Polyolefin nano composite insulation material with high direct-current breakdown strength and preparation method thereof

A technology of breakdown strength and nanocomposite, applied in the field of high-voltage electrical insulating material preparation, can solve problems such as reducing the breakdown strength of polymers, and achieve the effects of improving the DC breakdown strength, improving the interface bonding force, and improving the compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

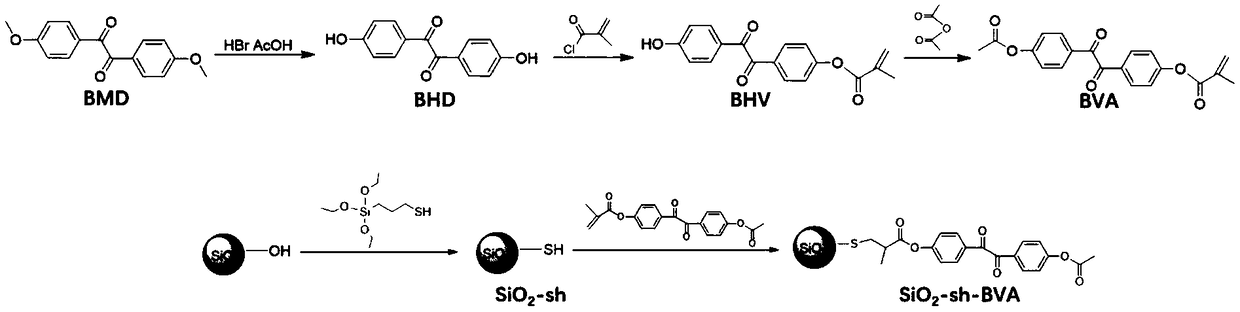

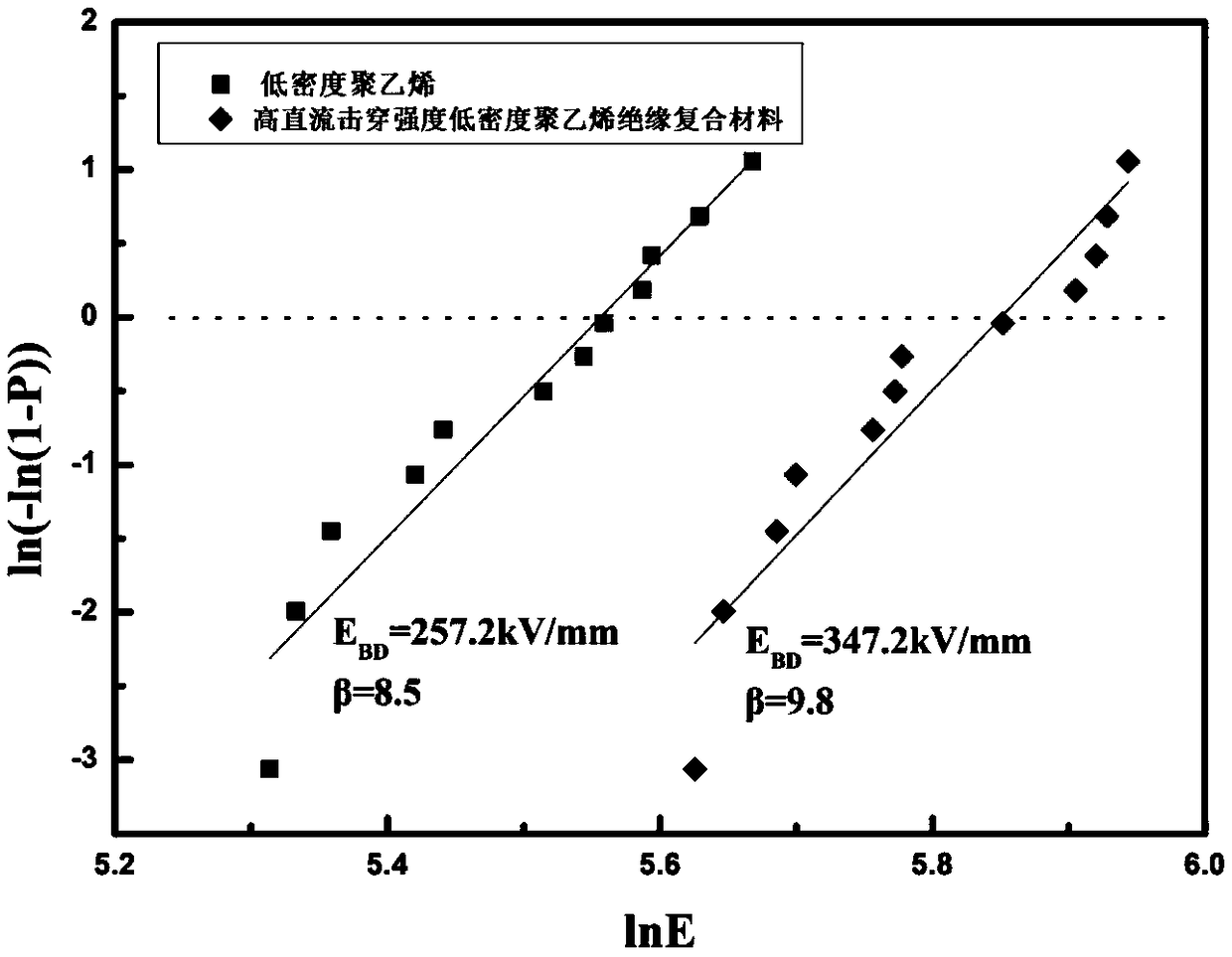

[0050] This embodiment relates to a polyolefin nanocomposite insulating material with high DC breakdown strength, the composite material is made of 98% by mass fraction of low-density polyethylene as a matrix and 2% by mass fraction of voltage stabilizer functionalized nanoparticles as Filling composition. The preparation process of the nanoparticles functionalized by the voltage stabilizer is as follows: figure 1 shown, prepared by the following steps:

[0051] A. Activation of the voltage stabilizer: select p-methoxydiphenyl ethanedione to disperse in hydrobromic acid and acetic acid solution (the volume ratio of hydrobromic acid to acetic acid is 5:1) for reaction, and the solid-to-liquid ratio is 1:20. Reflux reaction for 48h. Then the obtained hydroxylated voltage stabilizer was dissolved in dichloromethane, the solid-to-liquid ratio was 1:10, and the feeding ratio with methacryloyl chloride was 1:1, and reacted in an ice bath under nitrogen protection for 4 hours. The...

Embodiment 2

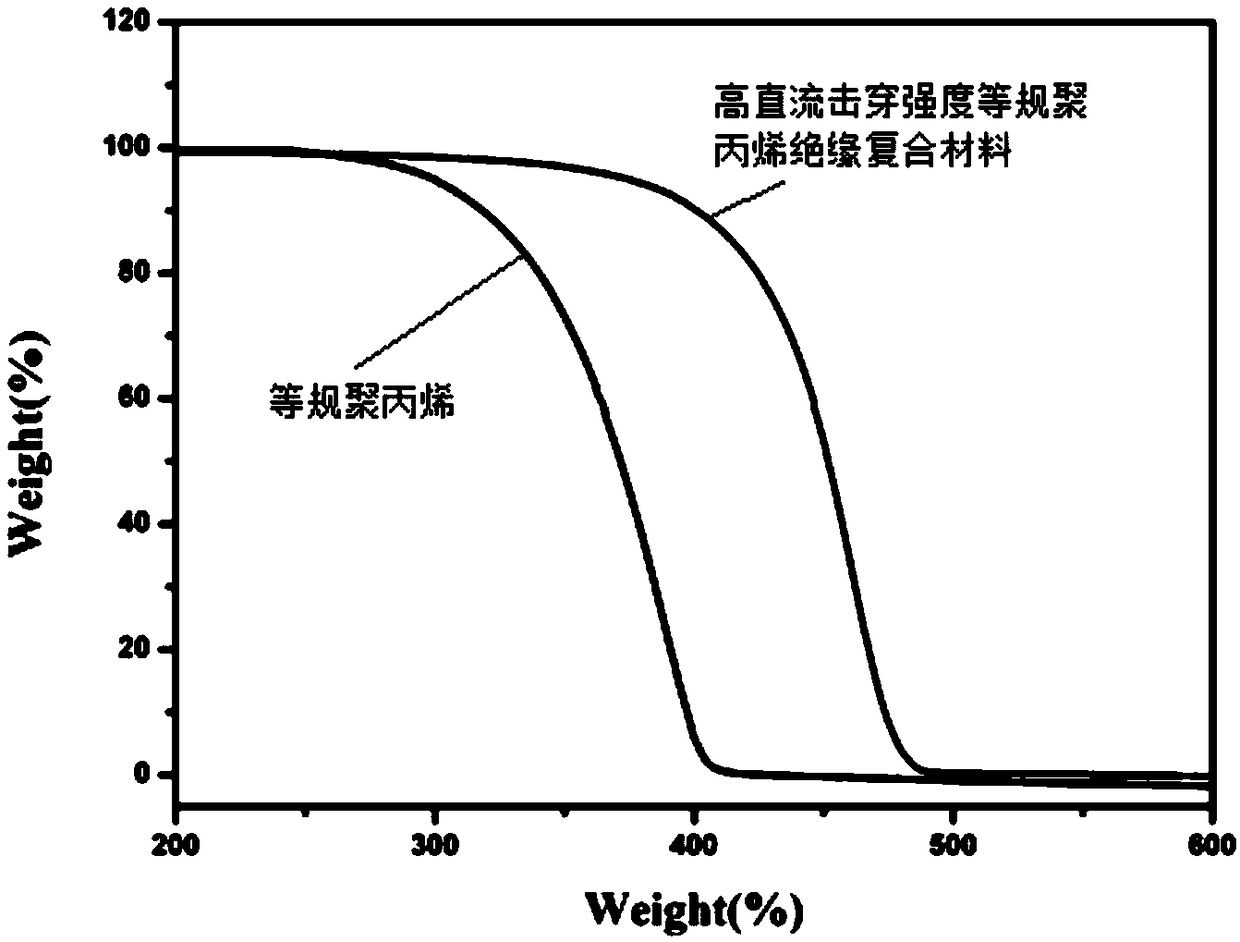

[0059] This embodiment relates to a polyolefin nanocomposite insulation material with high DC breakdown strength, the composite material is made of 99% mass fraction of isotactic polypropylene as a matrix and 1% mass fraction of voltage stabilizer functionalized nanoparticles as Filling composition. The preparation process of the nanoparticles functionalized by the voltage stabilizer is as follows: figure 1 shown, prepared by the following steps:

[0060] A. Activation of voltage stabilizer: Select 2-hydroxy-4-methoxy-9-thioxanthone to disperse in hydrobromic acid and acetic acid solution (hydrobromic acid-acetic acid volume ratio is 2.5:1) for reaction, solid-liquid ratio For 1:30, reflux reaction for 36h. Then the obtained hydroxylated voltage stabilizer was dissolved in dichloromethane, the solid-to-liquid ratio was 1:15, and the feeding ratio with methacryloyl chloride was 1:1, and reacted in an ice bath under nitrogen protection for 2 hours. The obtained product is dis...

Embodiment 3

[0068] This embodiment relates to a polyolefin nanocomposite insulating material with high DC breakdown strength, the composite material is made of 99.75% mass fraction of ethylene-propylene copolymer as a matrix and 0.25% mass fraction of voltage stabilizer functionalized nanoparticles as Filling composition. The preparation process of the nanoparticles functionalized by the voltage stabilizer is as follows: figure 1 shown, prepared by the following steps:

[0069] A. Activation of voltage stabilizer: Select 2-amino-4-methoxy-9-thioxanthone to disperse in hydrobromic acid and acetic acid solution (hydrobromic acid-acetic acid volume ratio is 2:1) for reaction, the solid-to-liquid ratio For 1:25, reflux reaction for 24h. Then the obtained hydroxylated voltage stabilizer was dissolved in dichloromethane, the solid-to-liquid ratio was 1:15, and the feeding ratio with methacryloyl chloride was 1:1, and reacted in an ice bath under nitrogen protection for 2 hours. The obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com