Catalyst for production of hydrogen from water by photocatalytic decomposition and preparation method of catalyst

A technology for producing hydrogen and catalysts from water, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of high production cost and low catalytic efficiency of catalysts, and achieves low cost and photocatalytic hydrogen production capacity. Strong and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

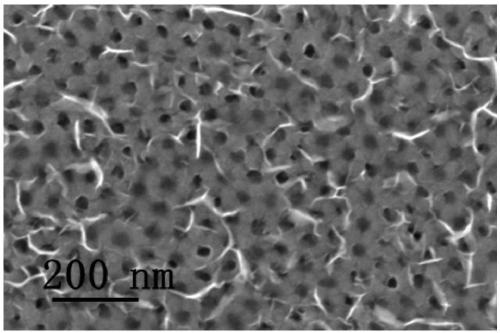

[0046] The present invention also provides a preparation method of the catalyst for photocatalytically decomposing water to produce hydrogen, comprising the following steps:

[0047] The molybdenum disulfide array is grown in-situ in the titanium dioxide nano-pit array, and the reduction stripping is carried out to obtain the obtained product.

[0048] In a preferred embodiment of the present invention, the in-situ growth method includes: depositing a metal molybdenum layer on the titanium dioxide nano-pit array, and performing a sulfidation reaction under the protection of an inert gas.

[0049] In a preferred embodiment of the present invention, the thickness of the metal molybdenum layer is 40-60 nm.

[0050] In a preferred embodiment of the present invention, the method of the vulcanization reaction includes: placing the titanium dioxide nano-pit array deposited with the metal molybdenum layer in a sulfur-containing atmosphere under heating conditions to carry out the vulc...

Embodiment 1

[0056] The preparation method of the catalyst for photocatalytic decomposition of water to produce hydrogen described in this embodiment, the steps are as follows:

[0057] (a) Take a titanium foil with a thickness of 0.05 mm, ultrasonically clean it in acetone, ethanol and deionized water for 30 minutes, and dry it to obtain a clean titanium foil;

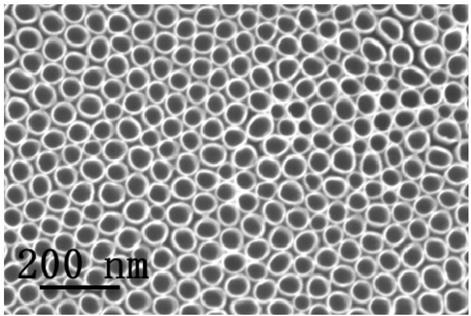

[0058] (b) Immerse the clean titanium foil obtained in step (a) into 3mol / L HF (solute) / H 3 PO 4 (Solvent) In the electrolyte, titanium foil and platinum foil are respectively used as the working electrode and the counter electrode, oxidized at a constant voltage of 10V for 4h, cleaned with ethanol, and dried to obtain a honeycomb-shaped array of titanium dioxide nano-pit arrays arranged in an orderly manner; The scanning electron micrograph of described titania nanopit array is as figure 1 shown;

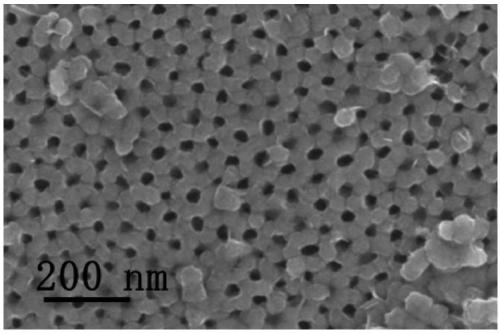

[0059] (c) Depositing a metal molybdenum layer 40nm on the titanium dioxide nano-pit array obtained in step (b) by electron beam e...

Embodiment 2

[0062] The preparation method of the catalyst for photocatalytic decomposition of water to produce hydrogen described in this embodiment, the steps are as follows:

[0063] (a) Take a titanium foil with a thickness of 0.05 mm, ultrasonically clean it in acetone, ethanol and deionized water for 30 minutes, and dry it to obtain a clean titanium foil;

[0064] (b) Immerse the clean titanium foil obtained in step (a) into 3mol / L HF (solute) / H 3 PO 4 (Solvent) In the electrolyte, titanium foil and platinum foil are respectively used as the working electrode and the counter electrode, oxidized at a constant voltage of 10V for 4h, cleaned with ethanol, and dried to obtain a honeycomb-shaped array of titanium dioxide nano-pit arrays arranged in an orderly manner;

[0065] (c) Depositing a metal molybdenum layer of 40 nm on the titanium dioxide nano-pit array obtained in step (b) by electron beam evaporation to obtain a titanium dioxide nano-pit array deposited with a molybdenum layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com