Modified gypsum-based building board with thermal insulation performance and waterproof performance

A gypsum-based, construction technology, applied in the field of new functional materials, can solve the problems of poor air permeability, wear resistance and durability of coatings, poor water resistance of gypsum, limiting the application scope, and reducing the performance of gypsum boards, and achieves the reduction of water absorption, Hydrophobicity and physical and mechanical properties guarantee, the effect of mechanical properties improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

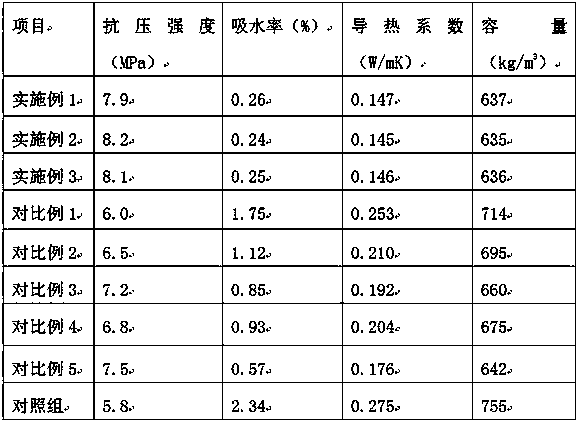

Examples

Embodiment 1

[0017] A modified gypsum-based building board with thermal insulation and water resistance, made of the following ingredients in parts by weight: 120 parts of gypsum powder, 4.5 parts of modified filler, 14 parts of plant foaming agent, aminopropyl triethoxy 1.0 part of silane, 0.5 part of sodium trimetaphosphate, 0.1 part of potassium sulfate, 1.5 parts of calcium carbonate, 7.0 parts of water-based epoxy resin emulsion, 16 parts of water, the preparation method of the modified filler comprises the following steps:

[0018] (1) Mix 15 grams of zeolite powder and 3.9 grams of basalt fiber, place in a muffle furnace, raise the temperature to 550°C, keep the temperature for calcination for 2.0 hours, cool to room temperature naturally with the furnace, grind to pass through a 180 mesh sieve, and mix with sodium borate Mix according to the mass ratio of 1.8:0.3, and add it to 50 ml of hot water at 60°C, stir to obtain the mixture, add 150 ml of sodium hydroxide solution to the bea...

Embodiment 2

[0026] A modified gypsum-based building board with thermal insulation and water resistance, made of the following components in parts by weight: 122 parts of gypsum powder, 4.8 parts of modified filler, 15 parts of plant foaming agent, aminopropyl triethoxy 1.1 parts of silane, 0.55 parts of sodium trimetaphosphate, 0.15 parts of potassium sulfate, 1.6 parts of calcium carbonate, 7.5 parts of water-based epoxy resin emulsion, 18 parts of water, the preparation method of the modified filler comprises the following steps:

[0027] (1) Weigh 15.5 grams of zeolite powder and 3.95 grams of basalt fiber, put them in a muffle furnace, raise the temperature to 565 ° C, keep the temperature for calcination for 2.2 hours, cool to room temperature naturally with the furnace, grind to pass through a 190-mesh sieve, and mix with sodium borate Mix according to the mass ratio of 1.9:0.35, and add to 55 ml of hot water at 62°C, stir to obtain the mixture, add 155 ml of sodium hydroxide solutio...

Embodiment 3

[0035] A modified gypsum-based building board with thermal insulation and water resistance, which is made of the following components in parts by weight: 125 parts of gypsum powder, 5.0 parts of modified filler, 16 parts of plant foaming agent, aminopropyl triethoxy 1.2 parts of silane, 0.6 part of sodium trimetaphosphate, 0.2 part of potassium sulfate, 1.8 parts of calcium carbonate, 8.0 parts of water-based epoxy resin emulsion, 20 parts of water, the preparation method of the modified filler comprises the following steps:

[0036] (1) Weigh 16 grams of zeolite powder and 4.0 grams of basalt fiber, mix them in a muffle furnace, raise the temperature to 580 ° C, keep the heat for calcination for 2.5 hours, cool to room temperature naturally with the furnace, grind to pass through a 200-mesh sieve, and mix with sodium borate Mix according to the mass ratio of 2.0:0.4, and add it to 60 ml of hot water at 65°C, stir to obtain the mixture, add 160 ml of sodium hydroxide solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com