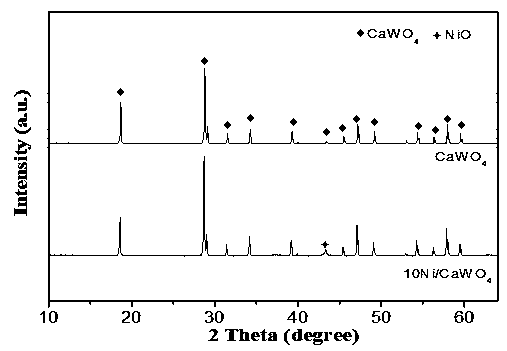

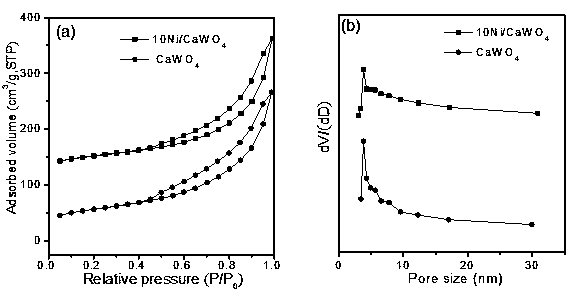

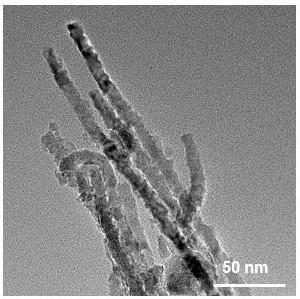

Ordered mesopore scheelite loaded nickel-based bio-oil reforming catalyst

A technology for reforming catalysts and scheelite, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, inorganic chemistry, etc. Low carbon rate, easy carbon accumulation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] (1) Preparation of hard-templated SBA-15.

[0040] Dissolve 4 g of P123 in a mixed solution of 150 mL of deionized water and HCl, which is counted as solution A; add 8 g of tetraethyl orthosilicate (TEOS) dropwise into solution A, and then fully stir; The emulsion is poured into a polytetrafluoroethylene-based reaction kettle, placed in 100 o C in a constant temperature drying oven, stand for crystallization for 24 h; filter the crystallization product precipitated at the bottom of the reaction kettle, wash with deionized water, 50 o Dry at C; transfer the dried powder to a crucible for 500 o C roasting for 6 h, the resulting powder is SBA-15.

[0041] (2) Ordered mesoporous scheelite supports were prepared by dual-solvent hard template method.

[0042] According to the nitrogen physical adsorption results, the pore volume corresponding to 1 g of SBA-15 is calculated to be 2.4 mL. Divide 2.4 mL of distilled water into two equal parts, prepare 1 mol / L sodium tungstate ...

example 2

[0049] (1) Preparation of hard-templated SBA-15.

[0050] Dissolve 3 g of P123 in a mixed solution of 150 mL of deionized water and HCl, which is counted as solution A; add 6 g of tetraethyl orthosilicate (TEOS) dropwise into solution A, and then fully stir; The emulsion is poured into a polytetrafluoroethylene-based reaction kettle, placed in 100 o C in a constant temperature drying oven, stand for crystallization for 36 h; filter the crystallization product precipitated at the bottom of the reaction kettle, wash with deionized water, and o Dry at C; transfer the dried powder to a crucible for 400 o C roasting for 4 h, the resulting powder is SBA-15.

[0051] (2) Ordered mesoporous scheelite supports were prepared by dual-solvent hard template method.

[0052] According to the nitrogen physical adsorption results, the pore volume corresponding to 1.5 g of SBA-15 is calculated to be 2.7 mL. Divide 2.7mL of distilled water into two equal parts, prepare 2 mol / L sodium tungst...

example 3

[0056] (1) Preparation of hard-templated SBA-15.

[0057] Dissolve 5 g of P123 in a mixed solution of 150 mL of deionized water and HCl, which is counted as solution A; add 9 g of tetraethyl orthosilicate (TEOS) dropwise into solution A, and then fully stir; The emulsion is poured into a polytetrafluoroethylene-based reaction kettle, placed in 100 o C in a constant temperature drying oven, stand for crystallization for 24 h; filter the crystallized product precipitated at the bottom of the reaction kettle, wash with deionized water, and dry for 70 o Dry at C; transfer the dried powder to a crucible at 600 o C roasting for 4 h, the resulting powder is SBA-15.

[0058] (2) Ordered mesoporous scheelite supports were prepared by dual-solvent hard template method.

[0059] According to the nitrogen physical adsorption results, the pore volume corresponding to 1 g of SBA-15 is calculated to be 1.76 mL. Divide 1.76mL of distilled water into two equal parts, prepare 0.5 mol / L sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com