Preparation method of fluorescent cholesteric cellulose nanocrystal film with acid-base gas response

A nanocrystal and gas-responsive technology, applied in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost and complicated sensor operation, and achieve the effect of avoiding agglomeration, avoiding aggregation and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a fluorescent cholesteric cellulose nanocrystal film with acid-base gas response:

[0037] 1) Preparation of CNC suspension: Add 10g of WhatmanCF11 cellulose powder and 175mL of 64w% sulfuric acid solution into a round-bottomed flask, stir for 1 hour at 45°C, and add 1L of deionized water to terminate the reaction. After standing for 1 day, pour off the supernatant, centrifuge the lower turbid solution at 10,000rpm for several times and collect the upper turbid solution, and then place 4 Carry out dialysis treatment in the dialysis bag, to remove unnecessary free acid in the suspension, dialysis 15 days until the CNC suspension is neutral, stand-by;

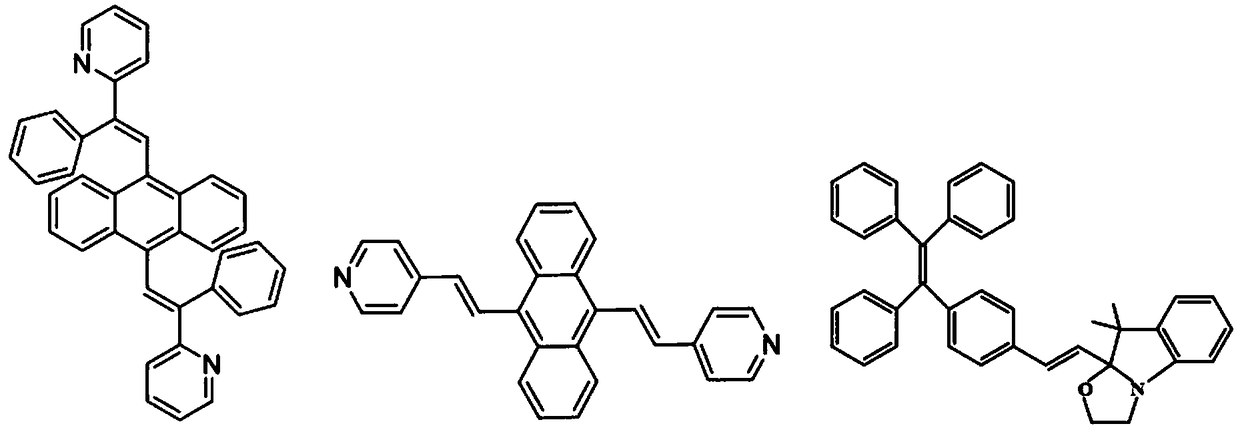

[0038] 2) Preparation of BPP2VA: add anthracene (38.0mmol), paraformaldehyde (200.0mmol), zinc chloride (51.4mmol) and 1,4-dioxane (80.0ml) into a single-necked round bottom flask in sequence according to the determined ratio Add a certain amount of concentrated hydrochloric acid dropwise, and reflu...

Embodiment 2

[0050] This example is the same as Example 1, except that the AIE organic small molecule fluorescent materials used can also be spiropyran or spirooxazine compounds that respond to acid and alkaline gases, including BP4VA, TPE- OX et al.

Embodiment 3

[0052] This embodiment is the same as Embodiment 1, except that the acid gas used can also be volatile acids such as nitric acid, formic acid, acetic acid, trifluoroacetic acid and hydrobromic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com