Novel method for rapidly preparing mesoporous SAPO-34 molecular sieve with small particle size

A technology of SAPO-34 and molecular sieve, which is applied in the direction of molecular sieve catalysts, including molecular sieve catalysts, molecular sieves and alkali-exchanged phosphates, can solve the problems of industrial application and cost, achieve long catalyst life, improve olefin yield, and high ratio Surface and Pore Volume Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

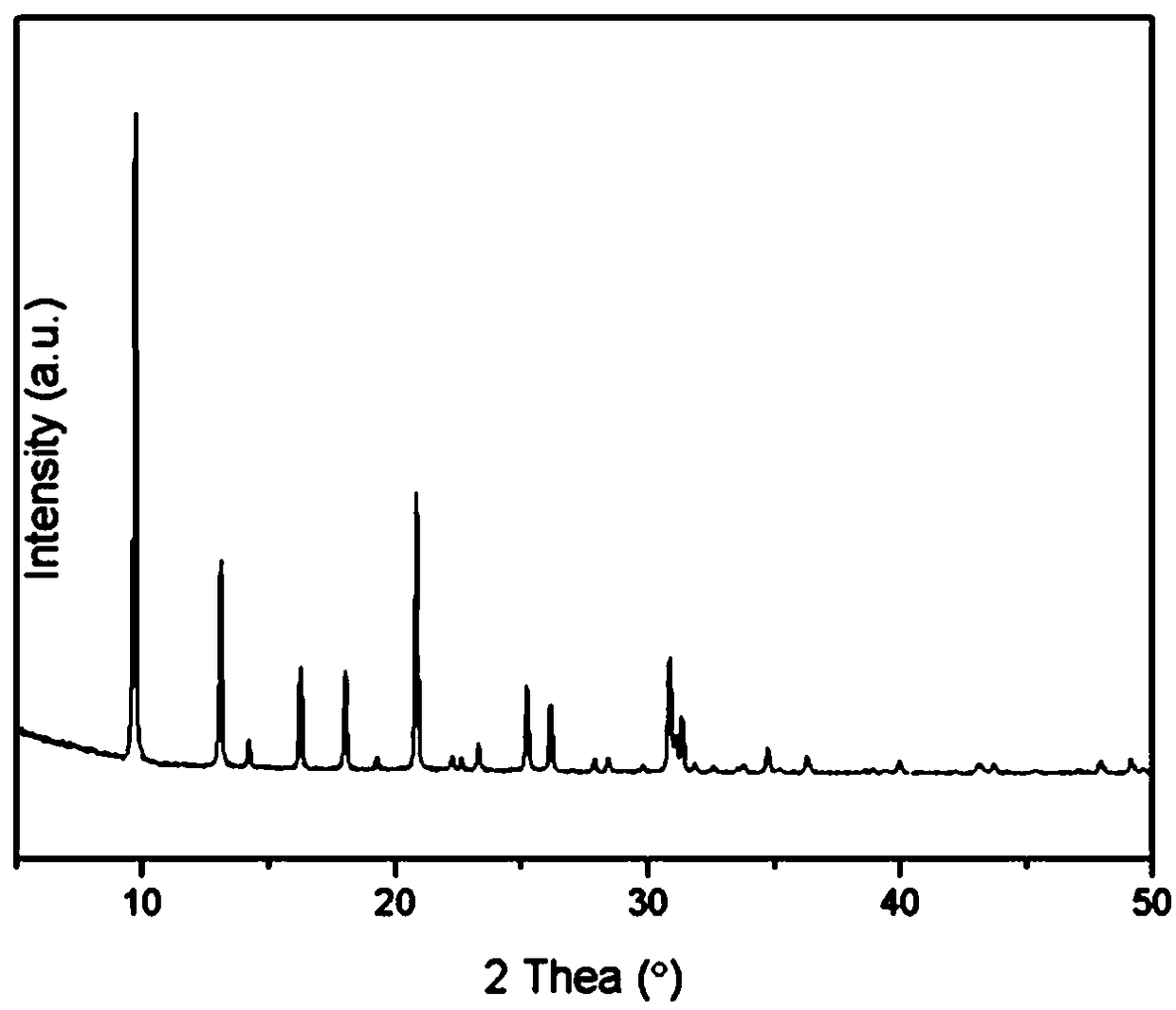

Embodiment example 1

[0041] Example 1: Mix 0.8 mol of 85% phosphoric acid and 50 mol of water evenly to form a transparent solution. Slowly add 1 mol of alumina powder to the above solution to form a translucent slurry, add 0.1 mol of silica gel to the slurry at one time, add 1.0 mol of template agent under stirring, after adding, mix well at room temperature , transfer and seal the above slurry to a high-pressure reaction tank, heat up to 80 degrees and continue stirring for 24 hours. Then add 3.0 mol of mesoporous agent ethylene glycol amine (substituent R=H), mix evenly, heat up to 200 degrees at 25 degrees per hour, and crystallize for 3 hours under autogenous pressure of 200 degrees. After crystallization, The valve is opened to allow the water vapor to evaporate and the condensate is collected for reuse. The residue was cooled, the solid crystals were separated by filtration, washed with deionized water until neutral, and the solid was dried at 100°C under normal pressure. The obtained prod...

Embodiment example 2

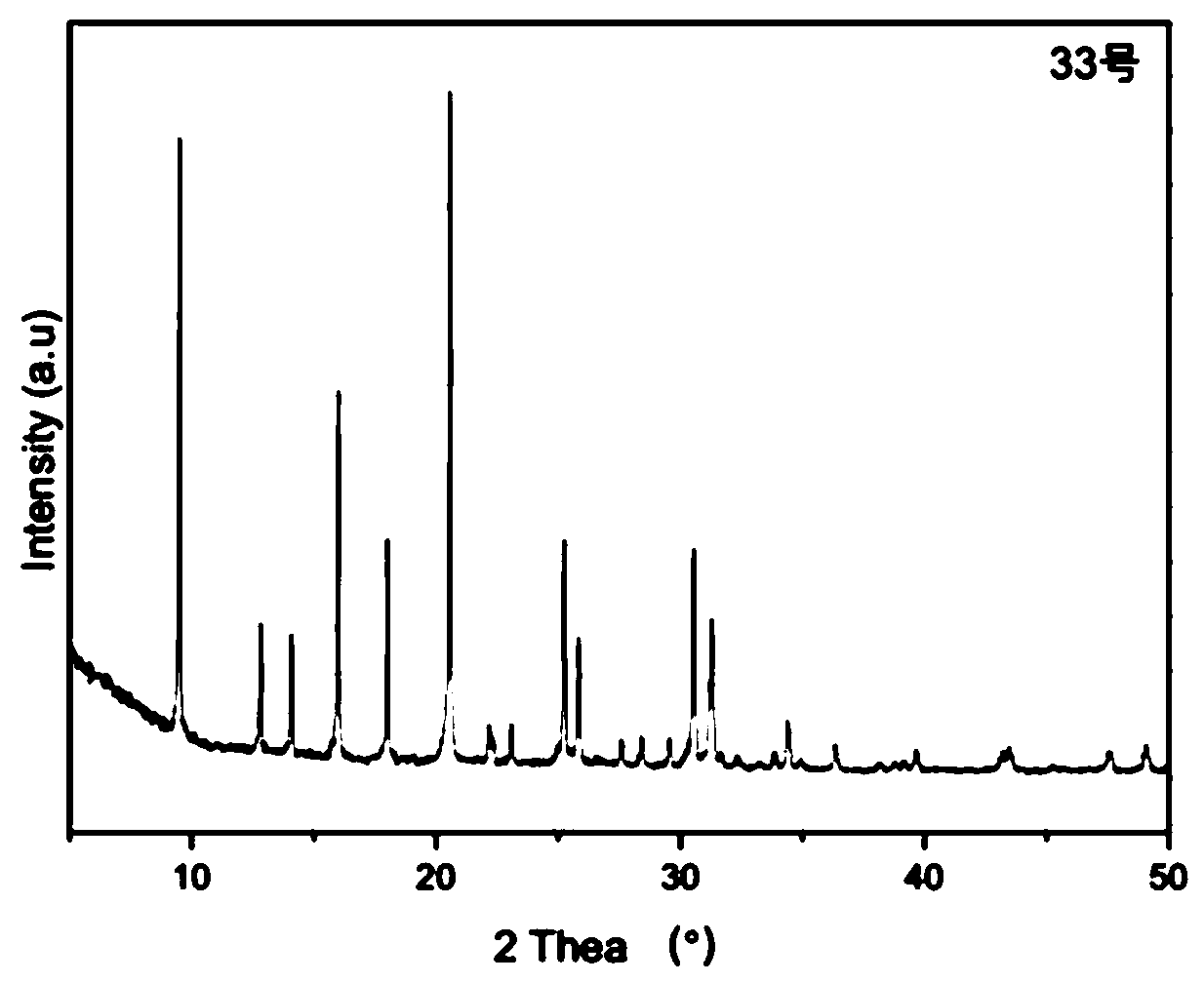

[0046] Example 2: N-methyl substituted ethylene glycol amine as a pore-forming agent (substituent R=CH3). Mix 0.8 mol of 85% phosphoric acid and 50 mol of water to form a transparent solution. Slowly add 1 mol of alumina powder to the above solution to form a translucent slurry, add 0.1 mol of silica gel to the slurry at one time, add 1.0 mol of template agent under stirring, after adding, mix well at room temperature , transfer and seal the above slurry to a high-pressure reaction tank, and continue to stir for 24 hours. Then add 3.0 mol of mesoporous agent: N-methyl substituted ethylene glycol amine, raise the temperature to 200 degrees, and crystallize for 3 hours under the autogenous pressure of 200 degrees. After crystallization, open the valve to allow the water vapor to evaporate, and condense to collect Reuse. The residue was cooled, the solid crystals were separated by filtration, washed with deionized water until neutral, and the solid was dried at 100°C under norm...

Embodiment example 3

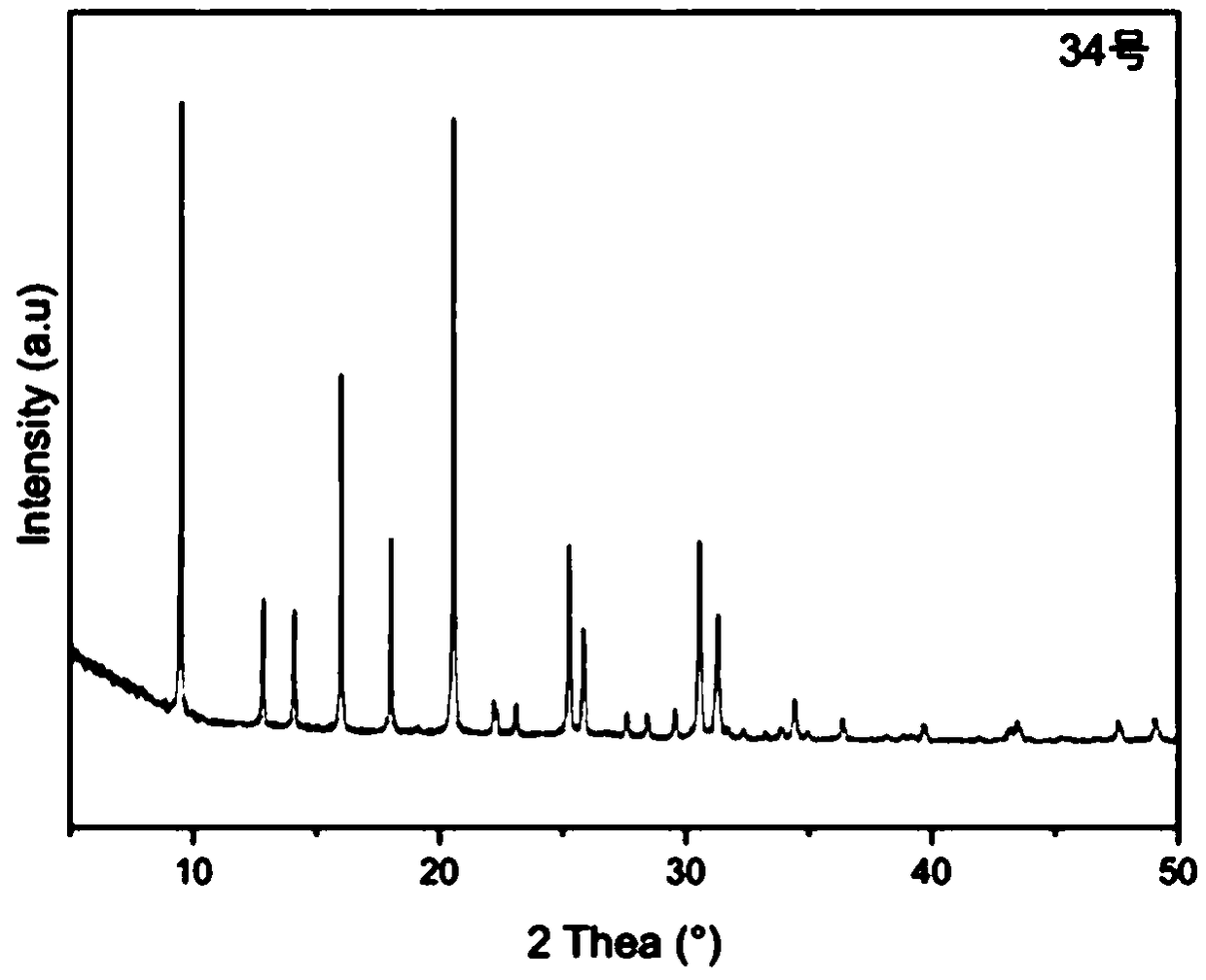

[0047] Example 3: N-ethyl substituted ethylene glycol amine as a pore forming agent (substituent R=CH2CH3). Mix 0.8 mol of 85% phosphoric acid and 50 mol of water to form a transparent solution. Slowly add 1 mol of alumina powder to the above solution to form a translucent slurry, add 0.1 mol of silica gel to the slurry at one time, add 1.0 mol of template agent under stirring, after adding, mix well at room temperature , transfer and seal the above slurry to a high-pressure reaction tank, and continue to stir for 24 hours. Then add 3.0 mol of mesoporous agent: N-ethyl substituted ethylene glycol amine, raise the temperature to 200 degrees, and crystallize for 3 hours under the autogenous pressure of 200 degrees. After crystallization, open the valve to allow the water vapor to evaporate, and condense to collect Reuse. The residue was cooled, the solid crystals were separated by filtration, washed with deionized water until neutral, and the solid was dried at 100°C under nor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com