A kind of preparation method of manganese nicotinate

A technology of manganese nicotinate and nicotinic acid, applied in organic chemistry, animal husbandry, additional food elements, etc., can solve the problems of easy explosion or fire, relatively high requirements for reaction equipment, and low solubility of sodium chloride, etc. The effect of ruminant milk production, enhanced pig growth performance, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of manganese nicotinate of the present invention is prepared through the following steps:

[0046] at 2m 3 Add 1 t of water to the reactor, add 100kg of nicotinic acid to the water, add 68kg of manganese sulfate monohydrate after heating to 65°C, cover the reactor and stir the reaction for 2.5h, and use sodium hydroxide solution to control the pH value to 5.5 throughout the process , after making it fully reacted, cooled, and centrifuged again, the solid product obtained after centrifugation was washed 3 times, and after flash drying, 123.5 kg of manganese nicotinate product was obtained.

[0047] The filtered mother liquor contains residual nicotinic acid and manganese nicotinate, which is recycled for use in the next batch of reactions; the number of cycles of recycling is 3 to 5 times.

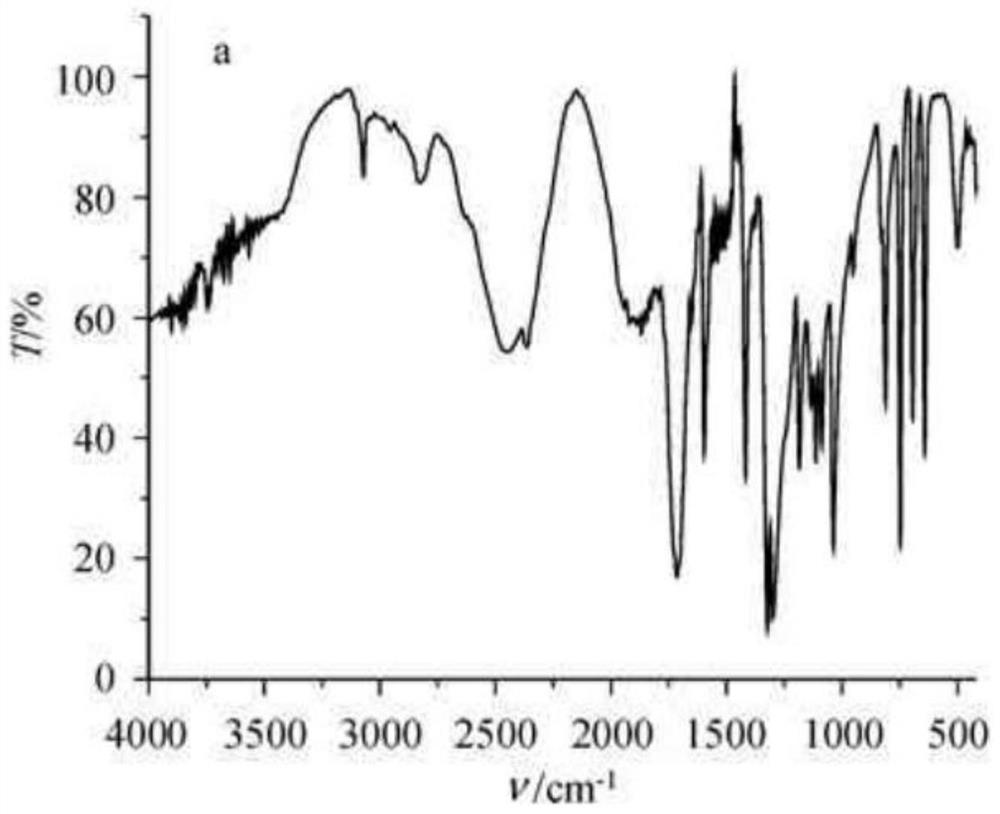

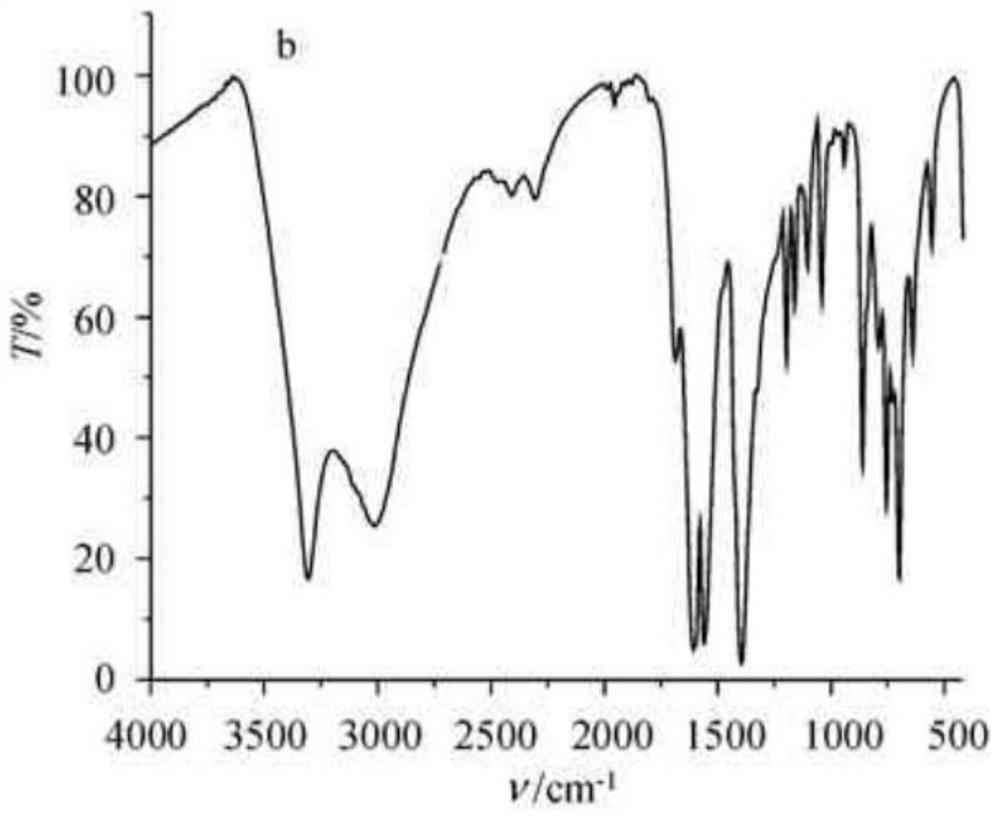

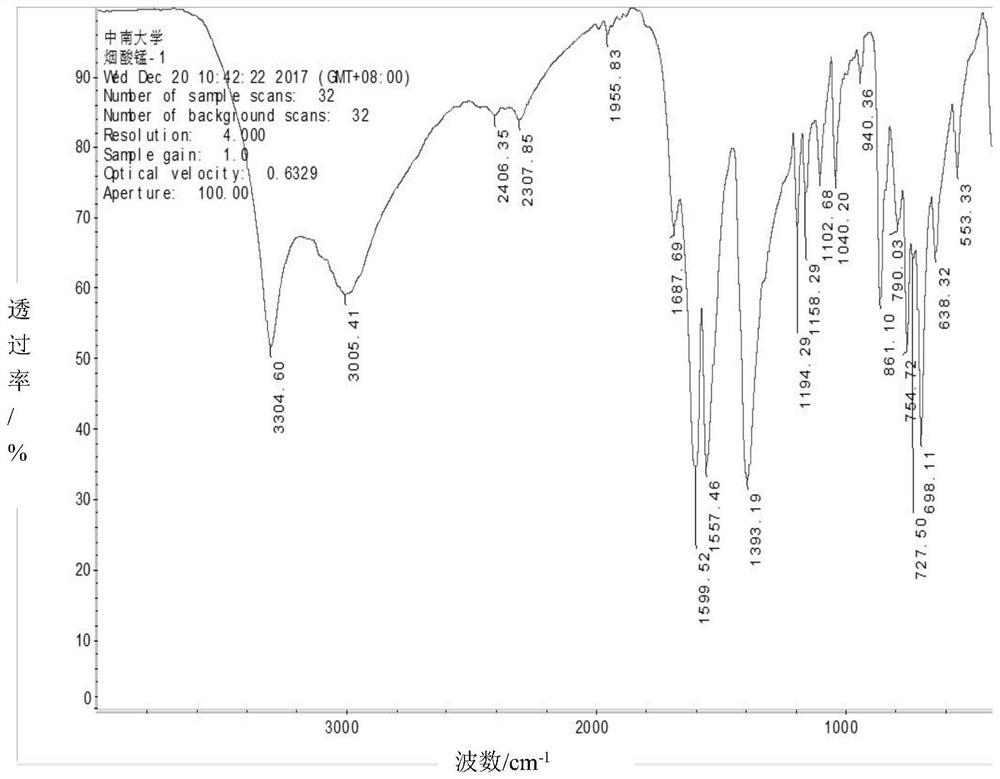

[0048] After detection and analysis, the Mn in the product manganese nicotinate 2+ The mass content is 16.3%, the mass content of niacin ligand is 72.1%, n(C:H...

Embodiment 2

[0059] A preparation method of manganese nicotinate of the present invention is prepared through the following steps:

[0060] at 5m 3 Add 1.8t of water to the reaction kettle of 222kg of niacin, add 36L of isopropanol, heat up to 83°C, add 169kg of manganese sulfate monohydrate, stir for 0.5h, and use sodium hydroxide solution to control the pH value to 6.0, after making it fully reacted, cooling, and then filter-pressing, washing the product obtained after filter-pressing 3 times, drying at 105°C in a drying room and pulverizing to obtain 324.7kg of manganese nicotinate product.

[0061] The filtered mother liquor contains residual nicotinic acid and manganese nicotinate, which is recycled for use in the next batch of reactions; the number of cycles of recycling is 3 to 5 times.

[0062] After detection and analysis, the Mn in the product manganese nicotinate 2+ The mass content is 16.1%, the mass content of niacin ligand is 71.4%, n(C:H:N)≈6:6:1, the water loss rate of th...

Embodiment 3

[0073] A preparation method of manganese nicotinate of the present invention is prepared through the following steps:

[0074] at 5m 3 0.88t of water was added to the reaction kettle of 1, 220kg of niacin was added to the water, the temperature was raised to 30°C, 88L of isopropanol was added, 58kg of manganese oxide was added, the reaction was stirred for 1.5h, and the pH value was controlled to 6.5 with sodium hydroxide solution throughout the process. , after making it fully reacted, cooled, and centrifuged again, the product obtained after centrifugation was washed 3 times, and after flash drying, 271.0 kg of manganese nicotinate product was obtained.

[0075] The filtered mother liquor contains residual nicotinic acid and manganese nicotinate, which is recycled for use in the next batch of reactions; the number of cycles of recycling is 3 to 5 times.

[0076] After detection and analysis, the Mn in the product manganese nicotinate 2+ The mass content is 16.1%, the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com