Fast detection method of heavy metal in children textiles and shoes units

A detection method and textile technology, applied in the field of chemical detection, can solve the problems of inaccurate detection results, difficulty in accurate quantification of heavy metals, and cumbersome operations, and achieve the effects of simplifying sample pretreatment steps, accurate and reliable quantitative analysis, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a rapid detection method for heavy metal content in children's textiles, the specific steps are as follows:

[0039] Step 1. Sample pretreatment

[0040] Take children's clothes with printed coating, take the coated part, first use a mixed solvent of n-hexane and acetone (volume ratio 4:1) to clean the oil stain on the surface, wash off the oil-soluble solvent on the cloth with ethanol, and dry it naturally to obtain the desired Process the samples to be tested.

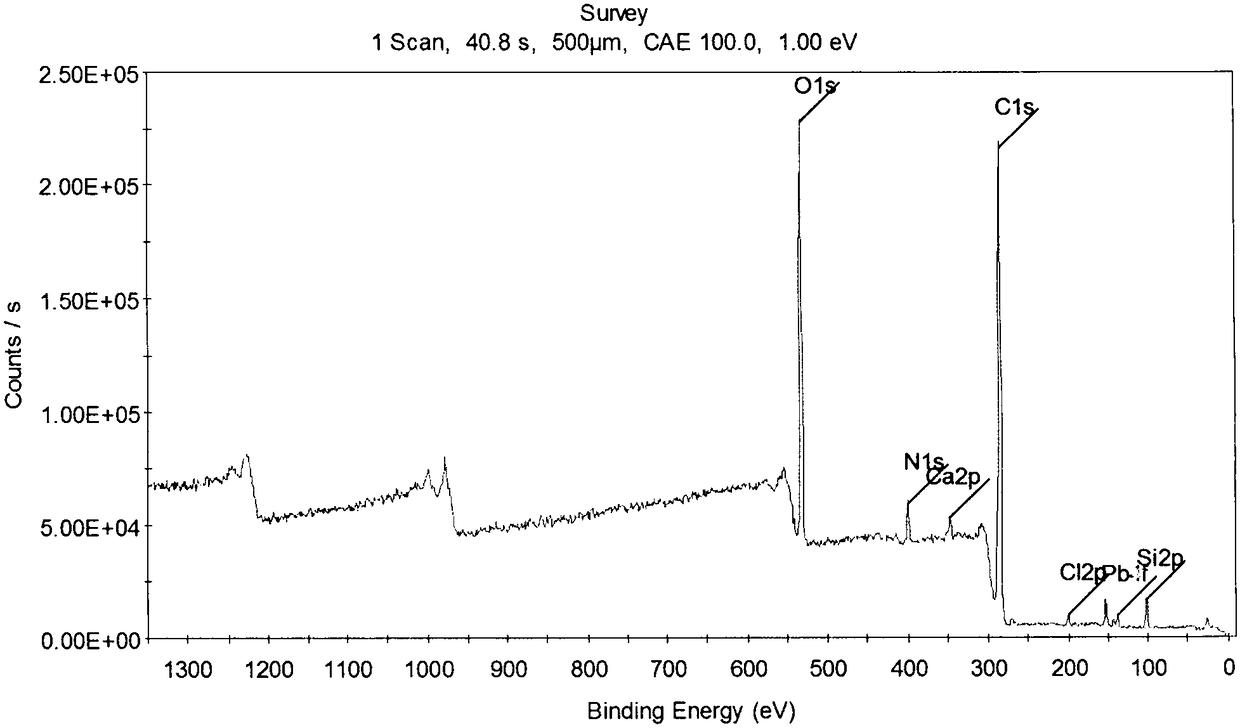

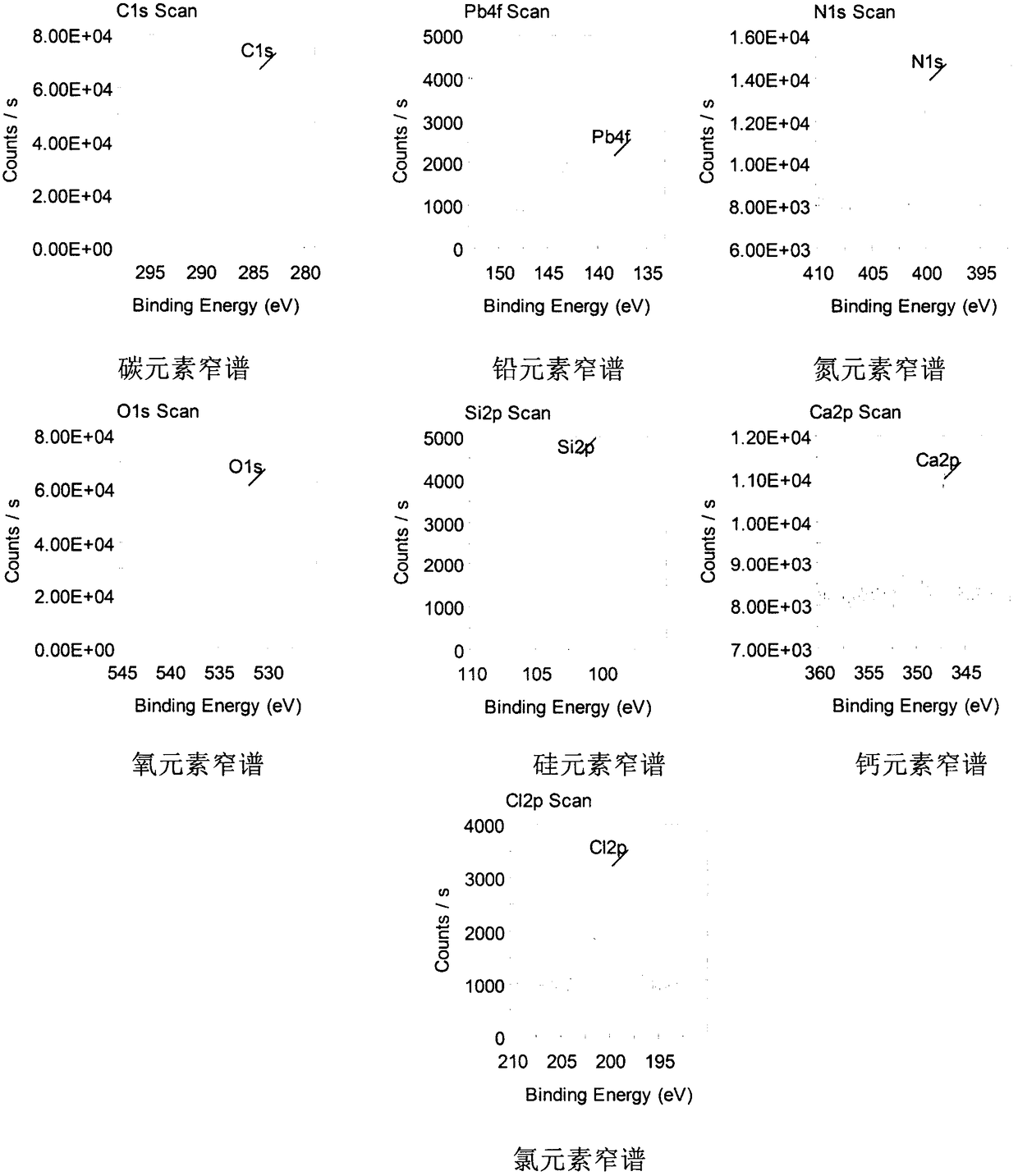

[0041] Step 2, XPS full-spectrum scanning

[0042] X-ray photoelectron spectroscopy, or XPS. Since the characteristic energy values of photoelectron lines and Auger lines of constituent elements are unique, comparing the results of XPS full-spectrum scanning with the binding energies of XPS standard spectrum manuals and databases can be used to identify the elements contained in the sample.

[0043] The test parameters of XPS full-spectrum scanning are set as follows:

[0044] X-...

Embodiment 2

[0063] This embodiment provides a method for rapid detection of medium and heavy metal content in children's shoes, and the specific steps are as follows:

[0064] Step 1. Sample pretreatment

[0065] Take the parts of children's shoes, cut them with a precision plastic slicer, precisely control the thickness of the sample to be tested, and expose the distribution surface, first clean it with a mixed solvent of n-hexane and propanol (volume ratio 4:1), and then wash it with ethanol. The mixed solvent on the shoe parts was washed off, and air-dried to obtain the pretreated sample to be tested.

[0066] In this embodiment, the sample is preferably cut into a thin layer of material with a thickness of 1 mm.

[0067] Step 2-3, XPS full spectrum scan, XPS narrow spectrum scan

[0068] The steps are basically the same as in Example 1.

[0069] From the full-spectrum scanning results, compared with the XPS standard spectrum database, it can be seen that sample 2 contains heavy met...

Embodiment 3

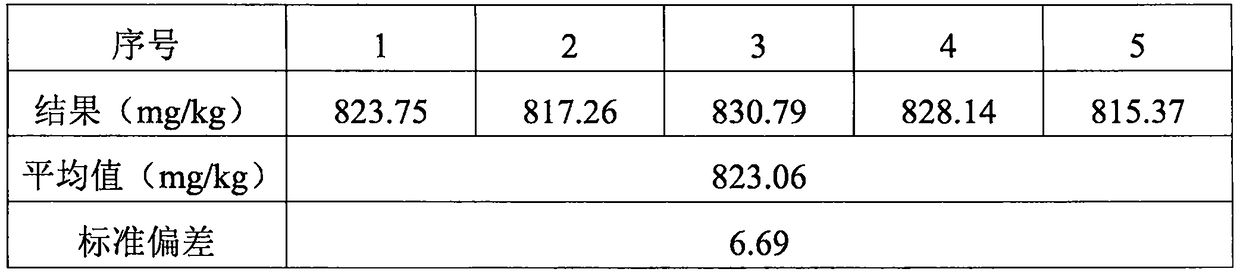

[0085] In this example, according to GB / T 27417-2017 "Guidelines for the Confirmation and Verification of Chemical Analysis Methods for Conformity Assessment", a rapid detection method for heavy metal content in children's textiles and shoe parts provided by the present invention is verified.

[0086] Step 1. Preparation of standard samples

[0087] The heavy metal (lead, cadmium, arsenic) content of 0.01g ~ 9g of solid powder is fully ground and mixed with 10kg of PVC powder, heated and melted, pressed into a sheet structure with a thickness of 0.8 ~ 1.5mm, and the heavy metal (lead , cadmium, arsenic) content of 1mg / kg, 2mg / kg, 3mg / kg, 4mg / kg, 5mg / kg, 10mg / kg, 50mg / kg, 90mg / kg, 100mg / kg, 300mg / kg, 600mg / kg , 900mg / kg series of standard samples.

[0088] Step 2. Determine the detection limit and precision

[0089] According to the methods in 5.4.2.2 and 5.6 of GB / T 27417-2017 "Guidelines for Confirmation and Verification of Chemical Analysis Methods for Conformity Assessmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com