Praseodymium cobaltate/attapulgite/graphdiyne nanocomposite material, preparation method and application thereof

A nanocomposite material and attapulgite technology, which is applied in the field of praseodymium cobaltate/attapulgite/graphyne nanocomposite materials and its preparation, can solve the problems of limited application prospects, fast electron-hole recombination rate, etc., and achieve improved The effect of denitrification activity, accelerating electron transfer rate and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

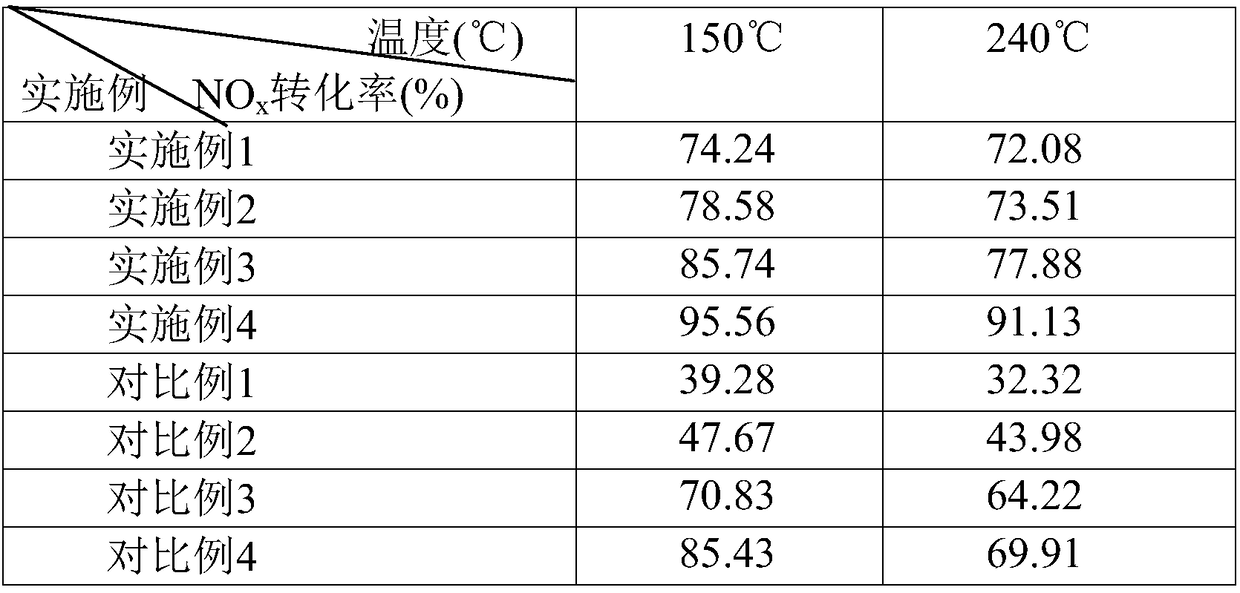

Examples

Embodiment 1

[0023] 1. First, dissolve 29.1000g of hexa[(trimethylsilyl)ethynyl]benzene in 10mL of 1mol / L tetrahydrofuran, add 0.2mL of 1mol / L tetrabutylammonium chloride (TBAF) under nitrogen protection, and The reaction was stirred at ℃ for 8 min, diluted with ethyl acetate, washed three times with saturated brine, dried over anhydrous sodium sulfate, and concentrated to obtain hexaethynylbenzene monomer. Under the protection of nitrogen, dissolve the hexaethynylbenzene monomer with 20mL pyridine, slowly drop into 40mL pyridine and 2cm 2 In the copper foil substrate, the reaction temperature is 60°C, the cross-coupling reaction of hexaethynylbenzene monomer is 48h, and graphyne is formed on the surface of the copper foil;

[0024] 2. Weigh 0.8776g of praseodymium nitrate, 0.5872g of cobalt nitrate, 0.8063g of complexing agent citric acid and 1g of attapulgite into deionized water and stir, and drop 2mL of ethylene glycol, and then transfer it to a water bath, Continue stirring at 70°C, ...

Embodiment 2

[0027] 1. First, dissolve 43.6g of hexa[(trimethylsilyl)ethynyl]benzene in 20mL of 1mol / L tetrahydrofuran, add 0.4mL of 1mol / L tetrabutylammonium chloride (TBAF) under nitrogen protection, and set the temperature at 8°C The reaction was stirred for 10 min, diluted with ethyl acetate, washed three times with saturated brine, dried over anhydrous sodium sulfate, and concentrated to obtain hexaethynylbenzene monomer. Under nitrogen protection, dissolve the hexaethynylbenzene monomer with 30mL pyridine, slowly drop into 50mL pyridine and 4cm 2 In the copper foil substrate, the reaction temperature is 70°C, the cross-coupling reaction of hexaethynylbenzene monomer is 60h, and graphyne is formed on the surface of the copper foil;

[0028] 2. Weigh 0.8776g of praseodymium nitrate, 1.7615g of cobalt nitrate, 1.9230g of complexing agent citric acid and 3g of attapulgite into deionized water and stir, and drop 4mL of ethylene glycol, and then transfer it to a water bath, Continue stirr...

Embodiment 3

[0031] 1. First, dissolve 58.1g of hexa[(trimethylsilyl)ethynyl]benzene in 30mL of 1mol / L tetrahydrofuran, add 0.6mL of 1mol / L tetrabutylammonium chloride (TBAF) under the protection of nitrogen, and set the temperature at 10°C The mixture was stirred and reacted for 12 minutes, diluted with ethyl acetate, washed three times with saturated brine, dried over anhydrous sodium sulfate, and concentrated to obtain hexaethynylbenzene monomer. Under nitrogen protection, dissolve the hexaethynylbenzene monomer with 40mL pyridine, slowly drop into 60mL pyridine and 6cm 2 In the copper foil substrate, the reaction temperature is 80°C, the cross-coupling reaction of hexaethynylbenzene monomer is 72h, and graphyne is formed on the surface of the copper foil;

[0032]2. Weigh 0.8776g of praseodymium nitrate, 2.9358g of cobalt nitrate, 4.3938g of complexing agent citric acid and 5g of attapulgite into deionized water and stir, and add 6mL of ethylene glycol dropwise, then transfer it to a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com