Bacillus flexus alkaAU as well as method, product, and application for producing uric acid oxidase

A technology of Campylobacter and uric acid oxidase, applied in the field of microorganisms, can solve the problems of high price, high production cost, low enzyme activity, etc., and achieve the effect of wide application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

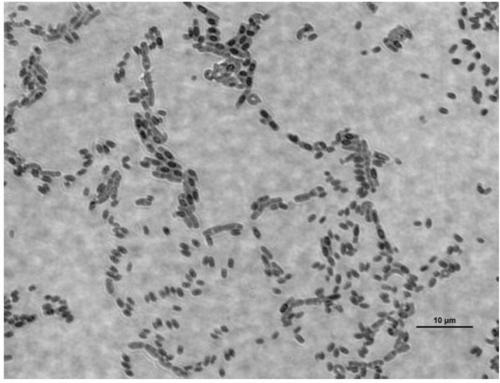

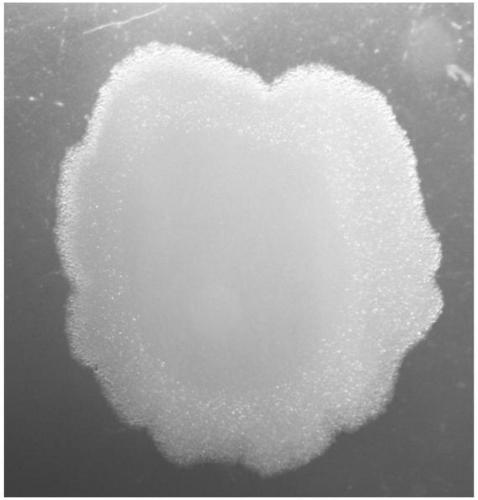

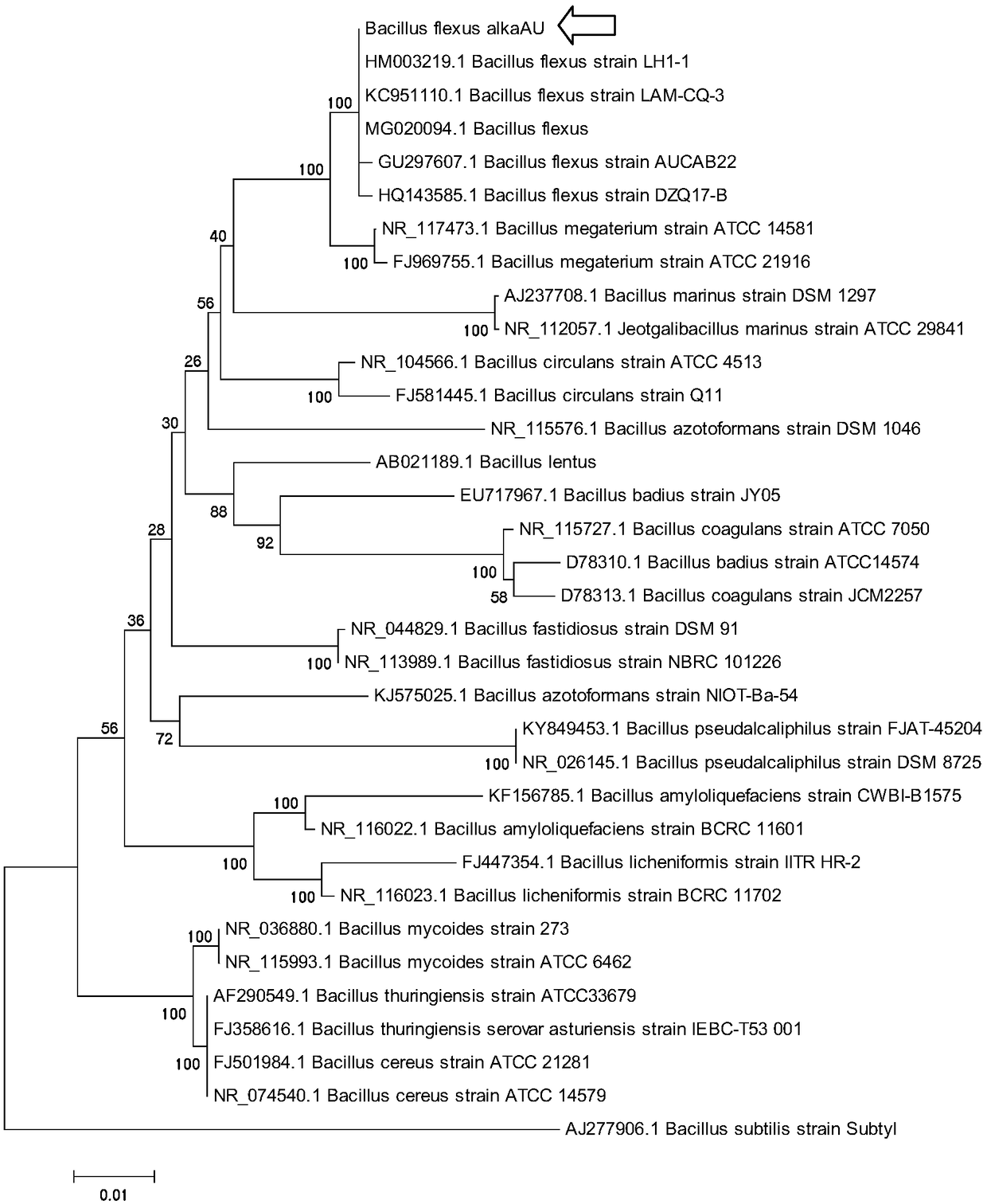

[0032] Example 1, a Bacillus flexus alkaAU, its biological deposit number is CCTCC NO: M 2018378. The isolation of Bacillus flexus alkaAU, the steps are as follows:

[0033]In the low-tide area of Tianwan Nuclear Power Station in Lianyungang, 10g of sea mud was excavated at 5cm below the ground, and added into a triangular flask filled with 90mL of sterile water under aseptic operation, and oscillated for 30min to fully disperse the sample. Pipette 1.0 mL for gradient dilution, select an appropriate dilution and spread it on a screening medium plate, incubate at 37°C for 36 hours, and select colonies with transparent circles. The colony was picked and inoculated into the enzyme-producing medium, cultured at 37°C for 36 hours, and the culture was centrifuged at 5000rpm for 10 minutes to obtain the supernatant, and the urate oxidase activity in it was detected. Prepare 0.3mmol / L uric acid solution with 0.2mol / L boric acid buffer solution (pH 8) as the substrate solution. Set...

Embodiment 2

[0056] Embodiment 2, the method for producing urate oxidase by Bacillus flexus alkaAU described in embodiment 1, the steps are as follows:

[0057] The seed solution was prepared according to the method in Example 1. The seed solution (10 7 cells / mL) were inoculated in the enzyme-producing medium at a 1% (v / v) inoculum size. 180rpm, liquid volume 20%, culture at 37°C for 72h, centrifuge or filter the cells, collect the supernatant, and obtain the uric acid oxidase fermentation broth. According to the method in embodiment example 1, the enzyme activity of the fermented broth was determined to be 0.52U / mL. The amount of enzyme needed to convert 1 μmol of uric acid per minute is 1 enzyme activity unit.

[0058] Enzyme production medium: prepared with 0.5% yeast powder, 1% fish peptone, 0.5% uric acid, and 0.5mol / L phosphate buffer (pH6).

[0059] Properties of urate oxidase produced by Bacillus flexus alkaAU:

[0060] (1) Effect of reaction temperature on enzyme activity:

...

Embodiment 3

[0066] Example 3, using Bacillus flexus alkaAU to hydrolyze pullulan, the steps are as follows:

[0067] Add pullulan with a final concentration of 1% to beef extract peptone medium, and inoculate Bacillus alkaAU. 180rpm, 20% solution volume, culture at 37°C for 72h, centrifuge the cells, collect the supernatant, dialyze with 0.01mol / L phosphate buffer (pH7) at 4°C to remove reducing sugars, and obtain the pullulanase extract. Take 100 μL of enzyme extract, add 100 μL of phosphate buffer pH 7, then add 100 μL of 1% pullulan solution (prepared in pH 7 phosphate buffer) and mix well, and react at 37°C for 30 min; at the same time, as a negative control group, take enzyme extract 100 μL, add 100 μL of phosphate buffer pH 7, then bath in boiling water for 10 minutes, then add the substrate, the reaction conditions are the same as above; after the reaction, add 100 μL of DNS to both groups, and bath in boiling water for 10 minutes. The absorbance at 540 nm of the reaction solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap