Method of catalyzing and preparation of 3-hydroxy propionic acid ester by nitrogen-phosphorus coordination metal catalysts

A hydroxypropionate, coordination metal technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low ethylene oxide conversion rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

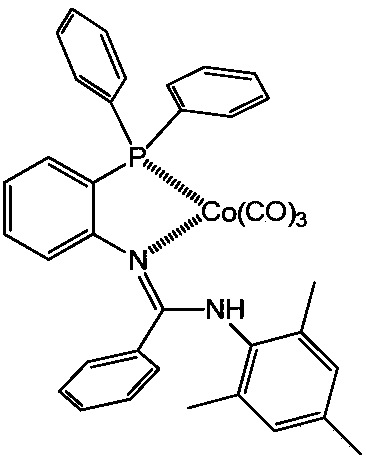

[0027] Catalyst [o-Ph 2 PC 6 h 4 NC(Ph)NH(2,4,6-Me 3 C 6 h 2 ]Co(CO) 3 The catalytic reaction of (1) is completed under an inert atmosphere.

[0028]

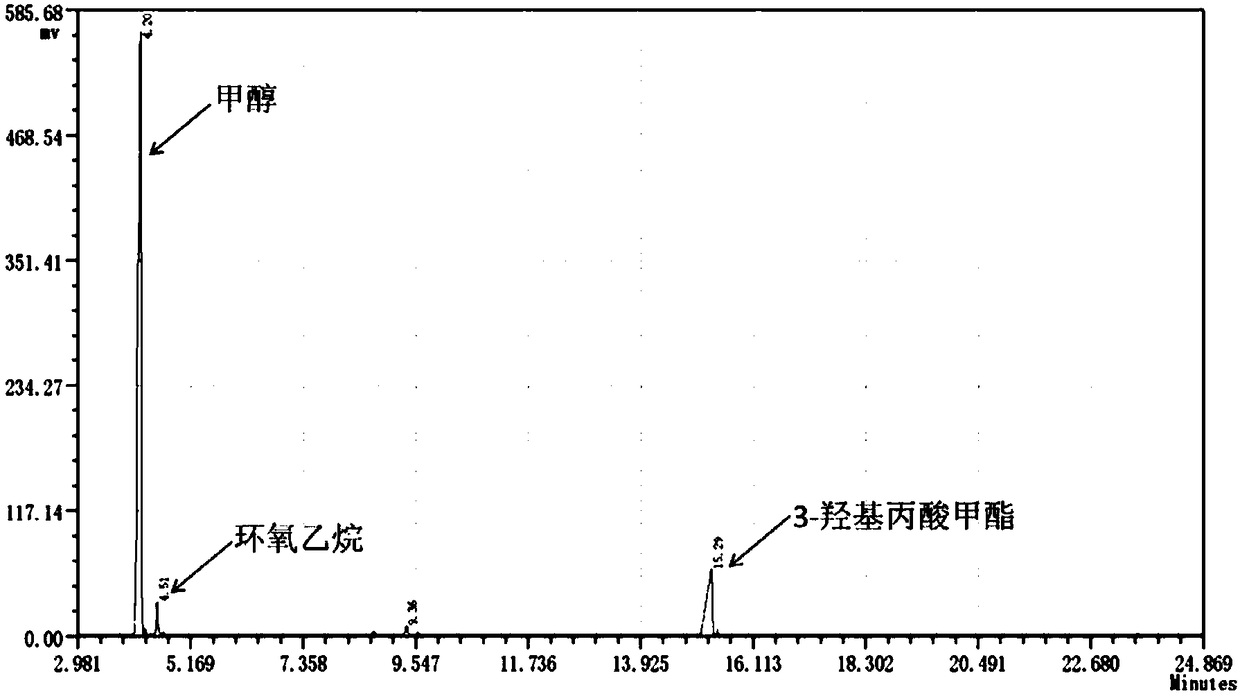

[0029] Select a 300mL autoclave for N 2 After rinsing, add 11mmol, additive 1mmol, ethylene oxide 100mmol, and methanol 40mL in sequence, close the injection valve, connect the carbon monoxide cylinder, heat rapidly to 80°C, and adjust the system pressure to 3.0MPa at the same time, stirring at 800rpm, keeping 3h. After the reaction, the reactor was rapidly cooled to 0°C, the pressure was slowly released to normal pressure, and the reaction solution was extracted for gas chromatography analysis. The chromatographic analysis diagram is shown in figure 1 , and the data results are recorded in Table 1.

Embodiment 2

[0031] The reaction time 3h among the embodiment 1 is changed into 8h, and other operating conditions are unchanged. After the reaction, the reaction solution was analyzed by gas chromatography, and the results are recorded in Table 1.

Embodiment 3

[0033] Catalyst [o-Ph 2 PC 6 h 4 NCH(2-pyridiyl)]Co(CO) 3 The catalytic reaction of (2) is completed under an inert atmosphere.

[0034] Select a 300mL autoclave for N 2 After rinsing, add 2 1mmol, additive 1mmol, ethylene oxide 100mmol, and methanol 40mL in sequence, close the injection valve, connect the carbon monoxide cylinder, heat rapidly to 80°C, and adjust the system pressure to 3.0MPa at the same time, stirring at 800rpm, keeping 3h. After the reaction, the reactor was rapidly cooled to 0°C, and the pressure was slowly released to normal pressure, and the reaction solution was extracted for gas chromatography analysis. The data and results are recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com