Preparation method and application of a lanthanum-doped mesoporous carbon film

A mesoporous carbon, lanthanum-doped technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve harmful algal toxins, aquatic species death, aquatic plants and algae overgrowth and other issues, to achieve the effect of low cost, high separation efficiency, and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

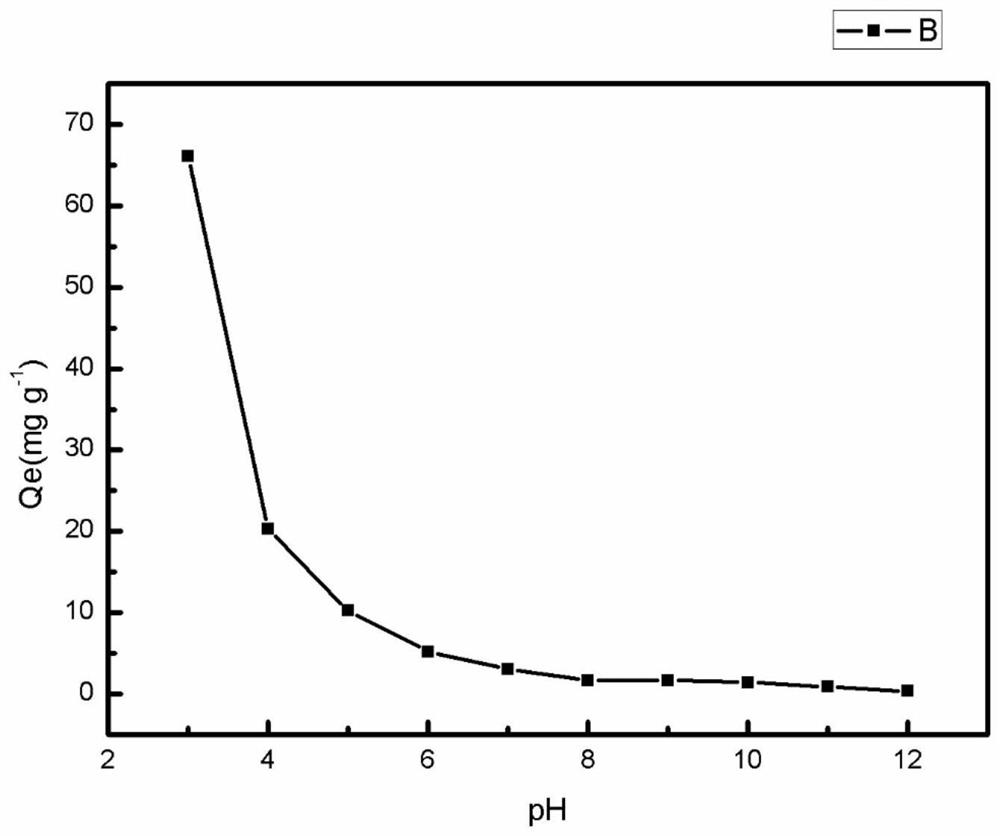

Examples

Embodiment 1

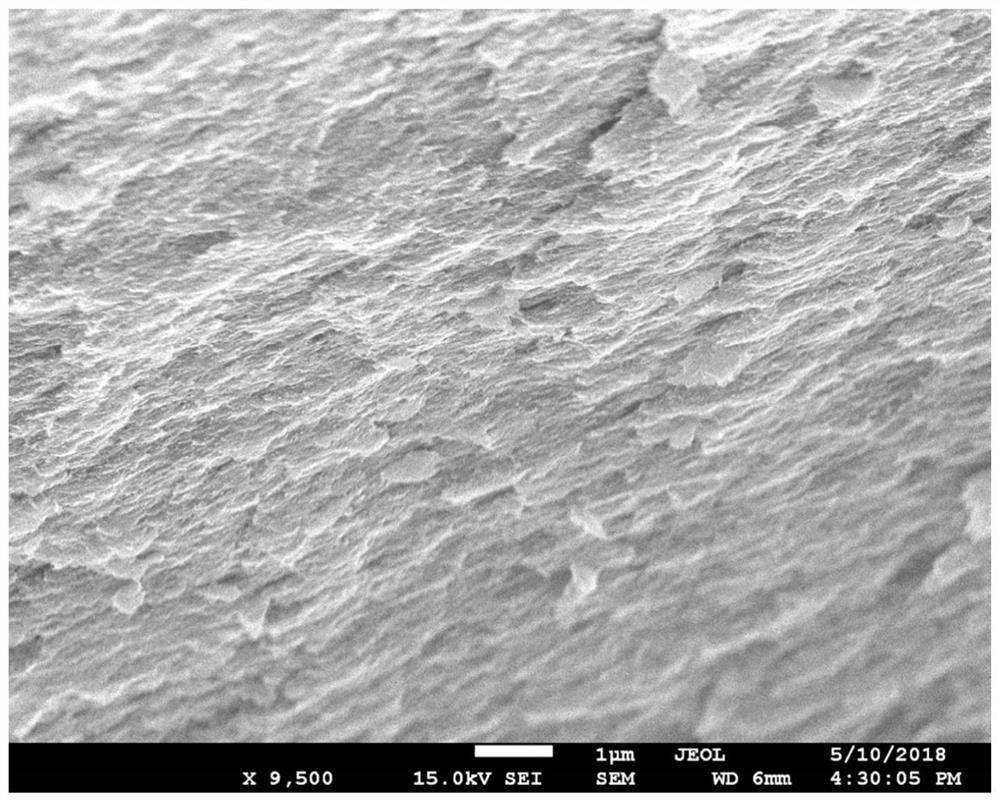

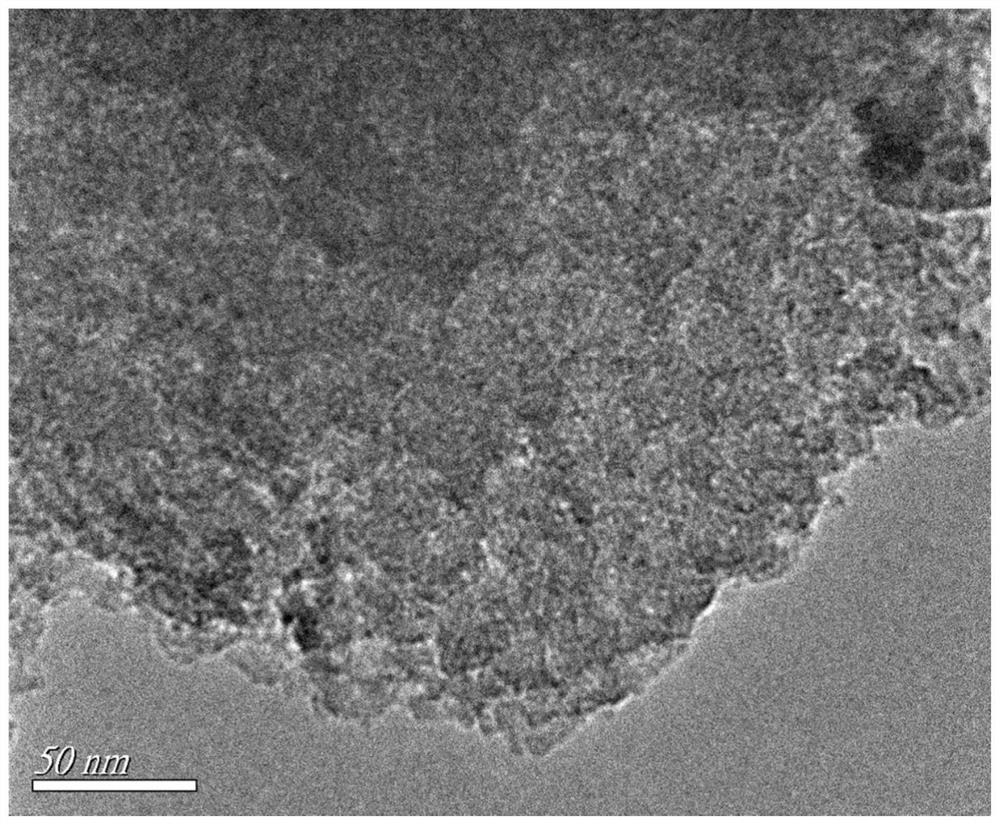

[0041] (1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 40%, then stir and react at 45°C for 2h, then transfer it to a beaker, dilute to 1000mL with distilled water, then let it stand overnight for stratification, pour Remove the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous, transfer the suspension to a dialysis membrane and dialyze for 2 to 4 days until the pH is about 2.4, then sonicate for 10 minutes, dilute to obtain nanocellulose crystals (NCC) for use;

[0042] (2) Pipette 10 mL of the NCC obtained in step (1), sonicate for 30 min until it becomes transparent, place it in a round bottom flask, add 500 μL of tetramethoxysilane (TMOS), then add 20 mg of nitric acid hexahydrate, at 25 °C Stir and react for 2 hours, pour into a watch glass and dry in a water bath at 25°C for 1 to 2 days;

[0043] (3) Put the composite film synthesized in step (2) in ...

Embodiment 2

[0057] (1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 50%, then stir and react at 45°C for 3h, then transfer it to a beaker, dilute to 1000mL with distilled water, then let it stand overnight and pour Remove the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous, transfer the suspension to a dialysis membrane and dialyze for 2 to 4 days until the pH is about 2.4, then sonicate for 10 minutes, dilute to obtain nanocellulose crystals (NCC) for use;

[0058] (2) Pipette 10 mL of NCC obtained in step (1), sonicate for 30 min until transparent, place in a round bottom flask, add 700 μL of tetramethoxysilane (TMOS), then add 15 mg of nitric acid hexahydrate, 25 ° C Stir and react for 2 hours, pour into a watch glass and dry in a water bath at 25°C for 1 to 2 days;

[0059] (3) Put the composite film synthesized in step (2) in a porcelain boat, and calcined at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com