Efficient flocculating agent for papermaking wastewater treatment and preparation method thereof

A technology of papermaking wastewater and flocculant, which is applied in the process of wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. Low dosage, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

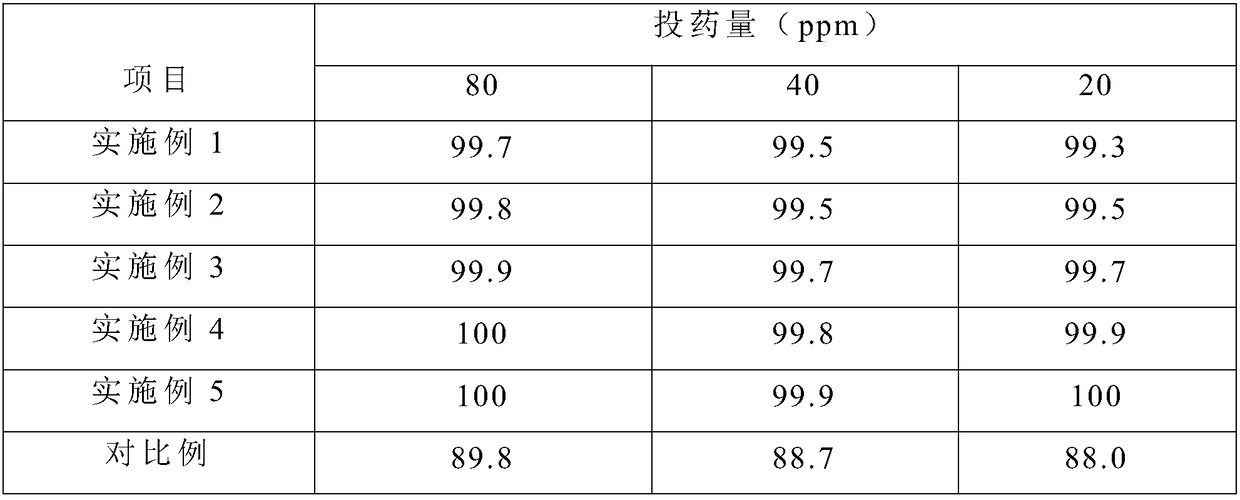

Examples

Embodiment 1

[0028] A preparation method of high-efficiency flocculant for papermaking wastewater treatment, comprising the steps of:

[0029] ⅠDissolve 10g of N-trimethylolacrylamide and 20g of furan-2-methyl-(1-phenyl-3-butenyl)amine in 100g of dimethyl sulfoxide, and add azobisiso 1 g of butyronitrile was stirred and reacted in a nitrogen atmosphere at 65°C for 3 hours, then precipitated in acetone, filtered with suction, and dried in a vacuum oven at 70°C for 10 hours to obtain an acrylamide copolymer;

[0030] II Dissolve 10 g of the acrylamide copolymer prepared in step I and 20 g of bromomethylene (phosphonic acid) in 50 g of tetrahydrofuran, stir and react at 40°C for 6 hours, then remove the tetrahydrofuran by rotary evaporation, and wash the product 3 with ether Next, place the obtained product in a vacuum drying oven at 70°C for 10 hours to obtain an ionic acrylamide copolymer;

[0031] III Add 10 g of the ionic acrylamide copolymer prepared in step II to 100 g of an aqueous so...

Embodiment 2

[0036] A preparation method of high-efficiency flocculant for papermaking wastewater treatment, comprising the steps of:

[0037]ⅠDissolve 10g of N-trimethylolacrylamide and 23g of furan-2-methyl-(1-phenyl-3-butenyl)amine in 110g of N,N-dimethylformamide, and add Add 1.5 g of azobisisoheptanonitrile, stir and react under nitrogen atmosphere at 67°C for 3.5 hours, then precipitate in acetone, filter with suction, and dry the obtained product in a vacuum oven at 72°C for 12 hours to obtain propylene Amide copolymer;

[0038] II Dissolve 10 g of the acrylamide copolymer prepared in step I and 23 g of bromomethylene (phosphonic acid) in 60 g of tetrahydrofuran, stir and react at 45°C for 6.5 hours, then remove the solvent by rotary evaporation, and wash the product 4 with diethyl ether Next, place the obtained product in a vacuum drying oven at 72°C for 12 hours to obtain an ionic acrylamide copolymer;

[0039] III Add 10 g of the ionic acrylamide copolymer prepared in step II t...

Embodiment 3

[0044] A preparation method of high-efficiency flocculant for papermaking wastewater treatment, comprising the steps of:

[0045] ⅠDissolve 10g of N-trimethylolacrylamide and 25g of furan-2-methyl-(1-phenyl-3-butenyl)amine in 13g of N-methylpyrrolidone, and add azobis 2g of isobutyronitrile was stirred and reacted at 69°C in a nitrogen atmosphere for 4 hours, then precipitated in acetone, filtered with suction, and dried in a vacuum oven at 75°C for 13 hours to obtain an acrylamide copolymer;

[0046] II Dissolve 10 g of the acrylamide copolymer prepared in step I and 25 g of bromomethylene (phosphonic acid) in 65 g of tetrahydrofuran, stir and react at 50°C for 7 hours, then remove the solvent by rotary evaporation, and wash the product 5 with diethyl ether The second time, the obtained product was placed in a vacuum drying oven at 75°C for 13 hours to obtain an ionic acrylamide copolymer;

[0047] III Add 10 g of the ionic acrylamide copolymer prepared in step II to 160 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com