Method for improving surface load of graphene on surface of polyester fabric

A polyester fabric, surface loading technology, applied in textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of chemical environmental pollution, difficult finishing, low hygroscopicity, etc., achieve low cost, simple loading process, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

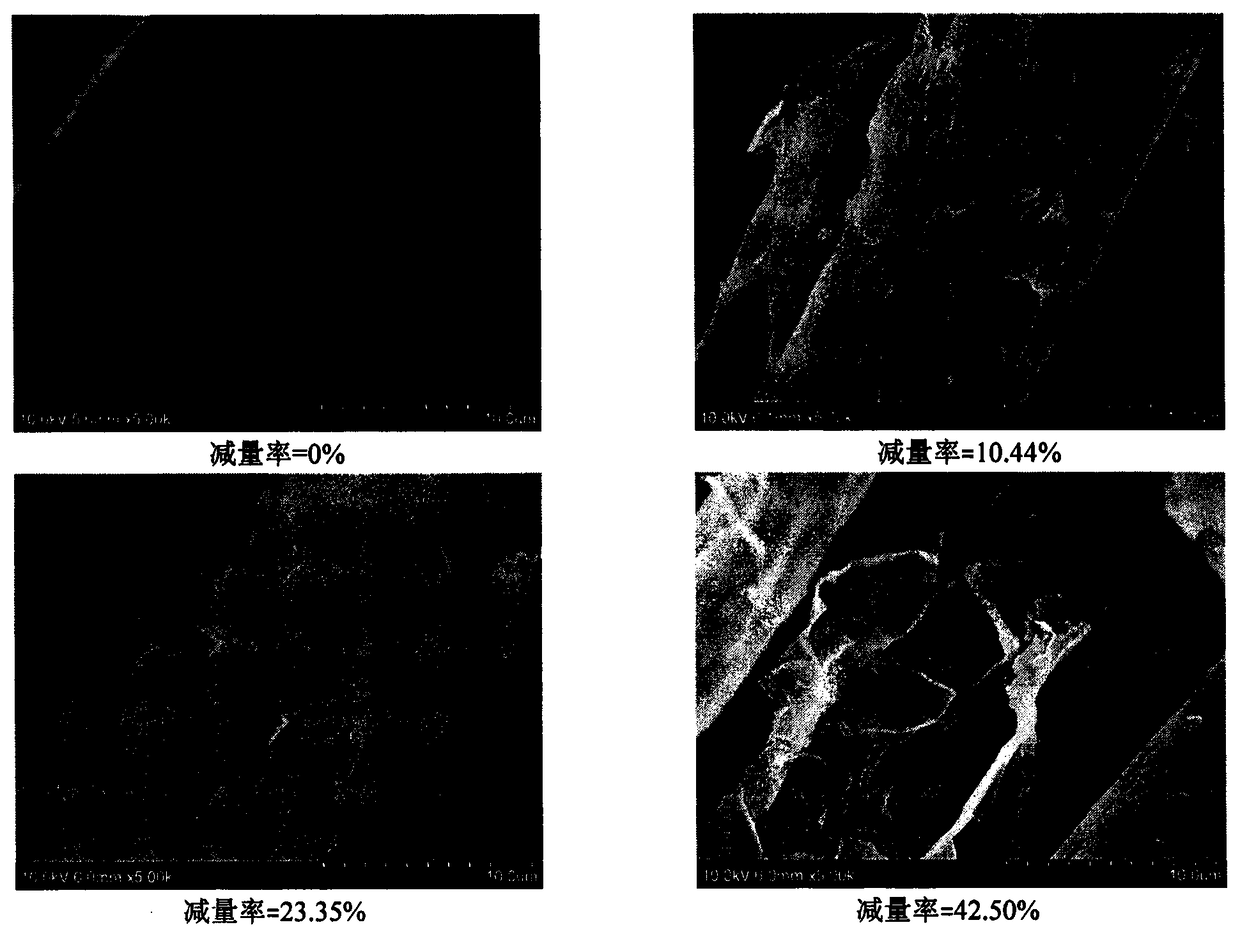

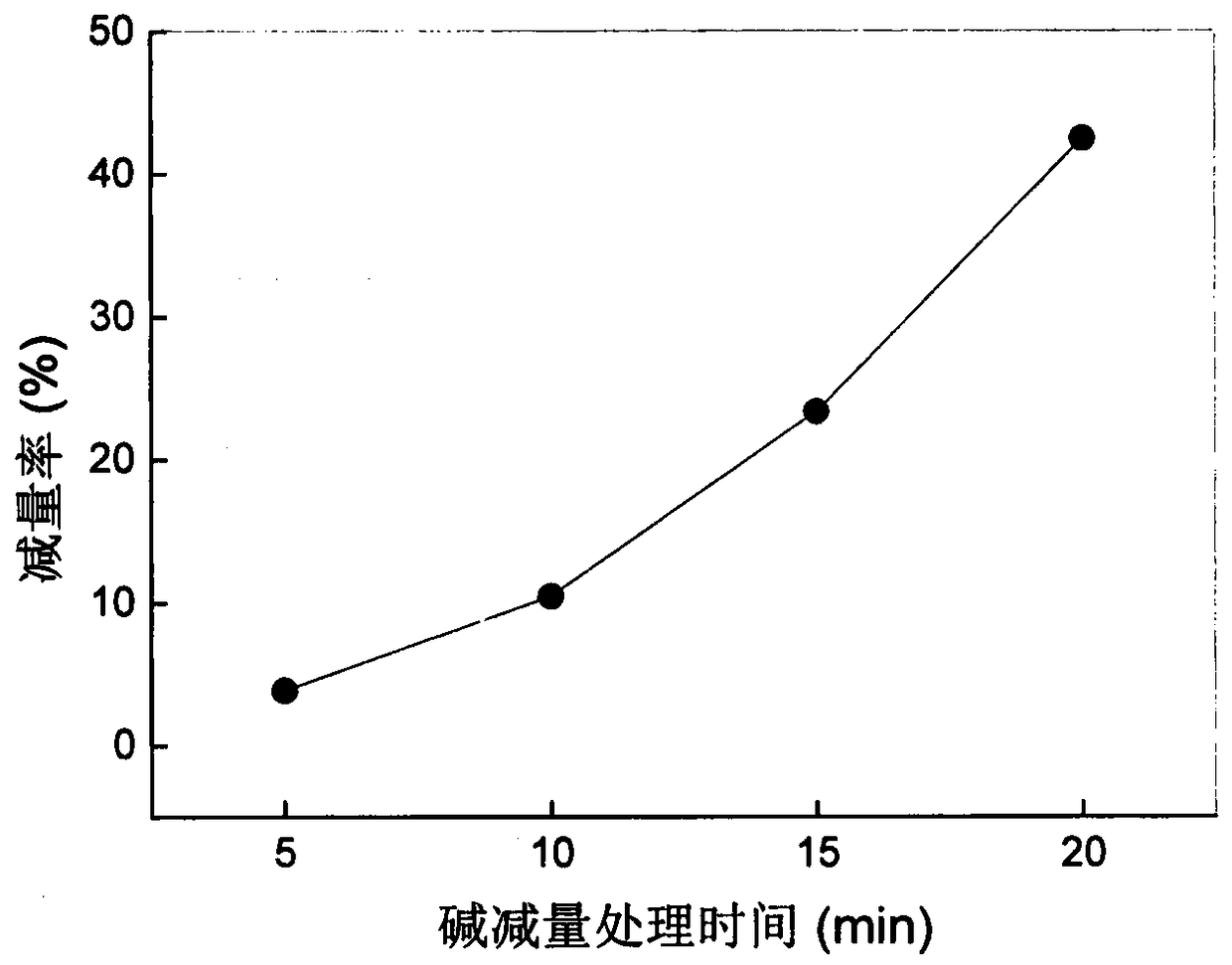

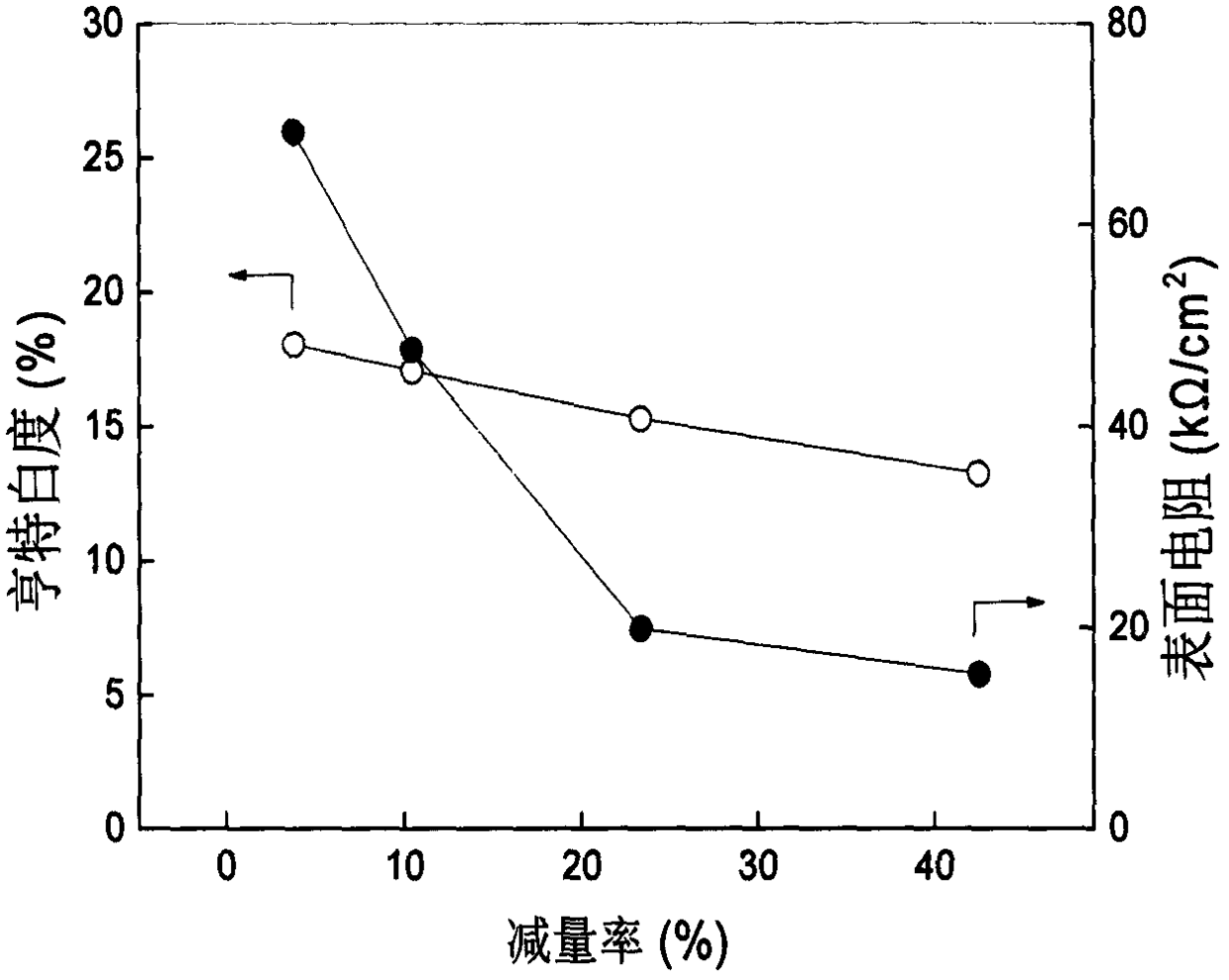

[0025] 1. Alkali weight reduction treatment of polyester fabric

[0026] First prepare the ethanol aqueous solution of sodium hydroxide, wherein the concentration of sodium hydroxide is 100 g / liter, and the mass fraction of ethanol aqueous solution is 20%. Then place the solution in a constant temperature water bath and heat it up to 85°C, add the polyester fabric at a bath ratio of 1:50, and then mechanically stir it. After reacting for 20 minutes, take out the fabric, and finally wash it with distilled water three times after fully washing it with water. Dry at 45°C, place the obtained alkali-treated polyester fabric in a dryer for 6 to 12 hours, and use the weight loss method to calculate its weight reduction rate;

[0027] 2. Preparation of graphene oxide aqueous dispersion

[0028] Put 0.50 grams of graphene oxide powder and 199.5 grams of distilled water in a beaker, stir with a magnetic stirrer for 5 minutes at room temperature, and then use an ultrasonic cell crusher ...

Embodiment 2

[0034] 1. the reaction time of described dacron fabric in sodium hydroxide solution is 15 minutes, and all the other are identical with the 1st step process among the embodiment 1;

[0035] 2. Same as step 2 of embodiment 1;

[0036] 3. Same as step 3 of embodiment 1;

[0037] 4. Same as step 4 of embodiment 1;

Embodiment 3

[0039] 1. the reaction time of described dacron fabric in sodium hydroxide solution is 10 minutes, and all the other are identical with the 1st step process among the embodiment 1;

[0040] 2. Same as step 2 of embodiment 1;

[0041] 3. Same as step 3 of embodiment 1;

[0042] 4. Same as step 4 of embodiment 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com