Preparation method of heat conductive silicone rubber slice

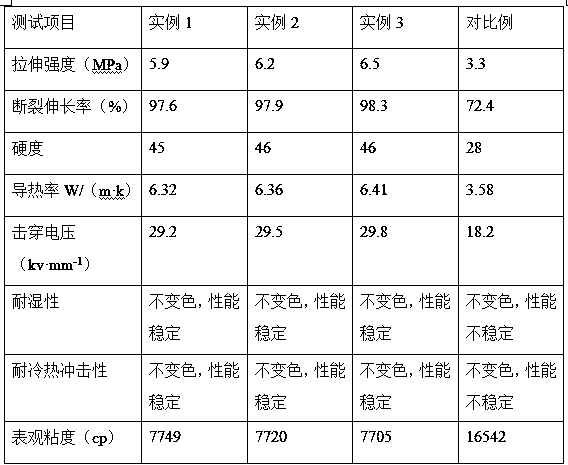

A heat-conducting silica gel sheet, technology of preparation steps, applied in the direction of heat exchange materials, chemical instruments and methods, film/sheet-like adhesives, etc., can solve the problems of easy aging pyrolysis, decreased viscosity, and poor thermal conductivity of heat-conducting silica gel sheets And other problems, to achieve strong adhesion, viscosity will not decrease, excellent bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Take 30-35g of natural flake graphite, put it into a mesh bag, place a titanium metal plate in the mesh bag as an anode, put the mesh bag in a beaker, put a platinum metal plate in the beaker as a cathode, and put a mass fraction of 75 % perchloric acid and glacial acetic acid with a mass fraction of 98% are mixed in a volume ratio of 4:1 to obtain an electrolyte, add 200-300mL of electrolyte to the beaker, control the temperature of the electrolyte in the beaker to 20-22°C, start the power supply, Carry out the electrolysis reaction with a current intensity of 0.3-0.5A. After electrolysis for 40-45 minutes, an expanded graphite acid solution is obtained; add a sodium hydroxide solution with a mass fraction of 40% to the expanded graphite acid solution until the pH of the expanded graphite acid solution is 6.8 to 7.0 to obtain neutralized expanded graphite suspension, put the expanded graphite suspension into a Buchner funnel, wash with water, and filter under reduced pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com