Method for preparing coating for sports facility

A technology for sports facilities and coatings, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow drying speed, failure to achieve wear resistance, low coating efficiency, etc., to reduce shearing effect of force, improved dispersion, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

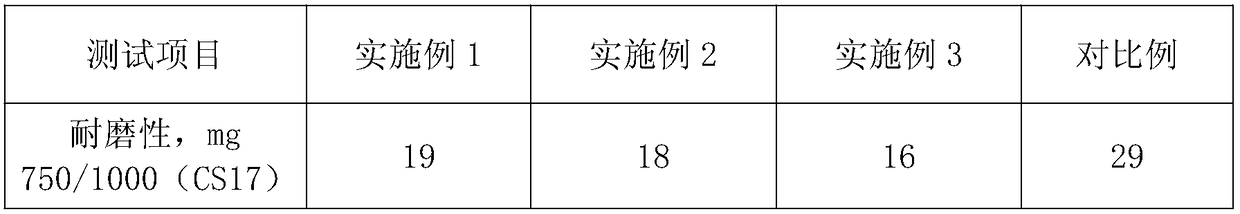

Examples

Embodiment 1

[0033] The preparation method of sports facility coating in the present embodiment is made up of following preparation steps:

[0034] (1) Preparation of acrylic acid prepolymer

[0035] Take the container, add a mixture of 20 parts by weight of butyl acetate and 10 parts by weight of xylene, stir, heat up to 130 ° C, and dropwise add 10 parts by weight of n-butyl acrylate, 15 parts by weight of The mixture formed by mixing ethyl acrylate, 20 parts by weight of methyl methacrylate, 5 parts by weight of styrene, 3 parts by weight of an initiator and 1 part by weight of a chain transfer agent is cooled to 105°C for copolymerization to obtain Acrylic prepolymer.

[0036] (2) Preparation of acrylic modified polyurethane resin

[0037] Take 10 parts by weight of isophorone diisocyanate and add it to the reaction container, add 10 parts by weight of polyethylene glycol and 3 parts by weight of calcium oxide dropwise into the container at a speed of 10ml / min, and raise the temperat...

Embodiment 2

[0044] The preparation method of sports facility coating in the present embodiment is made up of following preparation steps:

[0045] (1) Preparation of acrylic acid prepolymer

[0046]Take the container, add a mixture of 25 parts by weight of butyl acetate and 15 parts by weight of xylene, stir, heat up to 135 ° C, and dropwise add 15 parts by weight of n-butyl acrylate, 20 parts by weight of The mixture formed by mixing ethyl acrylate, 25 parts by weight of methyl methacrylate, 8 parts by weight of styrene, 4 parts by weight of an initiator and 3 parts by weight of a chain transfer agent is cooled to 108°C for copolymerization to obtain Acrylic prepolymer.

[0047] (2) Preparation of acrylic modified polyurethane resin

[0048] Take 15 parts by weight of isophorone diisocyanate and add it to the reaction container, add 12 parts by weight of polyethylene glycol and 4 parts by weight of calcium oxide dropwise into the container at a speed of 12ml / min, and raise the temperat...

Embodiment 3

[0055] The preparation method of sports facility coating in the present embodiment is made up of following preparation steps:

[0056] (1) Preparation of acrylic acid prepolymer

[0057] Take a container, add a mixture of 30 parts by weight of butyl acetate and 20 parts by weight of xylene, stir, heat up to 140 ° C, and dropwise add 20 parts by weight of n-butyl acrylate, 25 parts by weight of The mixture formed by mixing ethyl acrylate, 30 parts by weight of methyl methacrylate, 10 parts by weight of styrene, 5 parts by weight of an initiator and 5 parts by weight of a chain transfer agent is cooled to 110°C for copolymerization to obtain Acrylic prepolymer.

[0058] (2) Preparation of acrylic modified polyurethane resin

[0059] Take 20 parts by weight of isophorone diisocyanate, add it to the reaction container, add 15 parts by weight of polyethylene glycol and 5 parts by weight of calcium oxide dropwise into the container at a speed of 15ml / min, and raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com