A kind of superconducting material and preparation method thereof for NMR human body imaging

A technology for superconducting materials and human imaging, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., which can solve the problems of low superconducting transition temperature, degradation of superintercepting current capability, and high cost of helium gas , to achieve high electrical conductivity, improve high temperature resistance, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

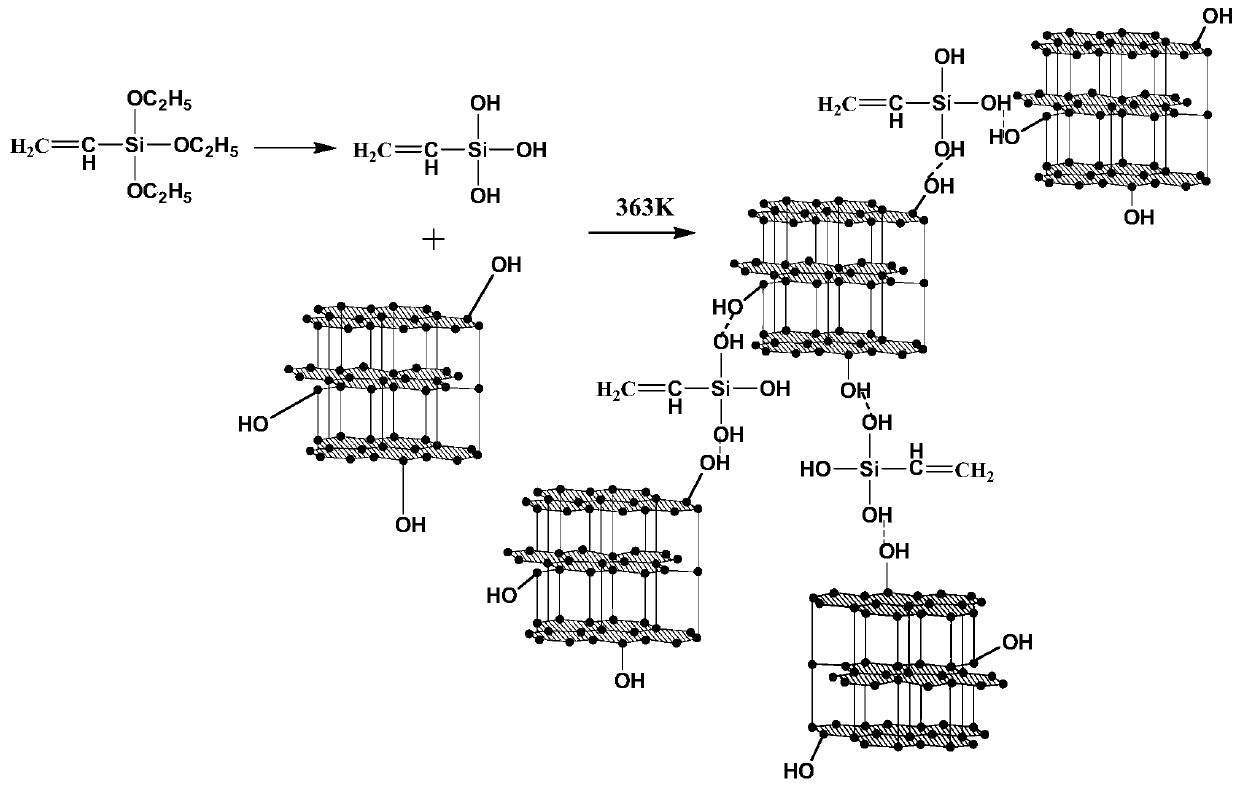

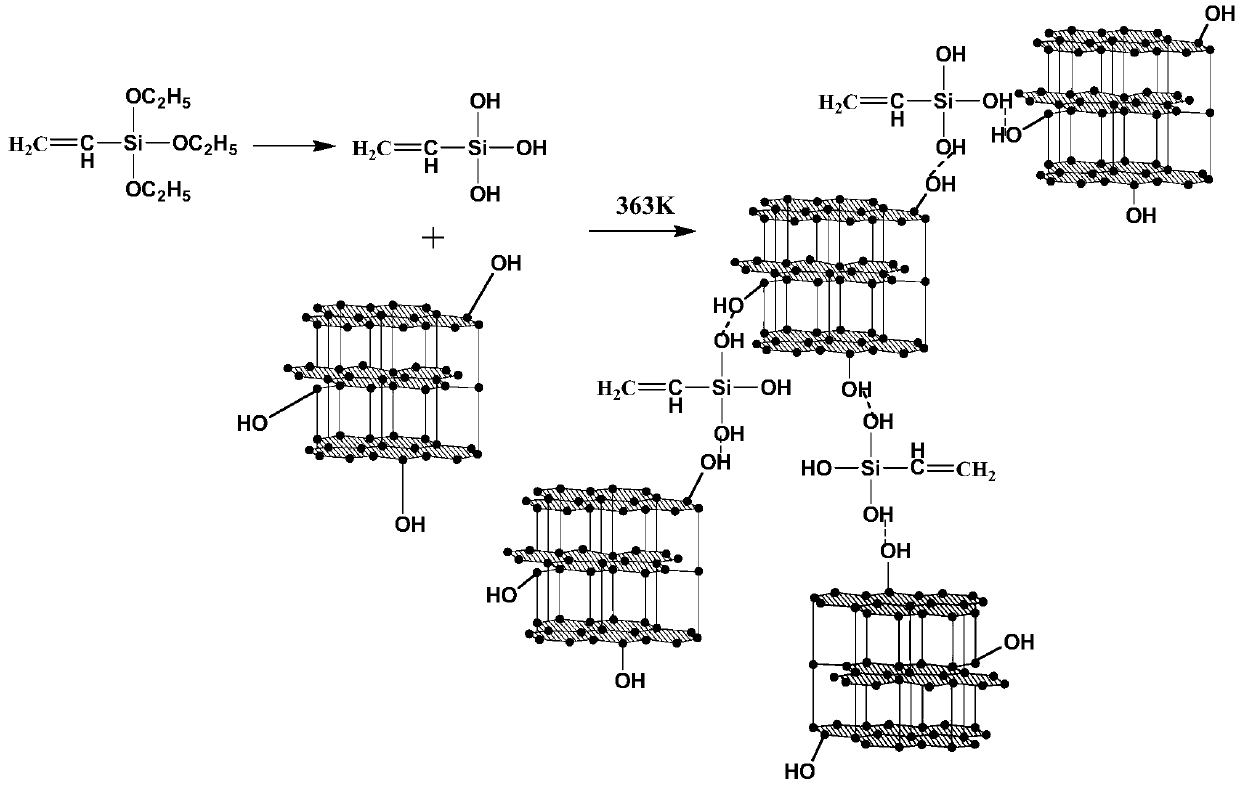

[0026] The specific preparation process of modified graphite powder is as follows: Weigh 1kg of graphite and add it to 8L ethanol solution, ultrasonically disperse it at room temperature for 10min, add the dispersed graphite solution into a three-necked flask, raise the temperature to 90°C, and add 0.85kg Sodium dodecylbenzenesulfonate, after stirring and reacting for 5min, 1.32kg of vinyltriethoxysilane was added thereto, reacted at constant temperature for 1h, then filtered, washed and dried, and the obtained product was ground to obtain modified graphite powder;

[0027] The specific preparation process of carbon / titanium doped magnesium diboride is as follows:

[0028] Add 1kg of magnesium diboride and 0.83kg of nano-titanium dioxide into 3L of acetic acid, mix evenly to obtain a sol, put the sol into a tube furnace at 300°C and roast for 2 hours, then heat up to 650°C and bake for 1 hour, then cool down to 200°C and take it out. A carbon / titanium doped magnesium diboride ...

Embodiment 2

[0030] The specific preparation process of modified graphite powder is as follows: Weigh 1kg of graphite and add it to 8L ethanol solution, ultrasonically disperse it at room temperature for 10min, add the dispersed graphite solution into a three-necked flask, raise the temperature to 90°C, and add 0.87kg Sodium dodecylbenzenesulfonate, after stirring and reacting for 5min, 1.32kg of vinyltriethoxysilane was added thereto, reacted at constant temperature for 1h, then filtered, washed and dried, and the obtained product was ground to obtain modified graphite powder;

[0031] The specific preparation process of carbon-doped magnesium diboride is as follows:

[0032] Add 1 kg of magnesium diboride into 3 L of acetic acid, mix well to obtain a sol, put the sol into a tube furnace at 300°C and roast for 2 hours, then heat up to 650°C and bake for 1 hour, then cool down to 200°C and take it out to obtain a carbon-doped bismuth Magnesium boride.

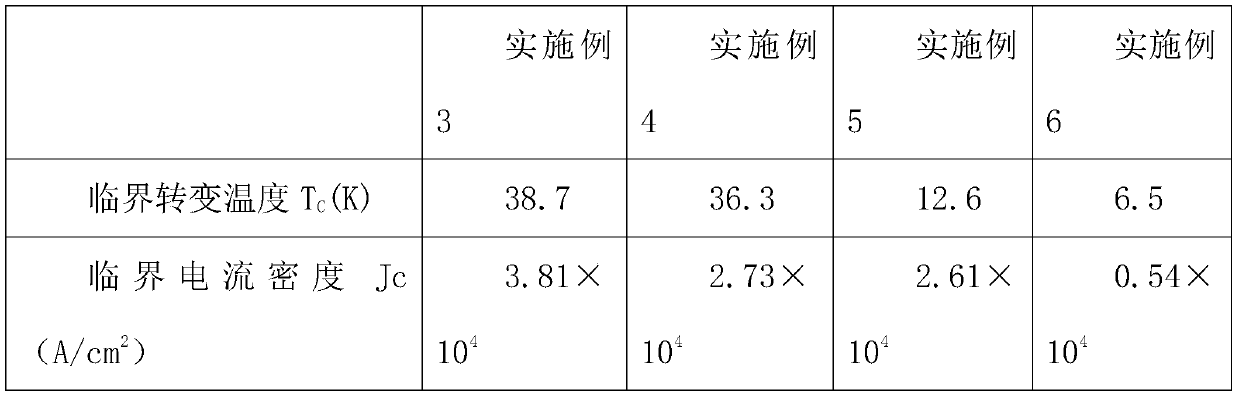

Embodiment 3

[0034] A specific preparation process of a superconducting material for nuclear magnetic resonance human imaging is as follows:

[0035] The first step, 1.11kg diyttrium trioxide and 2.39kg cupric oxide are dissolved in concentration respectively in the dilute nitric acid of 55%, configuration concentration is the yttrium nitrate solution of 1mol / L and the copper nitrate solution that concentration is 3mol / L, simultaneously Barium nitrate is added into water to be configured as a barium nitrate solution with a concentration of 2 mol / L;

[0036] In the second step, add the yttrium nitrate solution configured in the first step into the reaction vessel, raise the temperature to 60°C, then add 2.24 kg of diethylenetriamine dropwise to the yttrium nitrate solution, stir vigorously while adding, and dropwise completely After constant temperature reaction for 30min, yttrium sol was obtained;

[0037] In the third step, add the copper nitrate solution and barium nitrate solution conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com