Inorganic ceramic coated functional lithium ion battery diaphragm, preparation method and lithium ion battery thereof

A lithium-ion battery, inorganic ceramic technology, applied in secondary batteries, battery pack parts, secondary battery repair/maintenance, etc., can solve the problem of difficult to control batch consistency of coating thickness, coating equipment and cutting blade wear , The problem of high hardness of alumina material, which is beneficial to the weight energy density, improves heat resistance, and improves heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

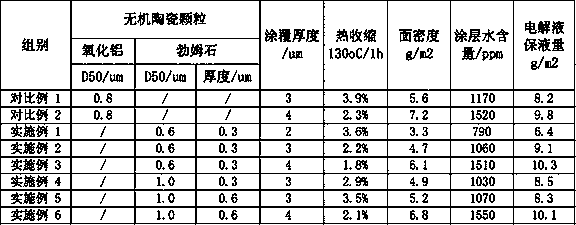

Examples

Embodiment 1

[0041] Preparation of Inorganic Ceramic Coated Functional Lithium-ion Battery Separator Membrane

[0042] The coating slurry formula is based on the weight percentage of the dry material. The coating slurry consists of 3 wt% styrene / acrylate copolymer emulsion, 3wt% lithium polyacrylate, 1 wt% sodium carboxymethyl cellulose, 93 wt% platy boron Mushi particles are composed of four parts. Among them, the average particle size D50 of the platy boehmite particles is 0.6um, D10 is 0.2um, D90 is 2.6um, D99 is 3.7um, and the thickness is 0.3um. Styrene / acrylate copolymer emulsion is selected as the water-emulsion polymer binder, and the contact angle of the water droplet of the dry glue is 125° o . Lithium polyacrylate is selected as the water-soluble polymer binder, and its melting temperature is about 180 o c. During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for about 40 wt% of the total weight of the slurry.

...

Embodiment 2

[0062] The coating slurry formula is based on the weight percentage of the dry material. The coating slurry consists of 10 wt% styrene / acrylate copolymer emulsion, 0.5 wt% lithium polyacrylate, 2 wt% sodium carboxymethyl cellulose, 87.5 wt% platy Boehmite particles consist of four parts. Among them, the average particle size D50 of the platy boehmite particles is 0.6um, D10 is 0.2um, D90 is 2.6um, D99 is 3.7um, and the thickness is 0.3um. Styrene / acrylate copolymer emulsion is selected as the water-emulsion polymer binder, and the contact angle of the water droplet of the dry glue is 125° o . Lithium polyacrylate is selected as the water-soluble polymer binder, and its melting temperature is about 180 o c. During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for about 40 wt% of the total weight of the slurry.

[0063] Using a reverse roll micro-gravure coater, the coating slurry prepared as above is coated on o...

Embodiment 3

[0066]The coating slurry formulation is based on the weight percentage of the dry material. The coating slurry consists of 2 wt% styrene / acrylate copolymer emulsion, 2wt% lithium polyacrylate, 1 wt% sodium carboxymethyl cellulose, 95 wt% platy boron Mushi particles are composed of four parts. Among them, the average particle size D50 of the platy boehmite particles is 0.6um, D10 is 0.2um, D90 is 2.6um, D99 is 3.7um, and the thickness is 0.3um. Styrene / acrylate copolymer emulsion is selected as the water-emulsion polymer binder, and the contact angle of the water droplet of the dry glue is 125° o . Lithium polyacrylate is selected as the water-soluble polymer binder, and its melting temperature is about 180 o c. During the preparation of the slurry, the solvent is deionized water, wherein the weight of the solid part accounts for about 40 wt% of the total weight of the slurry.

[0067] Using a reverse roll micro-gravure coater, the coating slurry prepared as above is coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com