Optical fiber for maintaining vortex beam transmission, and manufacturing method of optical fiber

A vortex beam, optical fiber preform technology, applied in the direction of multi-layer core/clad optical fiber, cladding optical fiber, optical waveguide light guide, etc., can solve the problems of limited transmission distance, OAM beam crosstalk, etc. The effect of low price and low bending loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing an optical fiber for vortex beam transmission and maintenance, which is used to prepare the above-mentioned optical fiber for vortex beam transmission and maintenance, comprising the following steps:

[0037] Step 1, using a deposition method to deposit an inner cladding 2 on the fiber core 1, and then depositing an outer cladding 3 on the inner cladding 2 to form an optical fiber preform to be sintered;

[0038] Step 2, sintering the optical fiber preform at high temperature to form an optical fiber preform to be drawn;

[0039] In step 3, the optical fiber preform is drawn, and at the same time rotated along the axis of the optical fiber preform so that the pitch range is within 0.05-10 mm, and the preparation of the optical fiber is completed.

[0040] In step 1, the deposition method is one or any of improved chemical vapor deposition, furnace chemical vapor deposition, plasma chemical vapor deposition, external vapor deposition, axial vapor d...

Embodiment 1

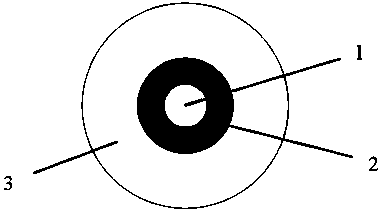

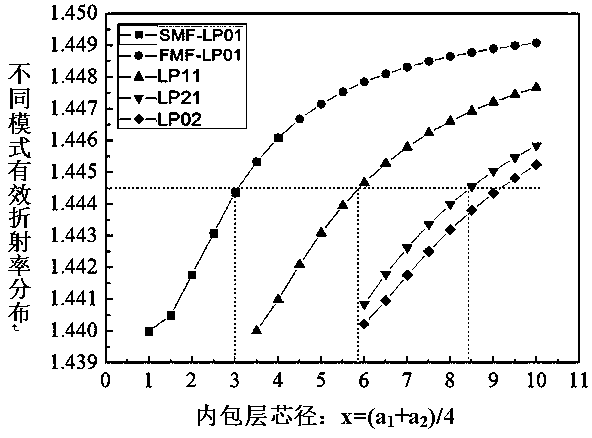

[0042] Such as figure 1 As shown, an optical fiber for vortex beam transmission includes a core 1 with a low refractive index distribution, a ring-shaped inner cladding 2 that surrounds the core 1 and has a certain refractive index distribution, and an outer cladding composed of pure silica Layer 3, the core 1 and inner cladding 2 at a cutoff wavelength greater than 1100nm, only supports LP 01 and LP 11 die, and the LP 01 and LP 11 The refractive index distribution between different modes is as follows image 3 shown. At the same time, the spinning optical fiber with a ring structure with a certain refractive index distribution is prepared by the spinning drawing process, and has different pitch structures, such as Figure 5 As shown, choose Pitch=2.5mm here.

[0043] The optical fiber has a step-type refractive index distribution, wherein the core 1 is a quartz material doped with a small amount of germanium dioxide, the inner cladding 2 is made of fluorine-doped or bor...

Embodiment 2

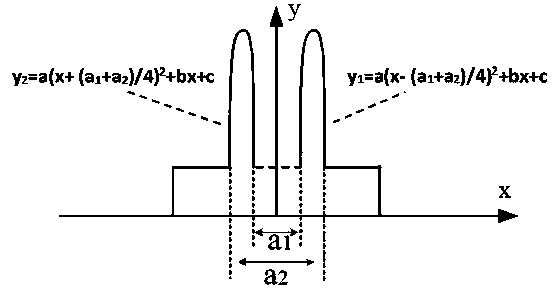

[0045] see figure 2 , image 3 and Figure 4 , the manufacturing steps of an optical fiber applied to vortex beam transmission are as follows:

[0046] Firstly, a germanium-doped cladding layer with high refractive index distribution is sequentially deposited by an improved chemical vapor deposition method, and then a small amount of fluoride or boride quartz inner cladding layer is deposited, or pure quartz is used as the core layer.

[0047] Through chemical vapor deposition technology, high-temperature sintering into a solid or hollow optical fiber preform with a certain pore structure, the core diameter and outer diameter of the preform are 2mm and 15mm respectively;

[0048] The optical fiber preform is drawn into an optical fiber in a drawing tower, and the diameters of the core 1 and the inner cladding 2 are respectively a 1 and a 2 , and rotate along the axis of the optical fiber preform while drawing, and the pitch here is 1.5 mm. Finally, the spinning fiber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com