Preparation method and application of citric acid grafted chitosan beads

A technology of chitosan and citric acid, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve unsatisfactory problems and achieve increased adsorption, biodegradability and biological Good compatibility, taking into account the effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

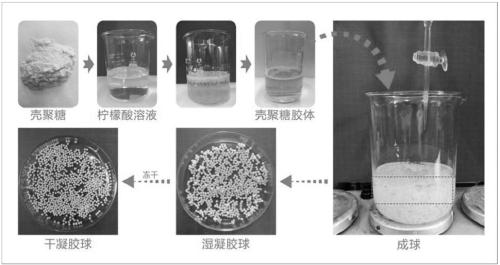

[0034] Embodiment 1: the preparation of citric acid grafted chitosan pellet

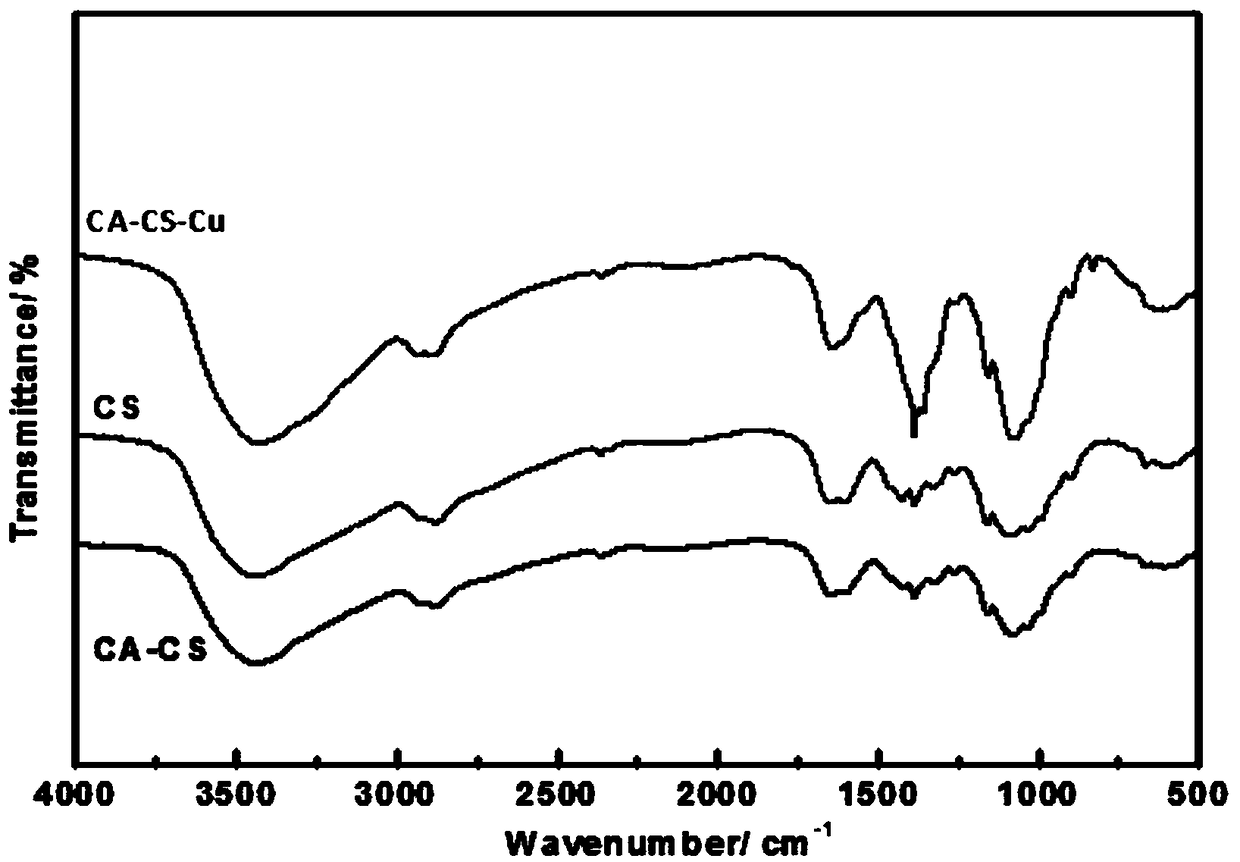

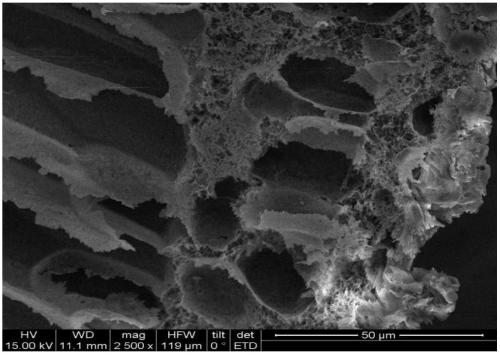

[0035] First, dissolve 18 g of citric acid in 100 mL of distilled water, add 3 g of chitosan (degree of deacetylation ≥ 90.0%, molecular weight 700,000-800,000), and stir for 5 hours at 25 ° C to obtain a uniform and stable chitosan-citric acid gel Then the above gel is poured into a 50mL burette, and dripped dropwise into 400mL of 1mol / L sodium hydroxide solution under magnetic stirring to form a wet gel ball with a particle size of 2.5-3mm; finally the above The formed wet gel balls were vacuum freeze-dried at -80°C for 24 hours to obtain loose and porous citric acid-grafted chitosan pellets. The preparation process of citric acid grafted chitosan pellets is as follows: figure 1 shown. The prepared citric acid-grafted chitosan pellets were detected by infrared spectrometer, and the results were as follows: figure 2 Shown, chitosan (chitosan) at 1658 and 1598cm -1 , while the citric acid grafte...

Embodiment 2

[0037] Embodiment 2: the preparation of citric acid grafted chitosan pellet

[0038] First, dissolve 18 g of citric acid in 100 mL of distilled water, add 3 g of chitosan (degree of deacetylation>90%), and stir for 6 h at 25° C. to obtain a uniform and stable chitosan-citric acid gel; Pour it into a 50mL burette, and drop it dropwise into 400mL of 1mol / L sodium hydroxide solution under magnetic stirring to form wet gel balls with a particle size of 2.5-3mm; finally, the wet gel balls formed above Vacuum freeze-dry at -80°C for 22 hours to obtain loose and porous citric acid-grafted chitosan pellets.

Embodiment 3

[0039] Example 3: Investigation of the influence of different conditions on the adsorption of citric acid-grafted chitosan pellets for copper ions

[0040] Prepare 25mL of copper ion solution with a concentration of 10mg / L, adjust the acidity and alkalinity of the copper solution with hydrochloric acid and / or sodium hydroxide solution to make the pH value 5.4±0.1, and then add 0.2, 0.4, 0.6, 0.8 to the solution respectively , 1.0, 1.2, 1.4, 1.6, 1.8, 2.0g / L chitosan-citric acid pellets, put them into a rotary mixer, the oscillation speed is 160rpm, the temperature is 25±1℃, take out the solution after 24h for measurement The concentration of copper ions was used to calculate the removal rate of copper ions. Under the condition of low concentration of 10mg / L, when the dosage of chitosan pellets is 1g / L, copper ions in water are completely removed.

[0041]Prepare 25mL of copper ion solution with a concentration of 10mg / L, adjust the acidity and alkalinity of the copper solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com