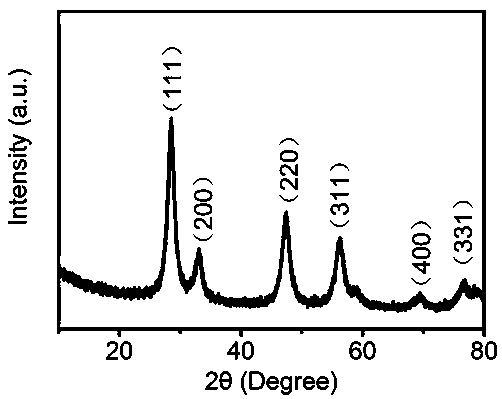

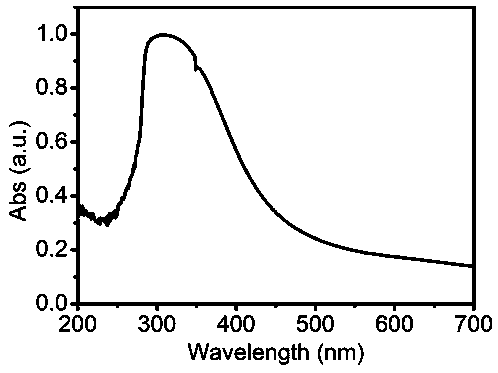

Preparation method and application of high-activity cerium dioxide photocatalyst

A technology of cerium oxide and photocatalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as increasing energy consumption, reduce pollution, Good social and economic benefits, the effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step S1: Add 0.50 g of cerium nitrate into 50 mL of ethanol and stir to dissolve to obtain a homogeneous solution;

[0023] Step S2: Add 1.8 mL of hydrogen peroxide into the homogeneous solution obtained in Step S1, and react at room temperature for 0.5 h to obtain a mixed solution;

[0024] Step S3: adding an aqueous potassium hydroxide solution with a mass concentration of 10% to the mixed solution obtained in step S2, adjusting the pH of the mixed system to 12, continuing to stir and react for 2 hours, centrifuging and washing the precipitate in the reaction solution with deionized water;

[0025] Step S4: drying the precipitate obtained in step S3 at 60° C. for 12 hours to obtain a highly active ceria nanomaterial.

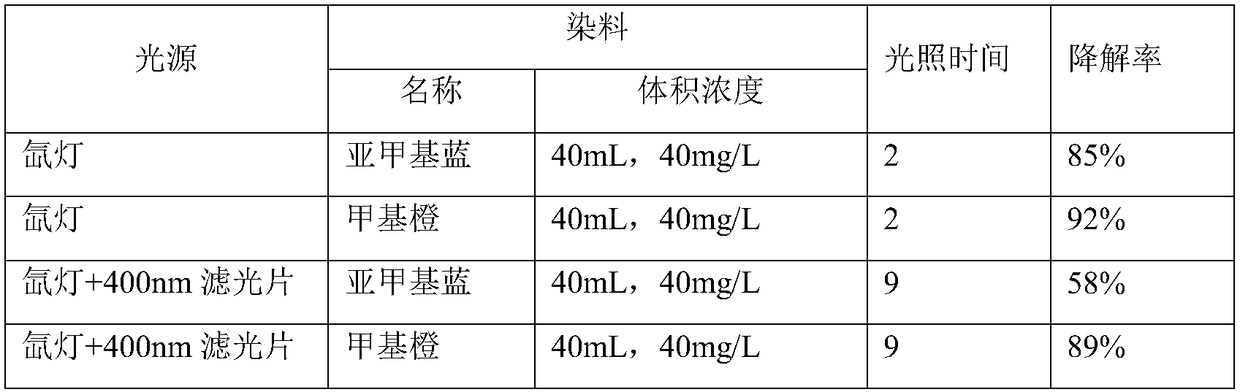

[0026] The photocatalytic activity of the ceria photocatalytic material prepared in this example as a visible light photocatalyst was characterized by photocatalytic degradation of methylene blue and methyl orange solutions. The experimental process is...

Embodiment 2

[0030] Step S1: Add 1.50 g of cerium acetate into 100 mL of ethylene glycol and stir to dissolve to obtain a homogeneous solution;

[0031] Step S2: Add 2 mL of hydrogen peroxide into the homogeneous solution obtained in Step S1, and react at room temperature for 1 hour to obtain a mixed solution;

[0032] Step S3: adding an aqueous sodium carbonate solution with a mass concentration of 10% to the mixed solution obtained in step S2, adjusting the pH of the mixed system to 8, continuing to stir and react for 1 hour, centrifuging the precipitate in the reaction solution and washing it with deionized water;

[0033] Step S4: drying the precipitate obtained in step S3 at 120° C. for 6 hours to obtain a highly active ceria nanomaterial.

[0034] The photocatalytic performance test of the ceria nanomaterial prepared in this example refers to the method in Example 1, and the results are listed in Table 2.

[0035] Table 2

[0036]

Embodiment 3

[0038] Step S1: Add 0.50 g of cerium nitrate into 20 mL of ethylene glycol and stir to dissolve to obtain a homogeneous solution;

[0039] Step S2: Add 0.2 mL of hydrogen peroxide into the homogeneous solution obtained in Step S1, and react at room temperature for 0.5 h to obtain a mixed solution;

[0040] Step S3: adding an aqueous potassium hydroxide solution with a mass concentration of 10% to the mixed solution obtained in step S2, adjusting the pH of the mixed system to 7.5, continuing to stir and react for 2 hours, centrifuging the precipitate in the reaction solution and washing it with deionized water;

[0041] Step S4: drying the precipitate obtained in step S3 at 280° C. for 0.5 h to obtain a highly active ceria nanomaterial.

[0042] The photocatalytic performance test of the ceria nanomaterial prepared in this example refers to the method in Example 1, and the results are listed in Table 3.

[0043] table 3

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com