Ultrathin-film composite membrane based on thermally rearranged poly(benzoxazole-imide) copolymer, and production method therefor

A technology of benzoxazole and thermal rearrangement polymerization, which is applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve problems such as unconsidered and undisclosed organic solvent separation performance, and achieves high power density, excellent thermal Stability, effect of excellent organic solvent nanofiltration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0124] [Synthesis Example 1] Synthesis of hydroxyl-containing polyimide-polyimide copolymer

[0125] Dissolve 5.0mmol of 3,3'-diamino-4,4'-dihydroxybiphenyl (HAB) and 5.0mmol of 4,4'-diaminodiphenyl ether (ODA) in 10mL of anhydrous NMP and cool to 0° C., and then 10.0 mmol of 4,4′-oxydiphthalic anhydride (ODPA) dissolved in 10 mL of anhydrous NMP was added. After stirring the reaction mixture at 0° C. for 15 min, the temperature was raised to room temperature and left overnight to obtain a polyamic acid viscous solution. Next, 20 mL of ortho-xylene (ortho-xylene) was added to the polyamic acid solution, followed by vigorous stirring and heating, and imidization at 180° C. for 6 h. During this process, the water liberated by the formation of imide rings was separated as an azeotropic mixture of xylenes. The brown solution thus obtained was cooled to room temperature, precipitated in distilled water, washed several times with warm water, and dried in a convection oven at 120° ...

Embodiment 1

[0136] [Example 1] Preparation of thermally rearranged poly(benzoxazole-imide) copolymer support (electrospun membrane)

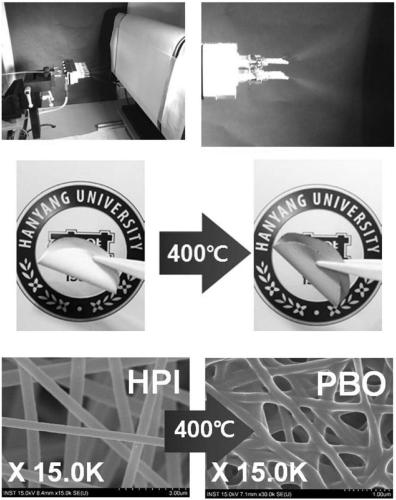

[0137] By the ODPA-HAB that synthetic example 1 obtains 5 -ODA 5 Dissolved in dimethyl acetamide (DMAc) to prepare a 10 wt% solution. Next, 6 mL of the polymer solution was filled in a 10 mL syringe equipped with a 23G needle, and the syringe was installed on the syringe pump of the electrospinning device (ES-robot, NanoNC Company, Korea), and then, according to the conventional electrospinning method, Spinning under silk conditions to obtain electrospun membranes (HPI). The obtained above-mentioned electrospun membrane was placed between an alumina plate and a carbon cloth, and the temperature was raised to 400°C at a rate of 3°C / min in a high-purity argon atmosphere, and then kept in an isothermal state at 400°C for 2 hours. Thermal rearrangement was performed, thereby preparing a thermally rearranged poly(benzoxazole-imide) copolymer electrospun membr...

Embodiment 2 to 9

[0140] [Example 2 to 9] Preparation of thermally rearranged poly(benzoxazole-imide) copolymer support (electrospun membrane)

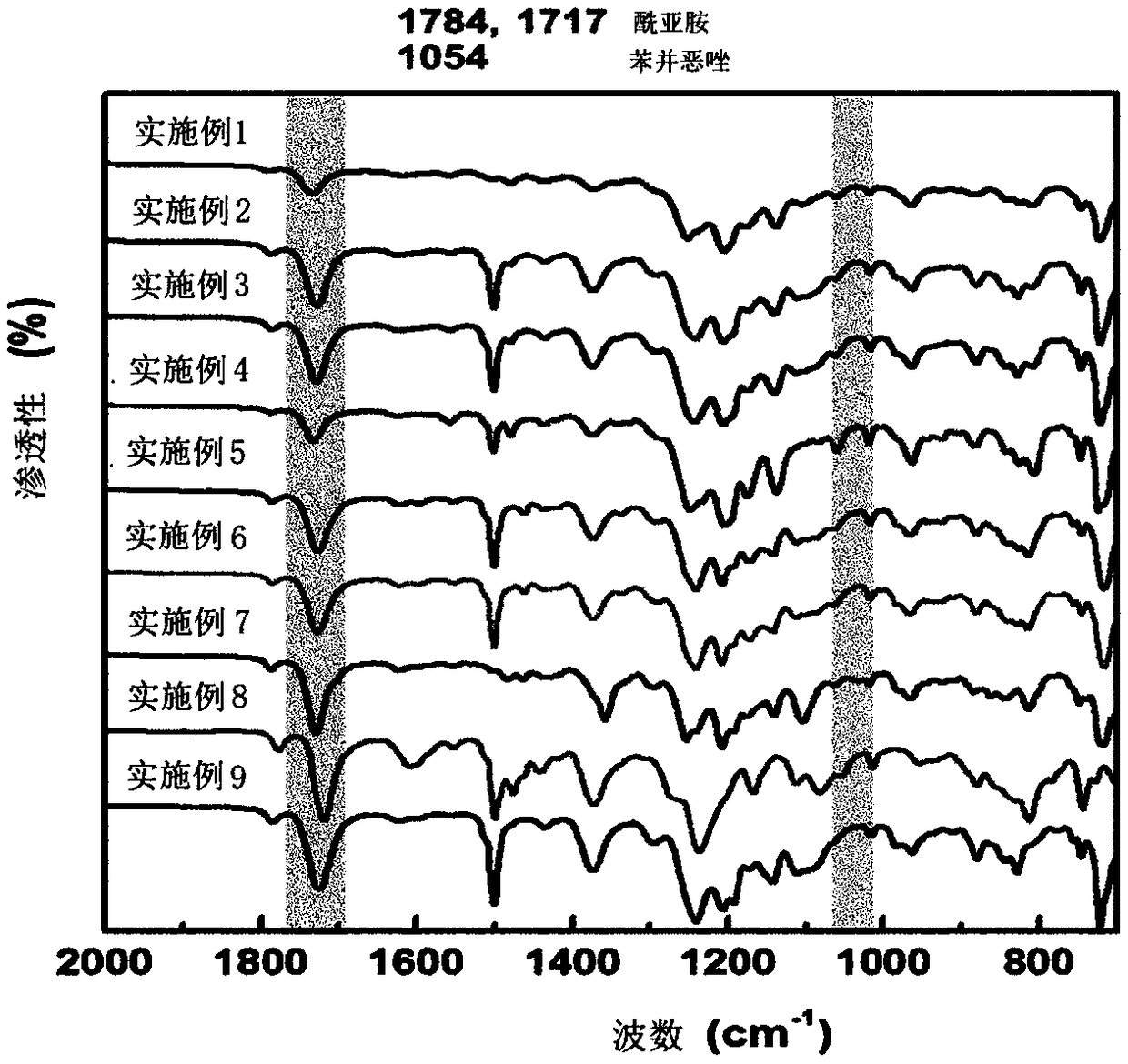

[0141] A thermally rearranged poly(benzoxazole-imide) copolymer electrospun membrane was prepared by the same method as in Example 1 using the samples obtained from Synthesis Examples 2 to 9, and obtained by figure 1 As shown, according to the preparation process of the porous thermally rearranged poly(benzoxazole-imide) copolymer support body (electrospun membrane) and the figure of scanning electron microscope (SEM) according to the above-mentioned embodiments 1 to 9, it can be Porous electrospun membranes in nanofiber morphology were confirmed to have been fabricated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com