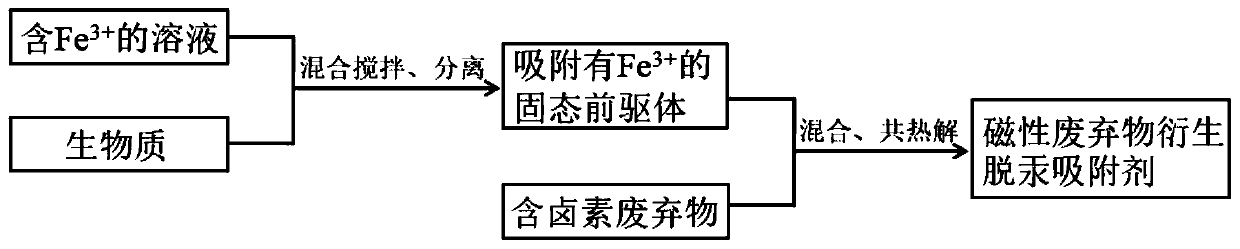

Preparation method, product and application of a magnetic waste-derived mercury removal adsorbent

A waste and adsorbent technology, which is applied in the field of preparation of magnetic waste-derived mercury removal adsorbent, can solve the problems of increasing the operating cost of the power plant, reducing the quality of fly ash, and being unable to recycle, so as to reduce the operating cost of the power plant and increase the Benefits, the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Crush and screen waste wood and waste PVC, select waste wood and waste PVC with a particle size of 100 μm to 200 μm for subsequent use, and configure Fe(NO 3 ) 3 solution, with Fe(NO 3 ) 3 Fe(NO 3 ) 3 The solution was added to the waste wood, and the mixing was continued for 30 minutes.

[0036] Step 2. the mixed solution in step 1 is separated to obtain loaded Fe(NO 3 ) 3 waste wood and will be loaded with Fe(NO 3 ) 3 The discarded wood was put into a drying oven and dried at a constant temperature of 105°C for 12h.

[0037] Step 3. load Fe(NO in step 2 3 ) 3 The waste wood in step 1 is fully mixed with the waste PVC in the ratio of 3:1, and then the mixture is put into the tube furnace, and the flow rate of 200ml / min is passed into N 2 Atmosphere, the tube furnace was heated to 700 °C at a rate of 10 °C / min, and kept at a constant temperature for 30 min, and then heated in N 2 Cooling to room temperature in a medium to obtain a magnetically separab...

Embodiment 2

[0040] Step 1. Crush and screen waste paper and brominated epoxy resin, select waste paper and brominated epoxy resin with a particle size of 150 μm to 250 μm for use, and prepare FeCl with a concentration of 0.09wt.% 3 solution with FeCl 3 The ratio of solution to waste paper is 10ml / g FeCl 3 Add the solution to waste paper, and continue to mix and stir for 30 minutes.

[0041] Step 2. The mixed solution in step 1 is separated to obtain the loaded FeCl 3 of waste paper and will be loaded with FeCl 3 The waste paper was dried in a drying oven at a constant temperature of 105 °C for 12 h.

[0042] Step 3. Load FeCl in step 2 3 The waste paper and the brominated epoxy resin in step 1 are fully mixed at a ratio of 1:1, and then the mixture is put into a tube furnace, and N is introduced at a flow rate of 200ml / min. 2 Atmosphere, the tube furnace was heated to 800 °C at a rate of 10 °C / min, and kept at a constant temperature for 10 min, and then heated in N 2 Cooling to room...

Embodiment 3

[0045] Step 1. crush and screen the waste bamboo and waste PVC, select the waste bamboo and waste PVC with a particle size of 200 μm to 300 μm for subsequent use, and configure Fe(NO 3 ) 3 solution, with Fe(NO 3 ) 3 Fe(NO 3 ) 3 The solution was added to the waste bamboo, and the mixing was continued for 20 minutes.

[0046] Step 2. the mixed solution in step 1 is separated to obtain loaded Fe(NO 3 ) 3 waste bamboo, and will load Fe(NO 3 ) 3 The discarded bamboo was dried in a drying oven at a constant temperature of 120 °C for 12 h.

[0047] Step 3. load Fe(NO in step 2 3 ) 3 The discarded bamboo and the discarded PVC in step 1 are fully mixed at a ratio of 5:1, and then the mixture is put into a tube furnace without any gas (that is, in an air atmosphere), and the tube furnace is heated at 15°C / min The temperature was raised to 500°C at a constant rate, and kept at a constant temperature for 60 minutes, and then in N 2 Cooling to room temperature in a medium to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com