A kind of positive electrode slurry of lithium ion battery and preparation method thereof

A lithium-ion battery and positive electrode slurry technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of uneven dispersion of positive electrode slurry, health hazards of operators, poor processing performance of pole pieces, etc., and achieve good cycle performance , good adhesion, and the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A lithium ion battery cathode slurry, comprising the following raw materials in parts by weight: 86 parts of porous lithium iron phosphate; 2 parts of conductive agent; 4 parts of binder; 2 parts of chitosan; 1-ethyl-3-methylimidazole 2.3 parts of sodium tetrafluoroborate; 32 parts of water; 13 parts of absolute ethanol.

[0044] The conductive agent is composed of graphene, carbon nanotubes and carbon black according to a mass ratio of 1:1.5:0.8;

[0045] The binder is composed of water-based binder LA133, polytetrafluoroethylene and sodium carboxymethylcellulose in a mass ratio of 1:0.6:0.1;

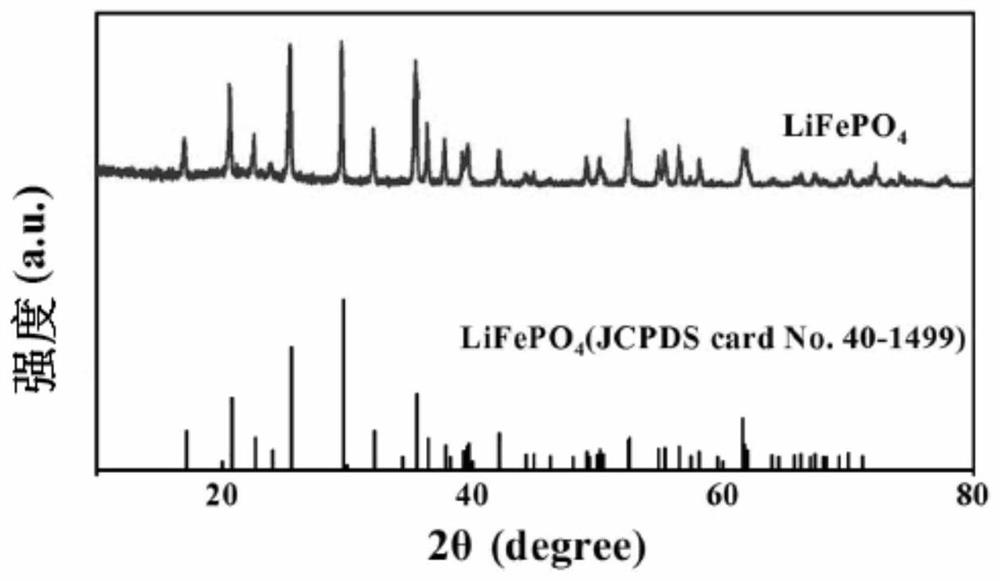

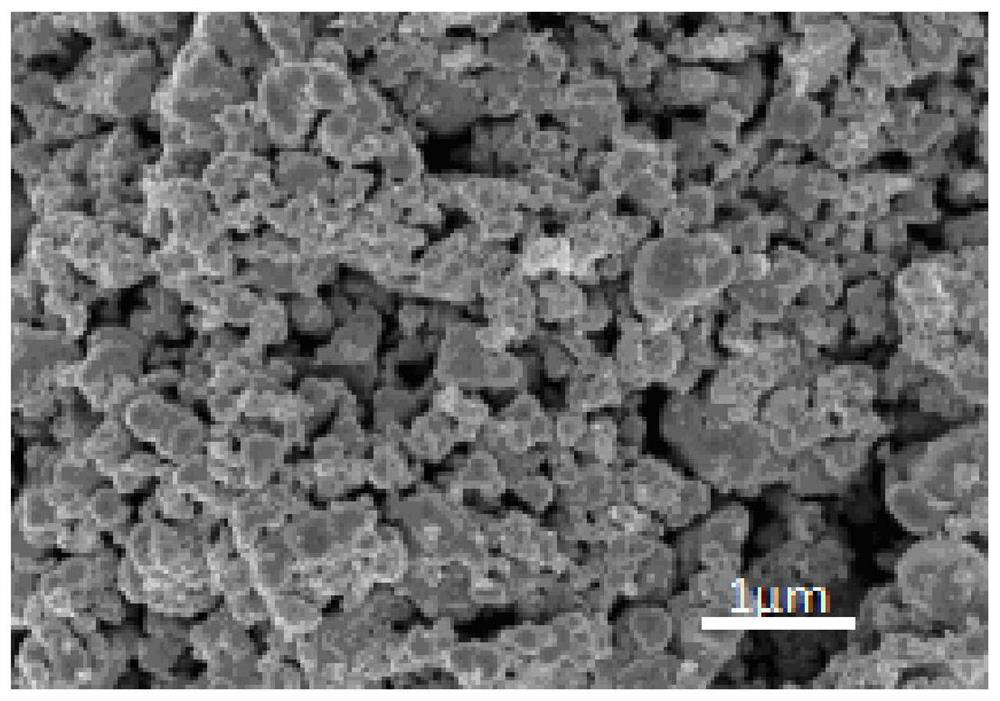

[0046] The preparation method of described porous lithium iron phosphate is:

[0047] S1. Dissolving ferrous phosphate octahydrate and lithium hydroxide in deionized water, adding sodium dodecylbenzenesulfonate and oxalic acid thereto, and adjusting the pH to 4.8 to obtain a mixed precursor solution; the phosphoric acid octahydrate The ratio of the amount of ferrous iron to lith...

Embodiment 2

[0063] A lithium ion battery positive electrode slurry, comprising the following raw materials in parts by weight: 93 parts of porous lithium iron phosphate; 6 parts of conductive agent; 7 parts of binder; 4 parts of chitosan; 1-ethyl-3-methylimidazole 4 parts of sodium tetrafluoroborate; 46 parts of water; 22 parts of absolute ethanol.

[0064] The conductive agent is composed of graphene, carbon nanotubes and carbon black according to a mass ratio of 1:0.8:1.5;

[0065] The binder is composed of water-based binder LA133, polytetrafluoroethylene and sodium carboxymethylcellulose in a mass ratio of 1:0.3:0.3;

[0066] The preparation method of described porous lithium iron phosphate is:

[0067] S1, dissolving ferrous phosphate tetrahydrate and lithium carbonate in deionized water, and adding sodium dodecylsulfonate and ammonium bicarbonate to it, adjusting the pH to 5.0 to obtain a mixed precursor solution; the ferrous phosphate With the ratio of the amount of substance of ...

Embodiment 3

[0075] A lithium ion battery cathode slurry, comprising the following raw materials in parts by weight: 90 parts of porous lithium iron phosphate; 3 parts of conductive agent; 5 parts of binder; 3 parts of chitosan; 1-ethyl-3-methylimidazole 4 parts of sodium tetrafluoroborate; 38 parts of water; 15 parts of absolute ethanol.

[0076] The conductive agent is composed of graphene, carbon nanotubes and carbon black according to a mass ratio of 1:1.0:1.0;

[0077] The binder is composed of water-based binder LA133, polytetrafluoroethylene and sodium carboxymethyl cellulose in a mass ratio of 1:0.5:0.2;

[0078] The preparation method of described porous lithium iron phosphate is:

[0079] S1, dissolving ferrous phosphate octahydrate and lithium dihydrogen phosphate in deionized water, and adding surfactants and additives thereto to adjust the pH to 4.5 to obtain a mixed precursor solution; the ferrous phosphate and lithium source The ratio of the amount of substance is 1:1.2; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com