Graphene-loaded nickel magnetic composite material preparation method

A magnetic composite material and graphene technology, applied in the direction of graphene, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of strong acid affecting the content of metal nickel, long preparation cycle, and low saturation magnetization value of materials, etc., to achieve high Economic value, reduced electromagnetic radiation intensity, high saturation magnetization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

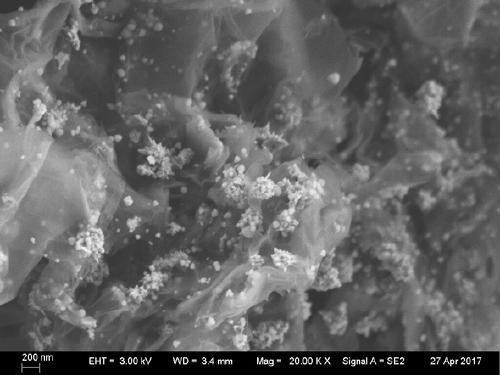

[0025] A preparation method of graphene loaded nickel magnetic composite material, comprising the following steps:

[0026] (1) Select a single-layer or few-layer graphene oxide aqueous solution; the number of layers of graphene has a significant impact on its performance, select a single-layer or few-layer graphene oxide (less than 5 layers) as the carrier of the composite absorbent, and form after the reaction Few-layer graphene, taking advantage of its ultra-high electron mobility and high specific surface area, makes the graphene-loaded nano-nickel magnetic composite material have better conductivity and electromagnetic shielding effect;

[0027] (2) Pre-freeze the graphene oxide aqueous solution first, the pre-freezing temperature is -50~-10°C, and the pre-freezing time>1h, until the graphene oxide solution is completely frozen; Under vacuum conditions, the water in it is directly sublimated from ice to achieve the purpose of drying;

[0028] (3) Then put the frozen grap...

Embodiment 1

[0039] A preparation method of graphene loaded nickel magnetic composite material, comprising the following steps:

[0040] (1) choose monolayer graphene oxide aqueous solution;

[0041] (2) Pre-freezing the graphene oxide aqueous solution first, the pre-freezing temperature is -50~-10°C, and the pre-freezing time>1h, until the graphene oxide solution is completely frozen;

[0042] (3) Then put the graphene oxide solution after freezing into a vacuum drying box, vacuumize and carry out vacuum freeze-drying, the freeze-drying temperature is -45~-25 ℃, and the drying time is 5~20h, so that the graphene oxide solution Water directly sublimates from ice to gas;

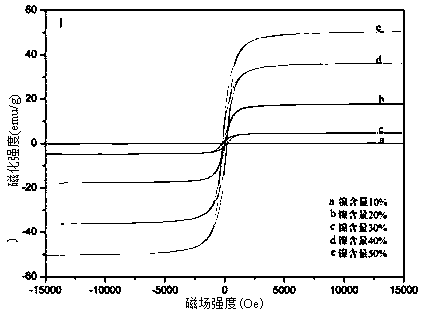

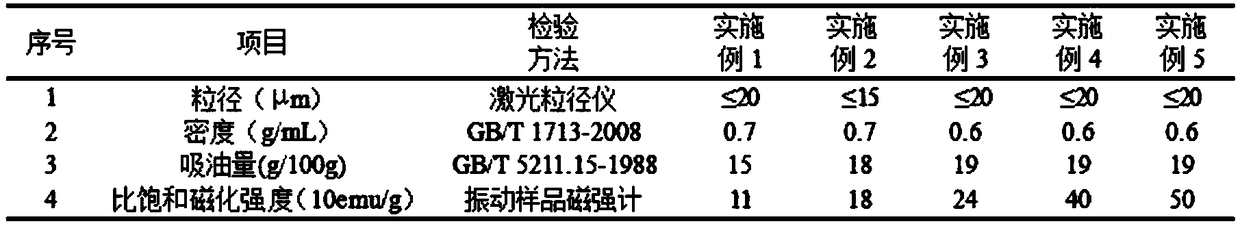

[0043] (4) Evenly disperse the graphene oxide after vacuum freeze-drying in ethylene glycol, then add nickel acetate and hydrazine hydrate in sequence, and at the same time add sodium hydroxide solution to adjust the pH to 13, and ultrasonicate for 5-60 minutes; the amount of graphene oxide The dosage is 2mg / mL, the dosag...

Embodiment 2

[0047] A preparation method of graphene loaded nickel magnetic composite material, comprising the following steps:

[0048] (1) select the few-layer graphene oxide aqueous solution;

[0049] (2) Pre-freezing the graphene oxide aqueous solution first, the pre-freezing temperature is -50~-10°C, and the pre-freezing time>1h, until the graphene oxide solution is completely frozen;

[0050] (3) Then put the graphene oxide solution after freezing into a vacuum drying box, vacuumize and carry out vacuum freeze-drying, the freeze-drying temperature is -45~-25 ℃, and the drying time is 5~20h, so that the graphene oxide solution Water directly sublimates from ice to gas;

[0051] (4) Evenly disperse the graphene oxide after vacuum freeze-drying in ethylene glycol, then add nickel acetate and hydrazine hydrate in sequence, and at the same time add sodium hydroxide solution to adjust the pH to 13, and ultrasonicate for 5-60 minutes; the amount of graphene oxide The dosage is 2mg / mL, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com