A layered inorganic-material organic solvent nanofiltration composite membrane and a preparing method thereof

An organic solvent and inorganic material technology, applied in the field of layered inorganic material organic solvent nanofiltration composite membrane and its preparation, can solve the problems of large distance, hinder smooth molecular penetration, difficult molecular sieving effect, etc., achieve high solvent permeability, The effect of precise solute retention, good operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

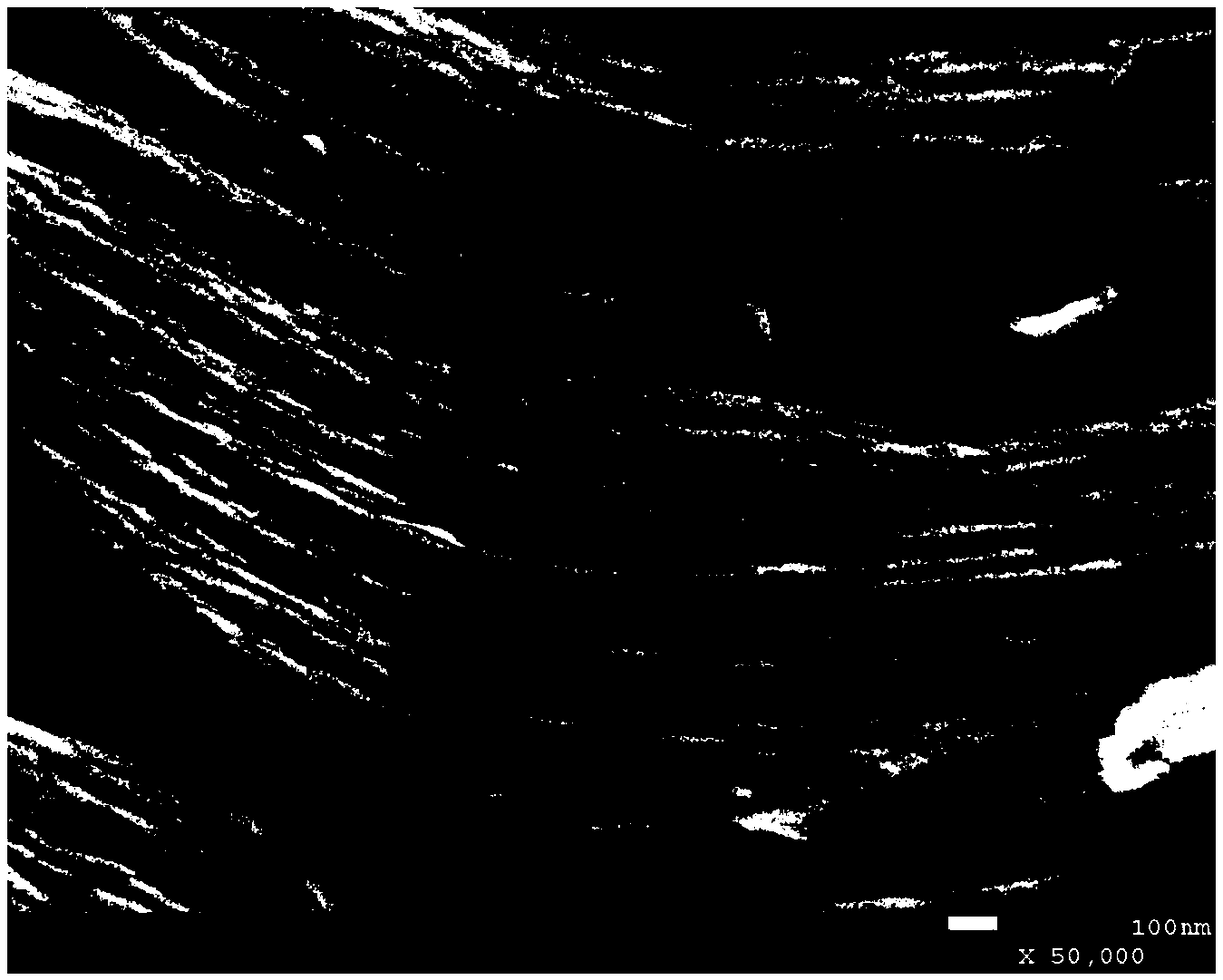

[0030] Preparation of single-walled carbon nanotube aqueous solution: Slowly add single-walled carbon nanotubes (0.01 g) into 120 ml of concentrated sulfuric acid, sonicate in an ultrasonic cleaner for 60 h, take it out and dilute with a large amount of deionized water, and wash with suction and water to nearly neutral, and then dispersed in deionized water at a concentration of 0.001 g / L.

[0031] Use a suction filtration device to vacuum filter 60ml of single-walled carbon nanotube aqueous solution on polydopamine-coated organic microfiltration membrane, control the circulating water pump to carry out the suction filtration pressure not higher than 0.2 bar, and obtain the single-walled carbon nanotube membrane The thickness is 50-80nm.

[0032] The above membranes were tested:

[0033] Solvent flux test results, the flux to acetonitrile is 8179.9 L / m 2 h bar, flux to acetone is 8024.7 L / m 2 h bar, flux to methanol is 5119.4 L / m 2 h bar, the flux to water is 2589.3 L / m...

Embodiment 2

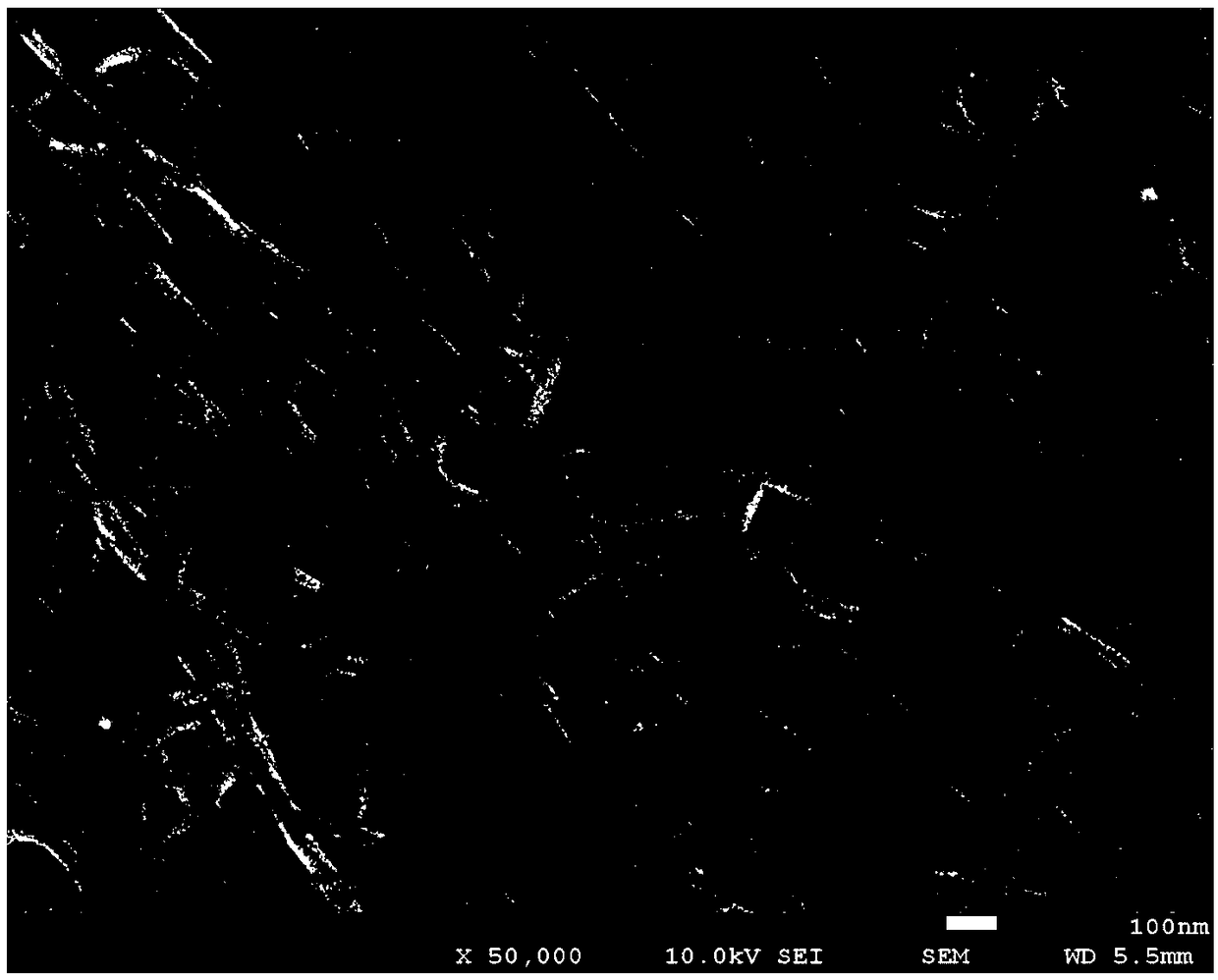

[0038] Ti 3 C 2 T x Preparation of the dispersion: 7.1321 g of titanium hydride, 17.3623 g of titanium carbide, and 4.6916 g of aluminum powder were milled in a ball mill jar for 4 h to make them evenly mixed, and calcined at 1450 °C for 2 h in an argon atmosphere to obtain block Ti 3 AlC 2 . block Ti 3 AlC 2 Milled in a ball mill for 2 h to obtain powdered Ti 3 AlC 2 . Powdered Ti 3 AlC 2 Sieve, mix with hydrofluoric acid according to the ratio of 1g: 16 ml, stir in an oil bath at 60 °C for 72 h, then wash with water, and dry to obtain the etched Ti with three-dimensional structure 3 C 2 T x . Ti 3 C 2 T x and dimethyl sulfoxide according to the ratio of 1 g: 20 ml, stirred at room temperature for 48 h, washed with deionized water after standing, ultrasonicated for 30 min, and centrifuged to obtain the supernatant to obtain the stripped Ti 3 C 2 T x Dispersions.

[0039] The organic microfiltration membrane coated with polydopamine is used as the base memb...

Embodiment 3

[0045] Preparation of single-walled carbon nanotube aqueous solution, Ti 3 C 2 T x The preparation of dispersion liquid is all with embodiment 1.

[0046] Use a suction filtration device to vacuum filter 60ml of single-walled carbon nanotube aqueous solution on polydopamine-coated organic microfiltration membrane, and obtain a single-walled carbon nanotube film with a thickness of 50-80 nm. Continue to vacuum filter Ti 3 C 2 T x dispersion, so that Ti 3 C 2 T x Self-stacking on the surface of the single-wall carbon nanotube film, and finally preparing a multilayer composite film with a thickness of 0.8-1 μm. The multilayer composite film is named CNTs / Ti 3 C 2 T x Composite film. For the above suction filtration, the suction filtration pressure of the circulating water pump is controlled not to be higher than 0.2bar, the same below.

[0047] For CNTs / Ti 3 C 2 T x Composite membranes were tested:

[0048] Solvent flux test results, the flux to acetonitrile is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com