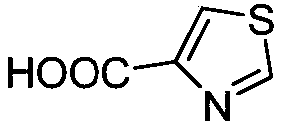

Synthetic method of thiazole-4-formic acid

A synthesis method, the technology of formic acid, applied in the field of electrochemical organic synthesis, can solve the problems of harsh conditions, cumbersome steps, long reaction time, etc., and achieve the effects of easy process control, simple system and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of synthetic method of thiazole-4-carboxylic acid, concrete steps are as follows:

[0024] a. Preparation of electrolyte

[0025] Mix 1mmol (89μL) of 4-bromothiazole with 1mmol (0.1657g) of tetraethylammonium chloride and 0.129mol (10mL) of N,N-dimethylformamide to form an electrolyte, then put titanium as the cathode and magnesium In a one-chamber electrolytic cell with the rod as the anode, 4-bromothiazole, tetraethylammonium chloride and N,N-dimethylformamide are analytically pure, of which: 4-bromothiazole is the substrate, N,N-di Methylformamide is Grade molecular sieve dried solvent, tetraethylammonium chloride as supporting electrolyte.

[0026] b. Electrocarboxylation reaction

[0027] Under normal pressure, carbon dioxide was passed into the above electrolytic cell for 30 minutes, and then at 3mA / cm 2 The constant current density is electrolyzed (the electrolysis process is fed into carbon dioxide until the end of the electrolysis), the...

Embodiment 2

[0032] Embodiment 2 A kind of synthetic method of thiazole-4-carboxylic acid, concrete steps are as follows:

[0033] a. Preparation of electrolyte

[0034] Mix 1mmol (89μL) of 4-bromothiazole with 1mmol (0.2572g) of tetrabutylammonium iodide and 0.129mol (10mL) of N,N-dimethylformamide to form an electrolyte, then put copper as the cathode and magnesium In a one-chamber electrolytic cell with the rod as the anode, 4-bromothiazole, tetrabutylammonium iodide and N,N-dimethylformamide are analytically pure, of which: 4-bromothiazole is the substrate, N,N-di Methylformamide is Grade molecular sieve dried solvent, tetrabutylammonium iodide as supporting electrolyte.

[0035] b. Electrocarboxylation reaction

[0036] Under normal pressure, pass carbon dioxide into the electrolytic cell for 30 minutes, and then use 1mA / cm 2 The constant current density is electrolyzed (the electrolysis process has been passed into carbon dioxide until the end of the electrolysis), the current f...

Embodiment 3

[0041] Embodiment 3 A kind of synthetic method of thiazole-4-carboxylic acid, concrete steps are as follows:

[0042] a. Preparation of electrolyte

[0043] Mix 1mmol (89μL) of 4-bromothiazole with 1mmol (0.2171g) of tetraethylammonium tetrafluoroborate and 0.129mol (10mL) of N,N-dimethylformamide to form an electrolyte, and then put it into the electrolyte with stainless steel as the cathode and In a one-chamber electrolytic cell with a magnesium rod as the anode, 4-bromothiazole, tetraethylammonium tetrafluoroborate and N,N-dimethylformamide are analytically pure, of which: 4-bromothiazole is the substrate, N,N -Dimethylformamide is Grade molecular sieve dried solvent, tetraethylammonium tetrafluoroborate as supporting electrolyte.

[0044] b. Electrocarboxylation reaction

[0045] Under normal pressure, carbon dioxide was passed into the above electrolytic cell for 30 minutes, and then at 9mA / cm 2 The constant current density is electrolyzed (the electrolysis process is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com