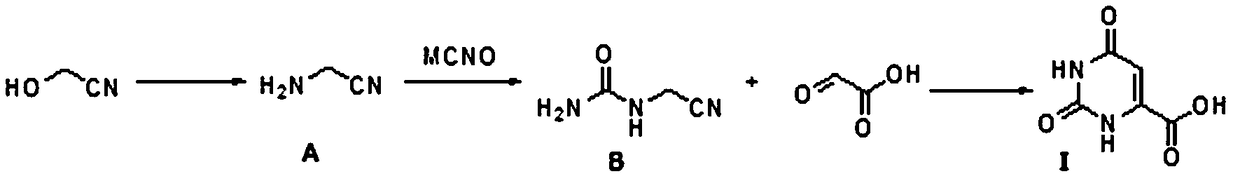

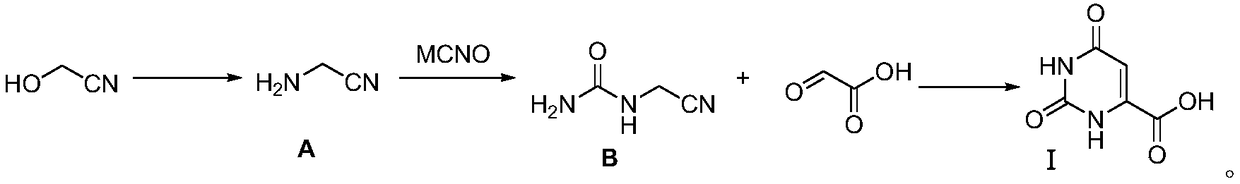

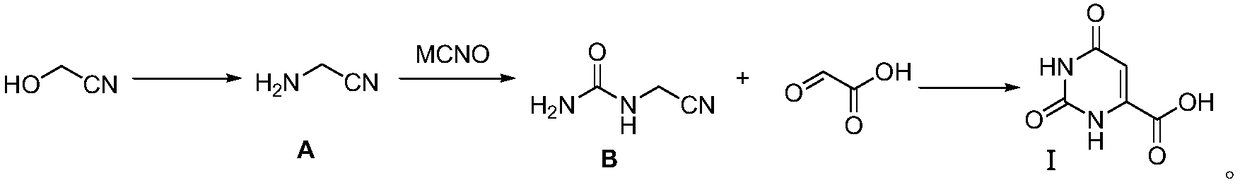

New synthesis method of orotic acid

An orotic acid and new method technology, applied in the direction of organic chemistry, can solve the problems of non-compliance with environmental protection requirements, use of dangerous reagents, and high cost of raw materials, and achieve the effects of avoiding by-products, less environmental pollution, and short process routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] S1: Add 300 kg of 10% industrial concentrated ammonia water to a 1000-liter reactor, turn on the circulating refrigerant, lower the temperature of the reaction liquid to about 0°C, and slowly drop 66 kg of 50% hydroxyacetonitrile solution into the reaction liquid while stirring; After the dropwise addition, keep the internal temperature at 0-10°C and continue to stir for 4 hours to stop the reaction; remove the freezing liquid, turn on the circulating water, turn on the vacuum, raise the temperature to 40-50°C, and remove the excess ammonia gas in the reaction system to obtain the reaction system a;

[0037] S2: Use concentrated hydrochloric acid to adjust the pH of the reaction system a to 5-6, add 180 kg of 25% sodium cyanate solution dropwise, and keep the pH of the system unchanged. After the addition, the temperature is raised to 80°C for 5 hours, and the reaction is completed by spotting. Obtain reaction system b;

[0038] S3: Pump 102 kg of 50% glyoxylic acid in...

Embodiment 2

[0041] S1: Add 320 kg of 10% industrial concentrated ammonia water to a 1000-liter reactor, turn on the circulating refrigeration liquid, lower the temperature of the reaction liquid to about 0°C, and slowly add 68 kg of fresh 50% hydroxyacetonitrile solution to the reaction liquid under stirring In the process, after the dropwise addition is completed, keep the internal temperature at 0-10°C and continue stirring for 4 hours, then stop the reaction. Remove the freezing liquid, turn on the circulating water, turn on the vacuum, raise the temperature to 40-50°C, and pump out the excess ammonia gas in the reaction system to obtain the reaction system a;

[0042] S2: Use concentrated hydrochloric acid to adjust the pH of the reaction system a to 5-6, add 190 kg of 25% sodium cyanate solution dropwise, keep the pH of the system constant while adding dropwise, raise the temperature to 80°C for 5 hours after the dropwise addition, and spot the plate for detection After the reaction ...

Embodiment 3

[0046]S1: Add 350 kg of 10% industrial concentrated ammonia water to a 1000-liter reactor, turn on the circulating refrigeration liquid, lower the temperature of the reaction liquid to about 0°C, slowly add 72 kg of 50% hydroxyacetonitrile solution to the reaction liquid dropwise under stirring, After the dropwise addition is completed, keep the internal temperature at 0-10°C and continue to stir the reaction for 4 hours, stop the reaction, remove the freezing liquid, turn on the circulating water, turn on the vacuum, raise the temperature to 40-50°C, pump out the excess ammonia gas in the reaction system, use the waste gas The absorption tower is sprayed and absorbed, and recovered for use;

[0047] S2: Use concentrated hydrochloric acid to adjust the pH of the reaction solution to 5-6, add 200 kg of 25% sodium cyanate solution dropwise, keep the pH of the system constant while adding dropwise, raise the temperature to 80°C for 5 hours after the addition, and spot the plate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com