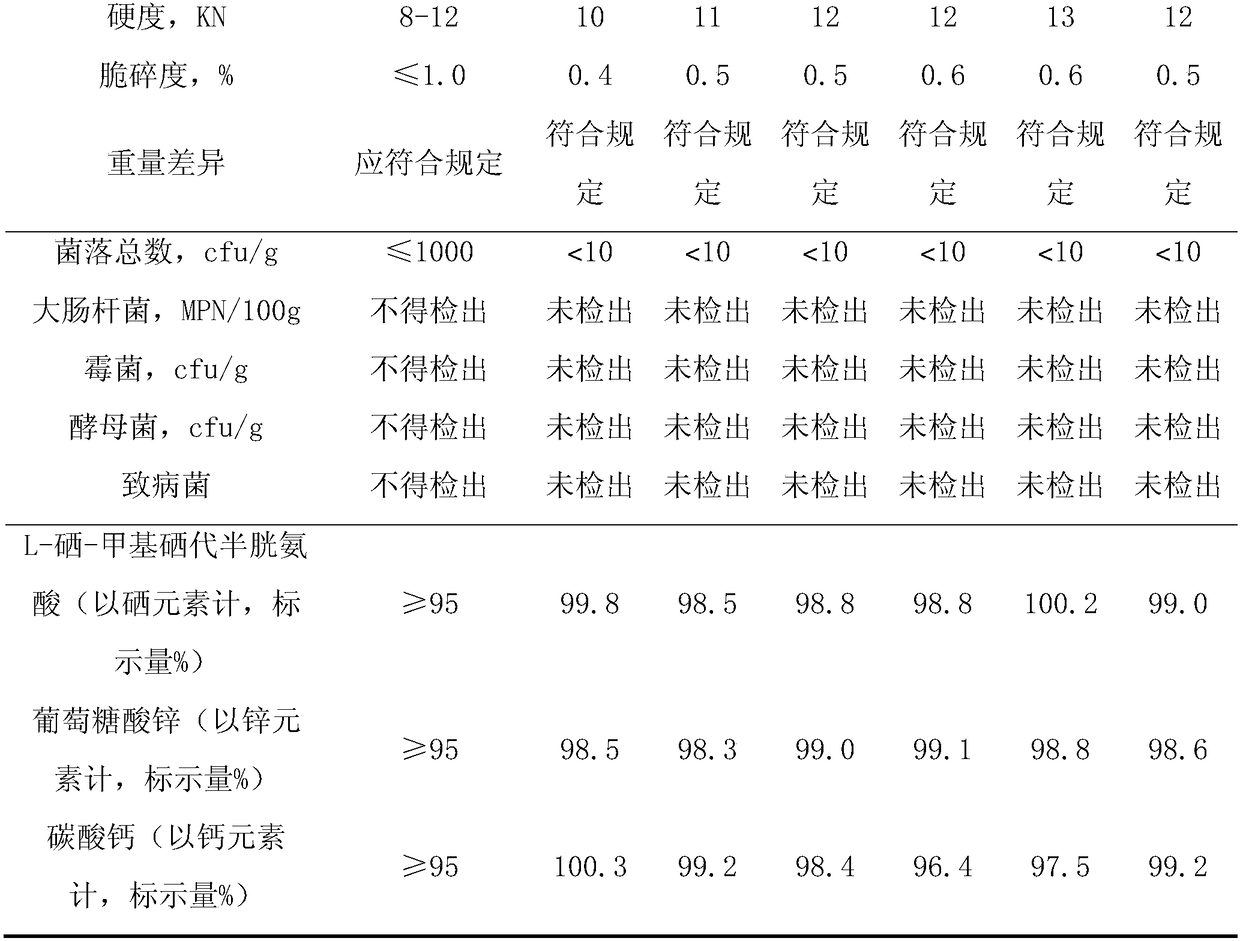

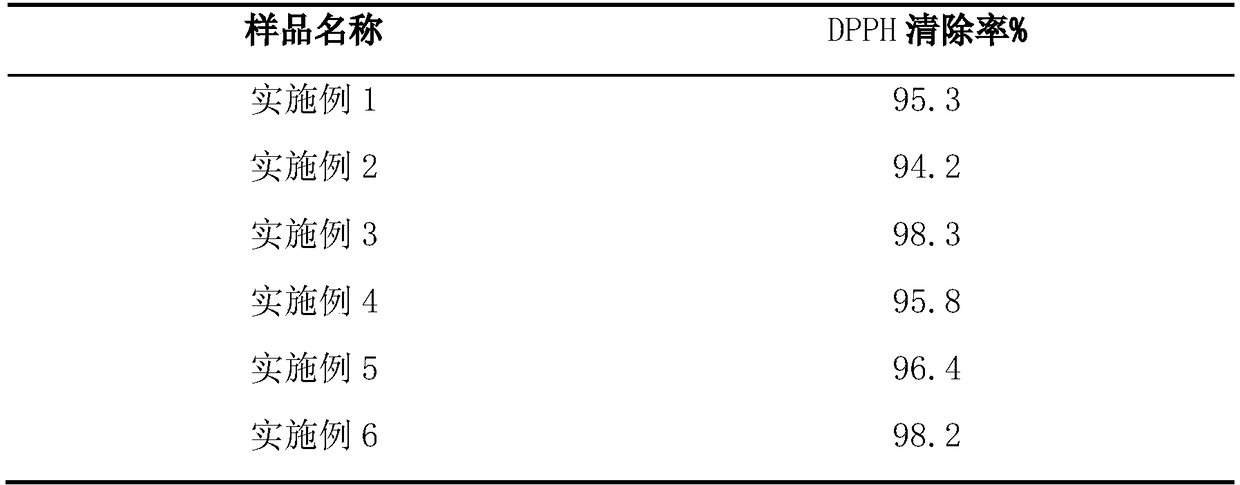

Examples

Embodiment 1

[0021] Grind L-selenium-methylselenocysteine, zinc gluconate, calcium carbonate, powdered sugar, xylitol, mannitol, and magnesium stearate in advance, and pass through a 60-mesh sieve; Base selenocysteine, zinc gluconate, calcium carbonate are mixed according to the mass ratio of 0.001:0.1:5, then add the powdered sugar that mass ratio is 30:5:5: xylitol: mannitol mixes, then add The syrup with a mass ratio of 0.3 is stirred evenly to prepare a soft material (the degree to which the prepared soft material can be held tightly with hands can be formed into agglomerates, and can be cracked by pressing with fingers); the prepared soft material is granulated through a 14-mesh sieve, Then dry it in a vacuum oven at 40°C, control the moisture content at 2%, and then pass through a 18-mesh sieve to remove broken parts. The prepared granules are added with magnesium stearate at a mass ratio of 0.3, fully mixed, and then compressed into chewable tablets on a tablet machine.

Embodiment 2

[0023] Grind L-selenium-methylselenocysteine, zinc gluconate, calcium carbonate, powdered sugar, xylitol, mannitol, and magnesium stearate in advance, and pass through a 60-mesh sieve; Base selenocysteine, zinc gluconate, calcium carbonate are mixed according to the mass ratio of 0.01:1:20, then add the powdered sugar that mass ratio is 80:10:10: xylitol: mannitol mixes, then add The syrup with a mass ratio of 1.5 is stirred evenly to prepare a soft material (the degree to which the prepared soft material can be held tightly with hands can form agglomerates, and can be cracked by pressing with fingers); the prepared soft material is granulated through a 20-mesh sieve, Then dry in a vacuum drying oven at 65°C, the moisture content is controlled at 8%, and then pass through a 24-mesh sieve to remove broken parts. The prepared granules are added with magnesium stearate at a mass ratio of 1, fully mixed, and then compressed into chewable tablets on a tablet machine.

Embodiment 3

[0025] Grind L-selenium-methylselenocysteine, zinc gluconate, calcium carbonate, powdered sugar, xylitol, mannitol, and magnesium stearate in advance, and pass through a 60-mesh sieve; Base selenocysteine, zinc gluconate, calcium carbonate are mixed according to the mass ratio of 0.015:0.5:10, then add the powdered sugar that mass ratio is 50:7.5:7.5: xylitol: mannitol mixes, then add The syrup with a mass ratio of 1.0 is evenly prepared into a soft material (the degree to which the prepared soft material can be held tightly by hand can be formed into agglomerates, and can be cracked by pressing with fingers); the prepared soft material is granulated through a 18-mesh sieve, Then dry in a vacuum oven at 50°C, the moisture content is controlled at 6%, and then pass through a 20-mesh sieve to remove broken parts. The prepared granules are added with magnesium stearate at a mass ratio of 0.6, fully mixed, and then compressed into chewable tablets on a tablet machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com