Zero-liquid discharge treatment process for fluorescent penetrant testing wastewater

A fluorescent infiltration and treatment process technology, applied in the field of industrial wastewater treatment, can solve the problems of reverse osmosis concentrated water that cannot meet the discharge requirements, high treatment costs, and zero discharge, and achieve good wastewater treatment effects, low operating costs, and ionization The effect of low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

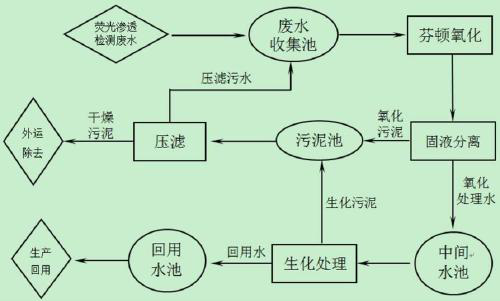

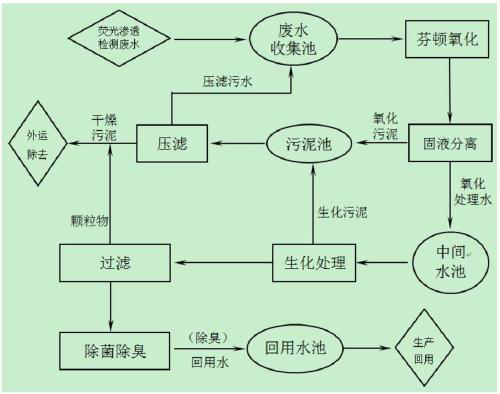

[0041] Such as figure 1 As shown in the schematic flow chart of the zero-liquid discharge treatment process of fluorescent penetrant detection wastewater provided by the present invention, the zero-liquid discharge treatment process of fluorescent permeation detection wastewater includes:

[0042] Centrally recycle the fluorescent penetrant detection wastewater in the workshop and put it into the wastewater collection pool;

[0043] The Fenton oxidation method is used to oxidize and demulsify the wastewater, so that the fluorescent reagents wrapped in organic matter such as low-density mineral oil and surfactant are separated; during Fenton oxidation, sulfuric acid or phosphoric acid is used to control the pH value between 3 and 7. Oxidation reaction time is controlled within 0.5 to 6 hours;

[0044] After Fenton oxidation, use one or more combinations of calcium oxide, calcium hydroxide, calcium carbonate or calcium bicarbonate to neutralize the wastewater, so that the fluores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com