Preparation method of hydrophilic anatase-phase titanium dioxide nano photocatalyst

A nano-photocatalyst and anatase phase technology, applied in the field of photocatalysis, can solve the problems of difficult reuse, low biodegradability, high concentration, etc., and achieve remarkable photocatalytic effect, strong redox ability and good photocatalytic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

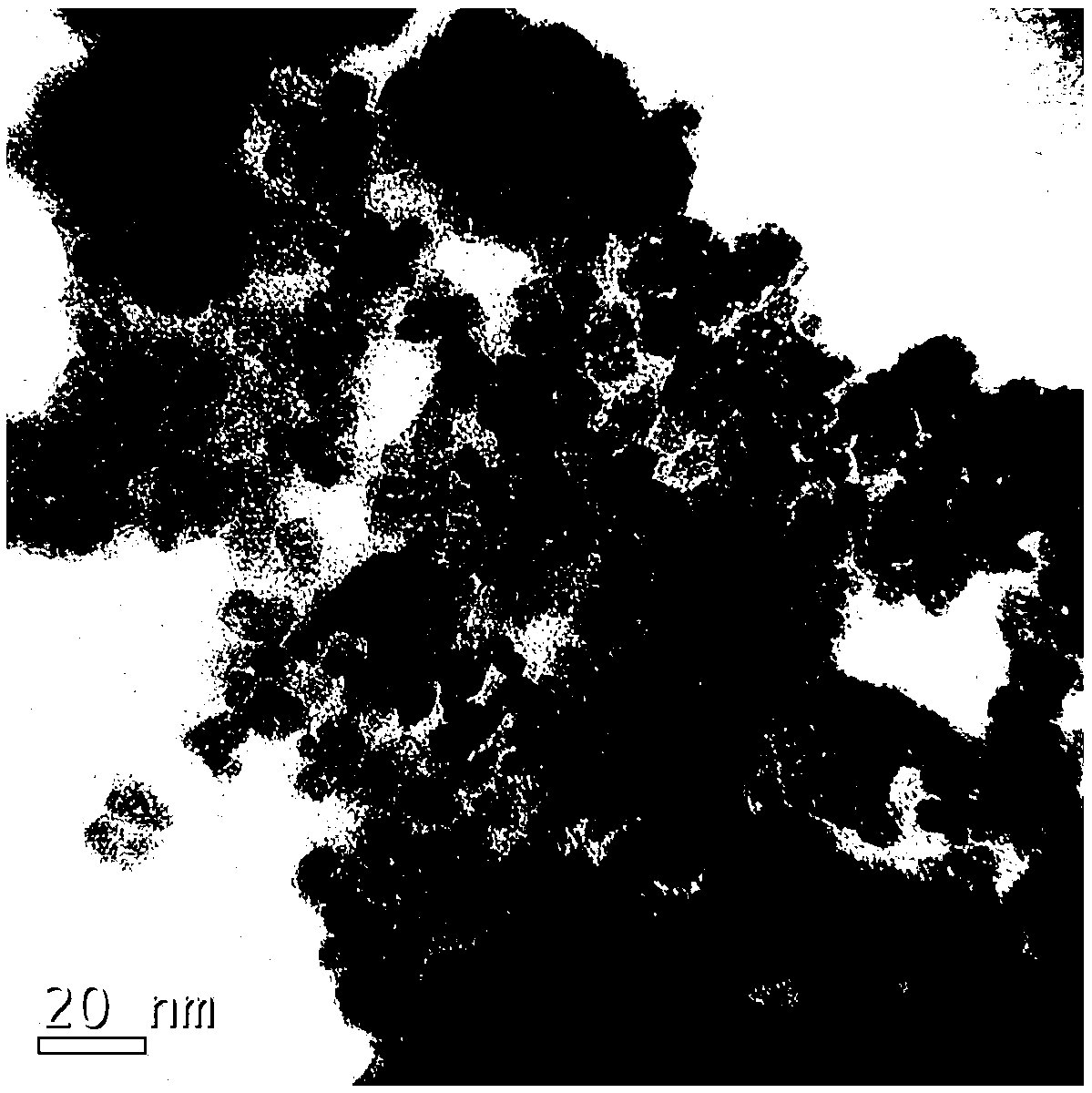

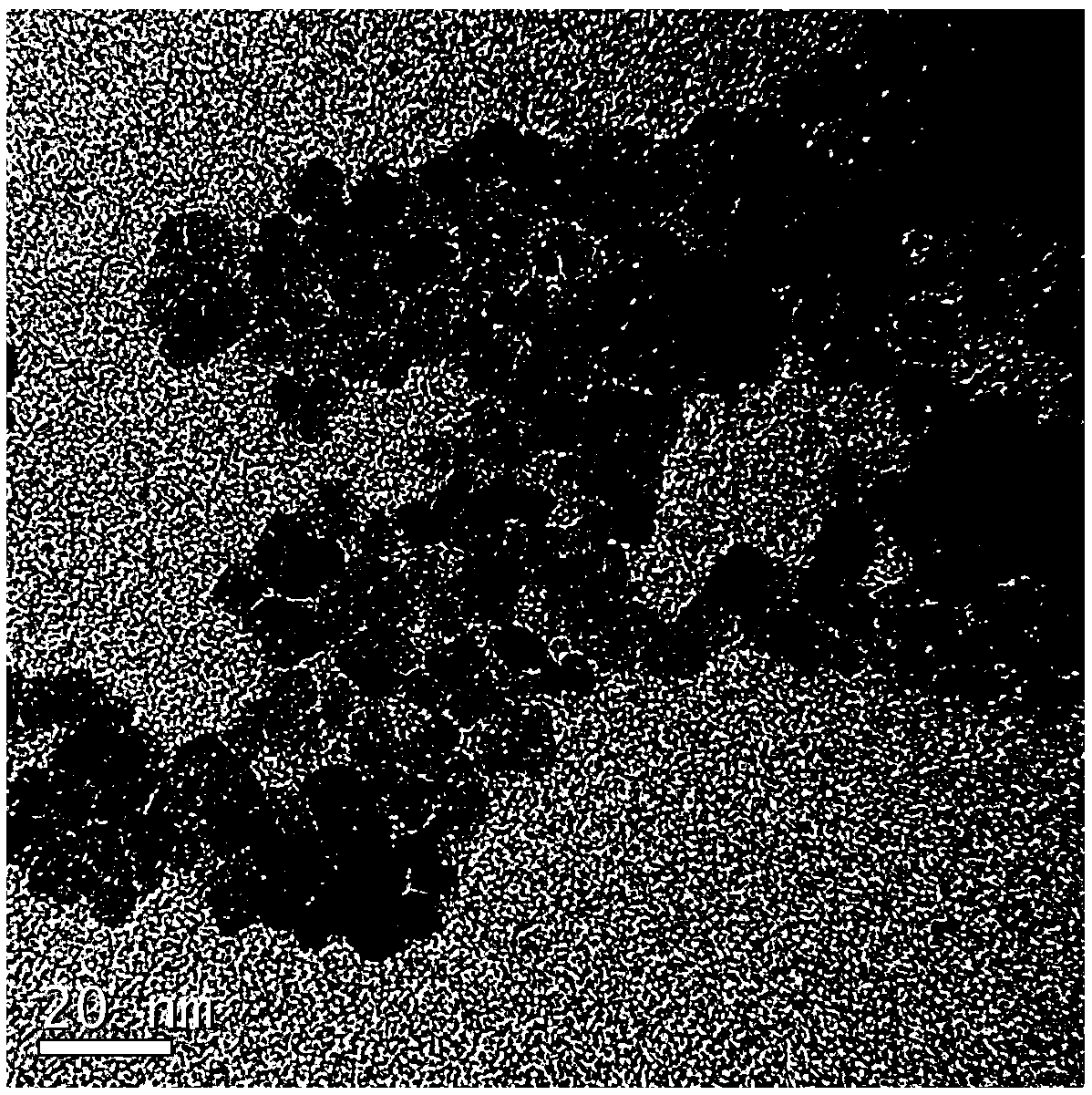

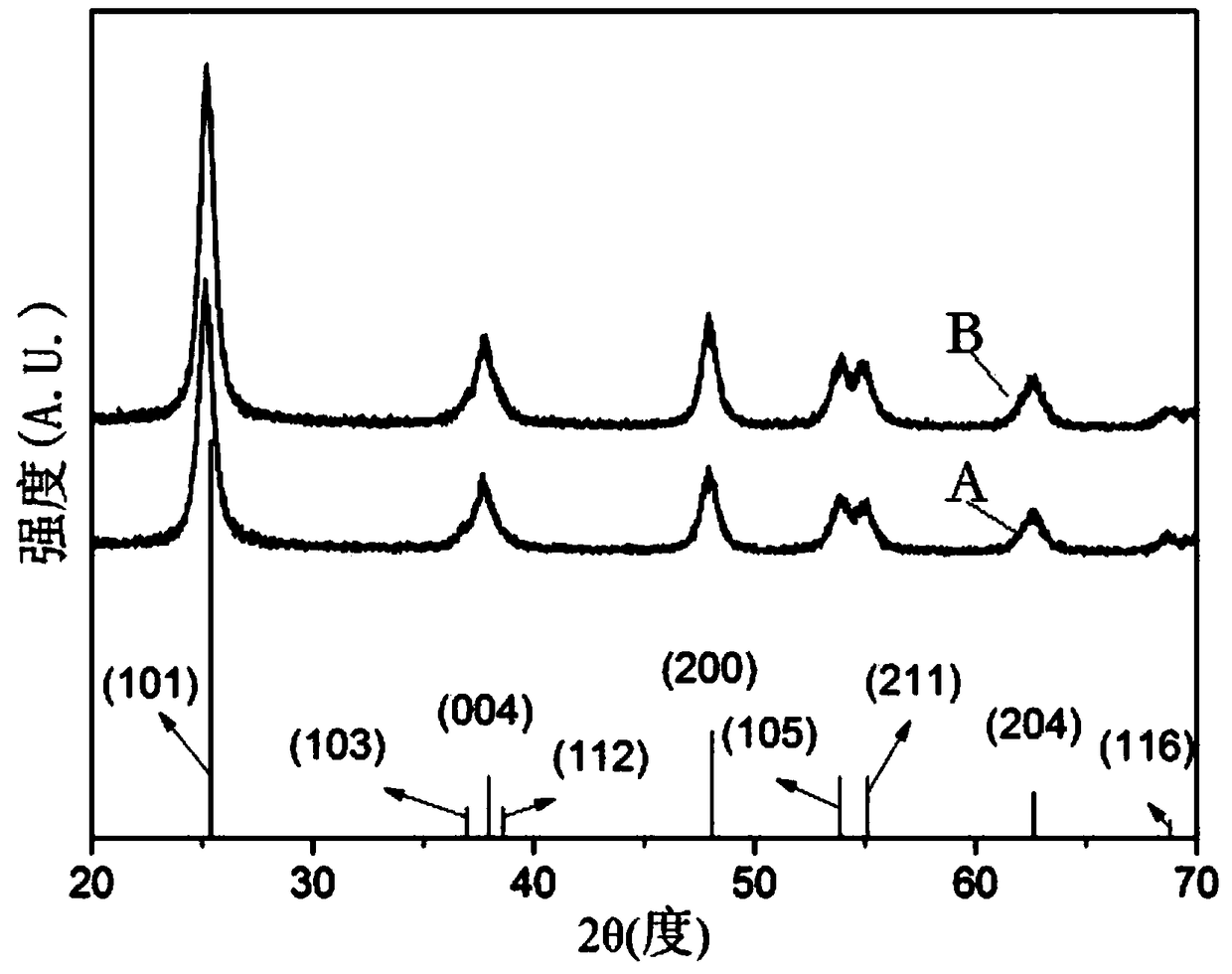

[0030] A kind of preparation method of hydrophilic anatase phase titanium dioxide nano photocatalyst, it comprises the following steps:

[0031] S1. At room temperature, prepare a mixed solution of ethanol and titanium tetrachloride, wherein the molar concentration ratio of ethanol and titanium tetrachloride is 5-50:1. After fully mixing, the mixed solution is placed in an oven at 110°C to Carry out alcohol thermal reaction at 250°C, react for 10h to 25h and then cool to room temperature to obtain a white precipitate with clear liquid in the upper layer;

[0032] S2. Pour off the supernatant of step S1, add ethanol to the white precipitate, centrifuge, and repeat washing for 3 to 5 times to obtain a white precipitate;

[0033] S3, adding deionized water to the white precipitate obtained in step S2, and freeze-drying to obtain a white powdery hydrophilic anatase phase titanium dioxide nano photocatalyst.

[0034] The hydrophilic anatase phase titanium dioxide nanometer photoca...

Embodiment 1

[0036] S1. At room temperature, prepare a mixed solution containing 58.4mL of ethanol and 5.5mL of titanium tetrachloride, mix well and react with alcohol at 130°C for 12h, cool to room temperature, and obtain a white precipitate with clear liquid in the upper layer;

[0037] S2. Pour off the supernatant, add ethanol and centrifuge at 5000rpm for 5min, repeat washing 5 times;

[0038] S3. Pour off the supernatant, add deionized water to fully mix, and freeze-dry for 24 hours to obtain a white powdery hydrophilic anatase phase titanium dioxide nano-photocatalyst.

Embodiment 2

[0040] S1. At room temperature, prepare a mixed solution containing 58.4mL of ethanol and 5.5mL of titanium tetrachloride, mix well, and react with alcohol at 150°C for 12h, cool to room temperature, and obtain a white precipitate with clear liquid in the upper layer;

[0041] S2. Pour off the supernatant, add ethanol and centrifuge at 5000rpm for 5min, repeat washing 5 times;

[0042] S3. Pour off the supernatant, add deionized water to fully mix, and freeze-dry for 24 hours to obtain a white powdery hydrophilic anatase phase titanium dioxide nano-photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com