Preparation method of amphiphilic triblock copolymer modified ultrafiltration membrane with pH-responsive property

A copolymer modification, amphiphilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the irreversible pollution of organic substances such as proteins, insufficient control of membrane pore functionalization, and strong hydrophobicity of separation membranes. and other problems, to achieve the effect of controllable product structure, wide range of applicable monomers, and narrow molecular weight range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

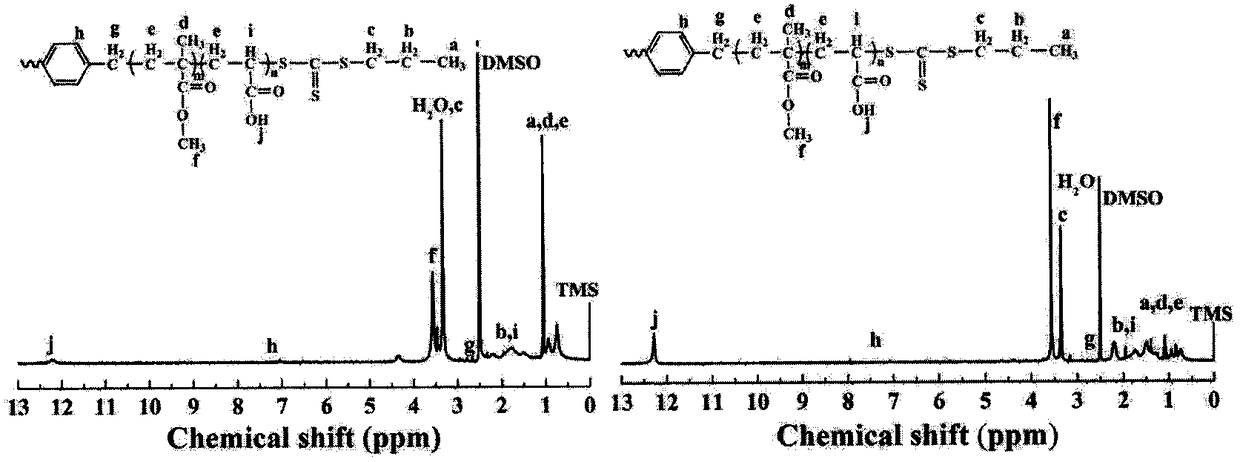

[0025] PVDF / PAA 13 -b-PMMA 80 -b-PAA 13 Membrane preparation

[0026] It uses PAMA as a blending modifier, and prepares a pH-responsive amphiphilic block copolymer modified polyvinylidene fluoride membrane by immersion precipitation phase inversion method, which includes the following steps:

[0027]

[0028] 1. Dissolve refined methyl methacrylate, RAFT reagent and azobisisobutyronitrile in toluene. Use a water pump to evacuate for 30 minutes to remove the air in the reaction solution. Use a double-row tube to repeatedly freeze and thaw three times to remove oxygen, stir and react at 70°C for 24 hours under the protection of argon, remove part of the solvent by rotary evaporation, add the polymer solution to ice n-hexane for precipitation, collect the precipitate, and vacuum-dry to constant weight , to obtain PMMA-RAFT. A certain amount of PMMA-RAFT, acrylic acid and azobisisobutyronitrile were dissolved in 60mL of N,N-dimethylformamide, stirred and reacted at 70°C fo...

Embodiment 2

[0031] PVDF / PAA 83 -b-PMMA 80 -b-PAA 83 Membrane preparation

[0032] Prepare PAA according to Example 1 83 -b-PMMA 80 -b-PAA 83 , specifically control the degree of polymerization of PMMA and PAA according to the molar ratio of methyl methacrylate and acrylic acid input.

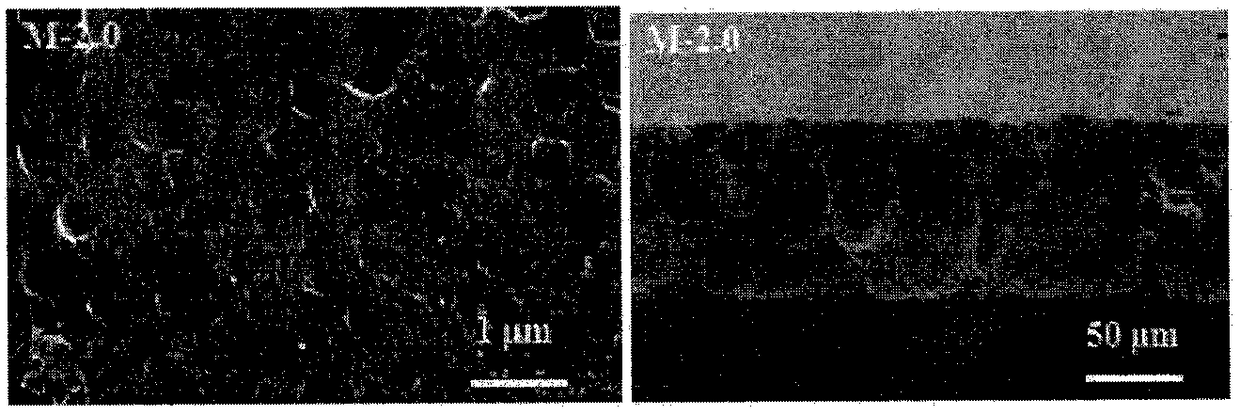

[0033] Weigh 15g PVDF, 7.25g PEG, 1.125g PAA 83 -b-PMMA 80 -b-PAA 83and N,N-dimethylformamide were put into a three-necked flask, fully stirred at 60°C for 12 hours, and dissolved to obtain a homogeneous casting solution, vacuum defoaming, and evenly poured the casting solution into a dry, clean On the glass plate, a 200 μm film was manually scraped out with a scraper, and the glass plate was placed in a coagulation bath in parallel. The coagulation bath was ethanol / water (V / V) 1 / 3, and the temperature was 25°C. The prepared flat membrane was soaked in deionized water for a period of time to remove the solvent, and then freeze-dried to prepare a pH-responsive amphiphilic block copolymer modified po...

Embodiment 3

[0035] PVDF / PAA 83 -b-PMMA 80 -b-PAA 83 Preparation of modified membrane

[0036] Weigh 15g PVDF, 7.25g PEG, 1.125g PAA 83 -b-PMMA 80 -b-PAA 83 and N,N-dimethylformamide were put into a three-necked flask, fully stirred at 60°C for 12 hours, and dissolved to obtain a homogeneous casting solution, vacuum defoaming, and evenly poured the casting solution into a dry, clean On the glass plate, a 200 μm film was manually scraped out with a scraper, and the glass plate was placed in a coagulation water bath in parallel at a temperature of 25°C. After the membrane fell off the glass plate, the modified membrane was taken out from the coagulation bath and immersed in deionized water, and the water was changed twice a day until the solvent was basically replaced, and then freeze-dried to obtain a pH-responsive amphiphilic block copolymer Modified polyvinylidene fluoride film M-4.

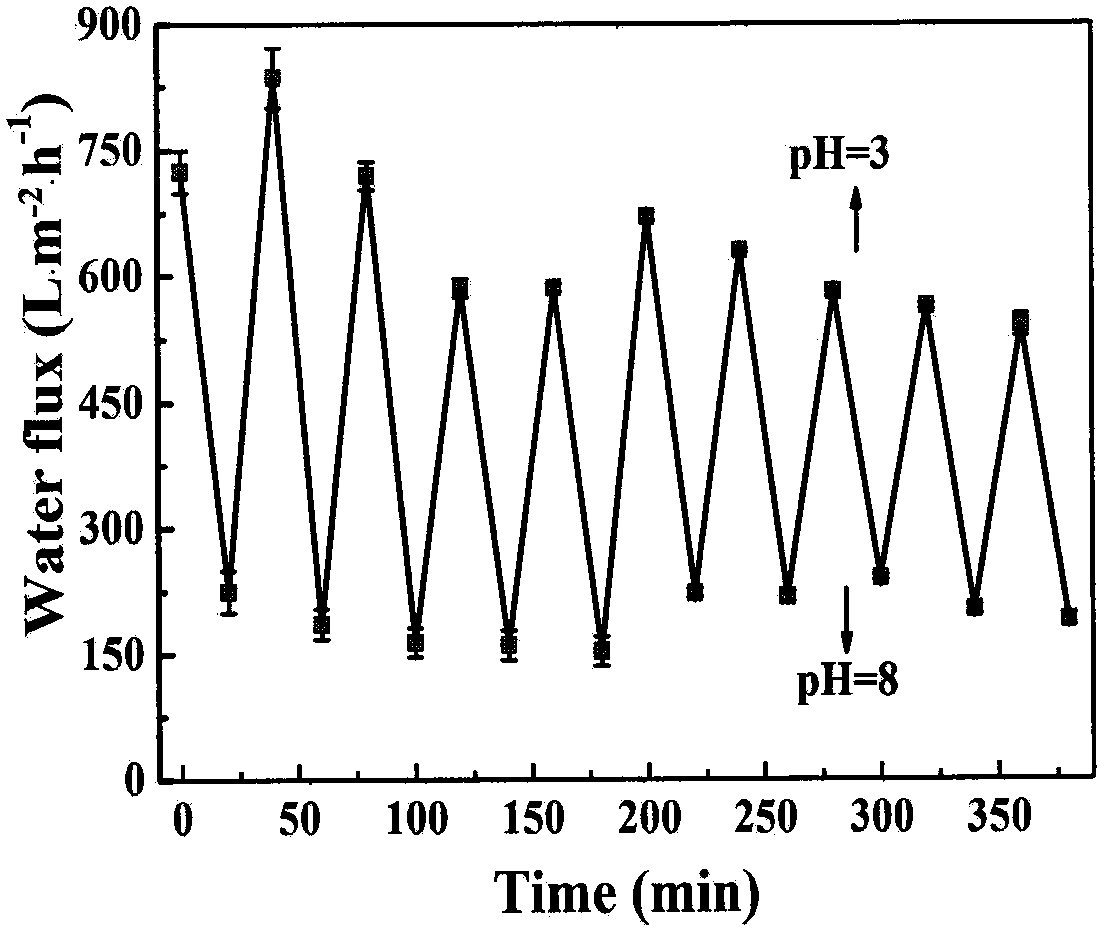

[0037] In order to characterize the pH responsiveness of the modified membrane, the modified membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com