Preparation method of protonated titanate nanotubes and adsorption application of protonated titanate nanotubes to uranium and cesium

A technology of nanotubes and titanates, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the influence of hydrothermal temperature and pickling concentration on product morphology. Not studied in depth, not discussed Reaction conditions change the impact of product shape changes, etc., to achieve the effect of low modification cost, improved adsorption and removal ability and anti-interference ability, and uniform product shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

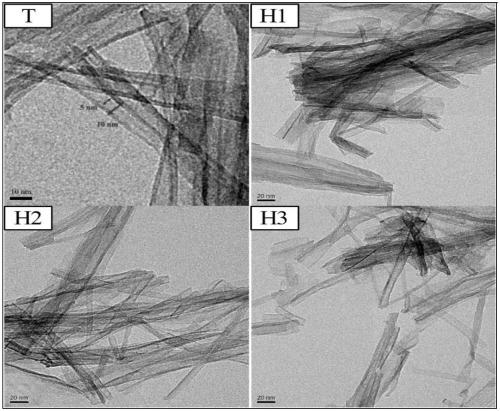

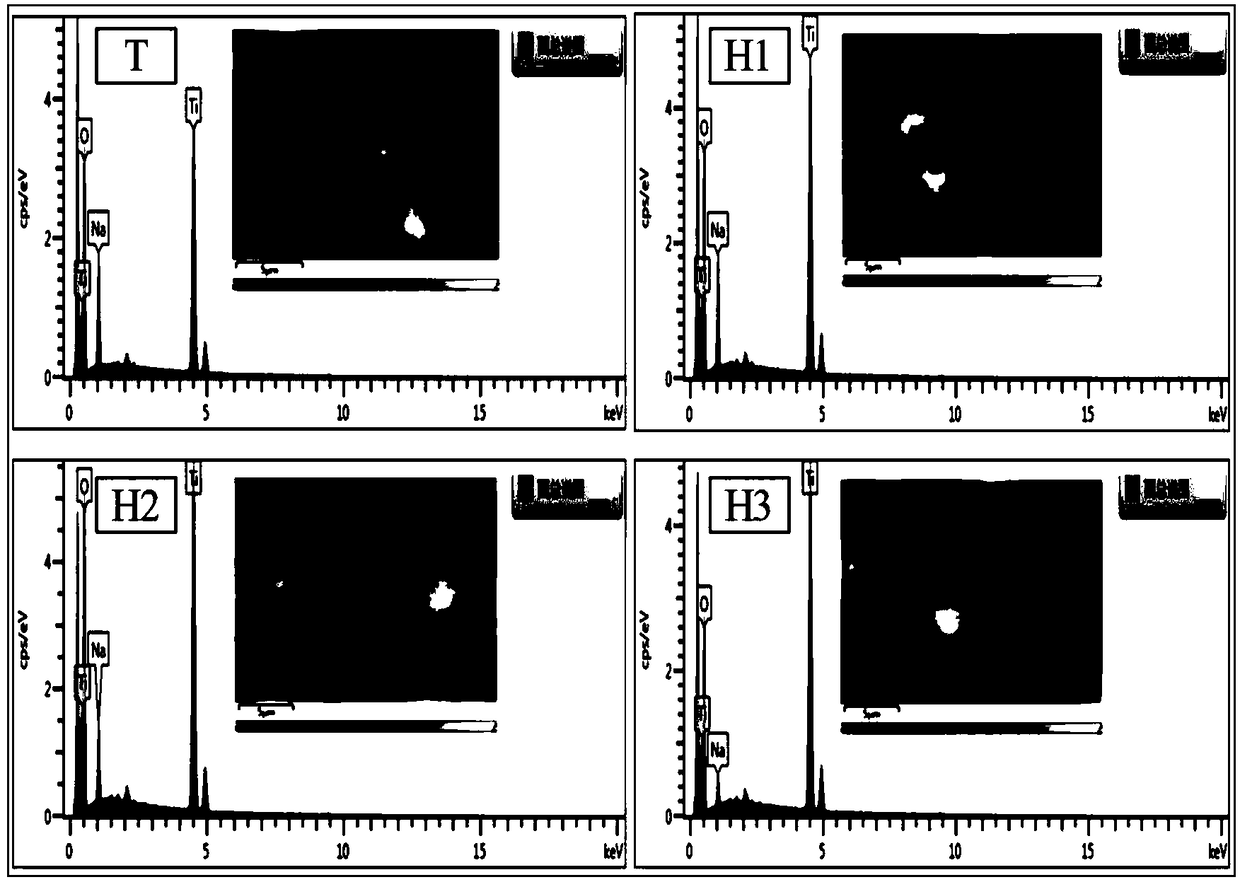

[0028] Different H + / Na + The preparation method of the series protonated titanate nanotubes specifically comprises the following steps:

[0029] (1) Preparation of titanate nanotubes T by hydrothermal method

[0030] Measure 80mL NaOH solution (concentration 8mol / L) in conical flask, add the anatase TiO of 0.8g subsequently 2 Nano-powder, stir for 12 hours until completely mixed; after stirring, transfer the mixture to a polytetrafluoroethylene-lined stainless steel reactor, and place the reactor at 130°C for hydrothermal reaction for 6 hours;

[0031] After the hydrothermal reaction was completed, the reactor was taken out, and after cooling down to room temperature, the mixed solution was centrifuged at 4000r / min for 5 minutes to obtain a white solid; the white solid was washed with deionized water several times until the supernatant was neutral, and then washed with Disperse with ethanol, and finally dry in an oven at 60°C to obtain titanate nanotubes, denoted as T.

...

Embodiment 2

[0037] Influence of concentration change of NaOH solution on product properties during preparation

[0038] In this example, titanate nanotubes T were prepared in the same manner as in Example 1, except that the concentration of the NaOH solution used was increased to 13 mol / L. It is found through characterization that the specific surface area of titanate nanotubes obtained in this example is changed from 203.2m in Example 1 2 / g increased to 332.4m 2 / g. It shows that the change of the concentration of NaOH solution used in the preparation process will affect the properties of the product. In a certain range, the NaOH solution increases, the greater the surface area of the product.

Embodiment 3

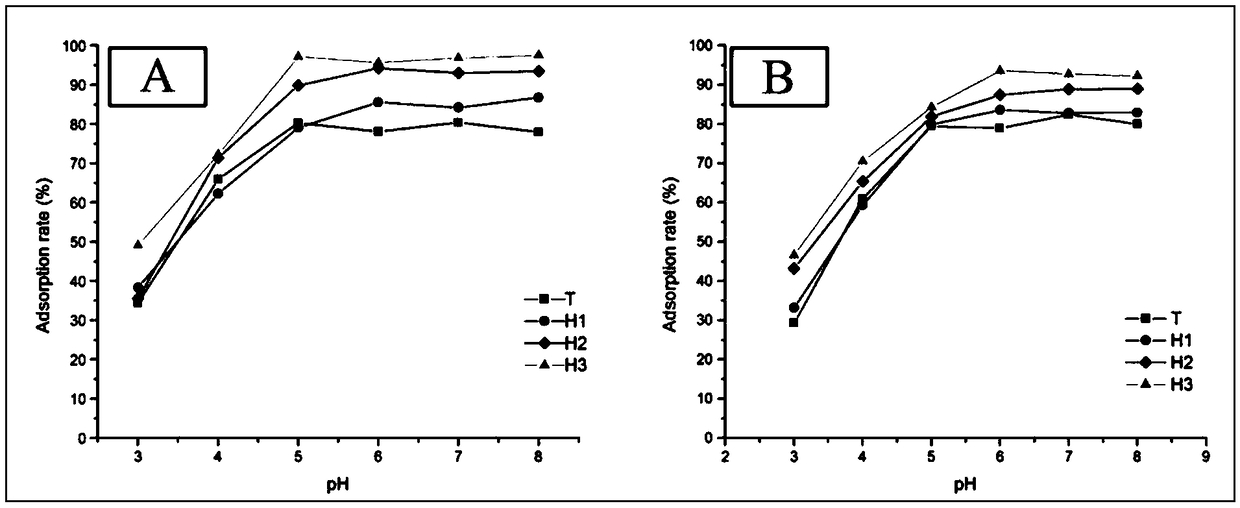

[0040] Adsorption and removal of nuclides uranium and cesium by titanate nanotubes and their series of protonated modified products under different pH conditions

[0041] At a temperature of 25±2°C, 0.004 g of titanate nanotubes T and protonated titanate nanotubes H1, H2, and H3 prepared in Example 1 were sequentially added to four 50-mL centrifuge tubes, followed by 20 mL of initial Concentration of 10mg / L uranium, cesium standard solution (both dosage 0.2g / L). The pH of the reaction system in each centrifuge tube was controlled to be 3, 4, 5, 6, 7, and 8 respectively. Put the four centrifuge tubes in a shaker and vibrate for 1 hour; then take out the centrifuge tubes, and centrifuge each tube at 4000r / min for 5 minutes, take the supernatant to measure the content of uranium and cesium, and study the influence of different pH on the adsorption .

[0042] image 3 It is the influence curve of solution pH on the adsorption of nuclide ions by the titanate nanotubes and their ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| Tube outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com