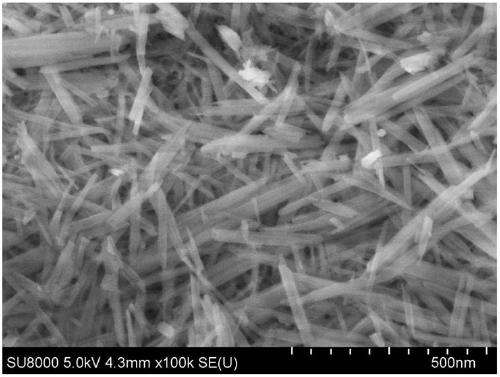

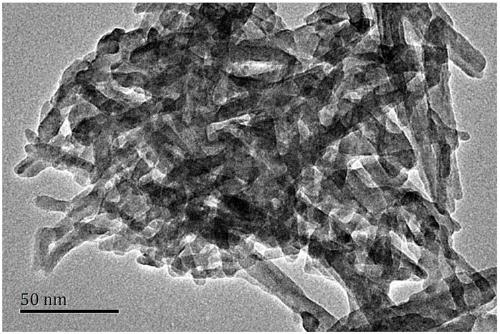

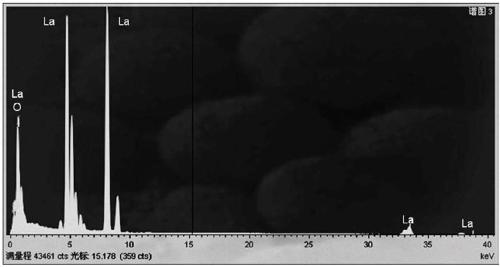

Nanometer lanthanum oxide defluoridation adsorbent and preparation method thereof

An adsorbent, lanthanum hydroxide technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal oxides/hydroxides, etc. Low efficiency and other problems, to achieve the effect of stable adsorption capacity, strong adsorption regeneration performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Step 1. Place the reactor container in ice water at 10°C, and add deionized water to the reactor container;

[0043] Step 2, adding 130g of lanthanum nitrate solid powder into the above-mentioned low-temperature deionized water, stirring and dissolving with a stirrer;

[0044] Step 3, after dissolving, slowly add sodium hydroxide solution to adjust the pH to 8.5; at this time, the mass ratio of water: lanthanum nitrate: sodium hydroxide is 5:2:0.4;

[0045] Step 4, repeatedly rinsing the solution prepared in step 3 with deionized water until the conductivity is below 1 ms / cm;

[0046] Step 5, dehydrate the slurry washed in step 4 with a centrifuge, and dry it in an oven at 90°C;

[0047] Step 6, grinding, and screening through a 100-mesh sieve to obtain dry powder of lanthanum hydroxide;

[0048] Step 7. Mix lanthanum hydroxide dry powder with microcrystalline cellulose and hydroxypropyl methylcellulose, and granulate through a wet granulator and a spheronizer, wherei...

Embodiment 2

[0058] Step 1. Place the reactor container in ice water at 10°C, and add deionized water to the reactor container;

[0059] Step 2, adding 130g of lanthanum nitrate into the above-mentioned deionized water, stirring and dissolving with a stirrer;

[0060] Step 3. Slowly add sodium hydroxide solution to adjust the pH to 9.0; at this time, the mass ratio of water: lanthanum nitrate: sodium hydroxide is 2:1:0.2;

[0061] Step 4, repeatedly rinsing the above solution with deionized water until the conductivity is below 1 ms / cm;

[0062] Step 5, dehydrate the slurry washed in step 4 at 1500r / min with a centrifuge, and dry at 60°C in an oven;

[0063] Step 6, grinding, and screening through a 100-mesh sieve to obtain dry powder of lanthanum hydroxide;

[0064] Step 7. Mix lanthanum hydroxide dry powder with microcrystalline cellulose and hydroxypropylmethyl cellulose, and granulate through a wet granulator and a spheronizer, wherein lanthanum hydroxide: microcrystalline cellulose:...

Embodiment 3

[0067] Step 1. Place the reactor vessel in ice water at 10°C; add deionized water to the reactor vessel;

[0068] Step 2, adding 130g of lanthanum nitrate into the above water, stirring and dissolving with a stirrer;

[0069] Step 3. Slowly add sodium hydroxide solution to adjust the pH to 9.0; at this time, the mass ratio of water: lanthanum nitrate: sodium hydroxide is 7:4:0.1;

[0070] Step 4, repeatedly rinsing the above solution with deionized water until the conductivity is below 1 ms / cm;

[0071] Step 5, dehydrate the slurry washed in step 4 with a centrifuge, and dry it in an oven at 90°C;

[0072] Step 6, grinding, and screening through a 100-mesh sieve to obtain dry powder of lanthanum hydroxide;

[0073] Step 7. Mix lanthanum hydroxide dry powder with microcrystalline cellulose and hydroxypropyl methylcellulose, and granulate through a wet granulator and a spheronizer, wherein, lanthanum hydroxide: microcrystalline cellulose: hydroxypropyl methylcellulose The mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com