A method for reducing the ohmic contact resistance of a wide band gap semiconductor device

A wide bandgap semiconductor and ohmic contact electrode technology, which is applied in the field of reducing the ohmic contact resistance of III-V wide bandgap semiconductor devices, can solve problems greater than 0.5Ω, etc., to reduce ohmic contact resistance, increase ohmic contact area, enhance The effect of device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

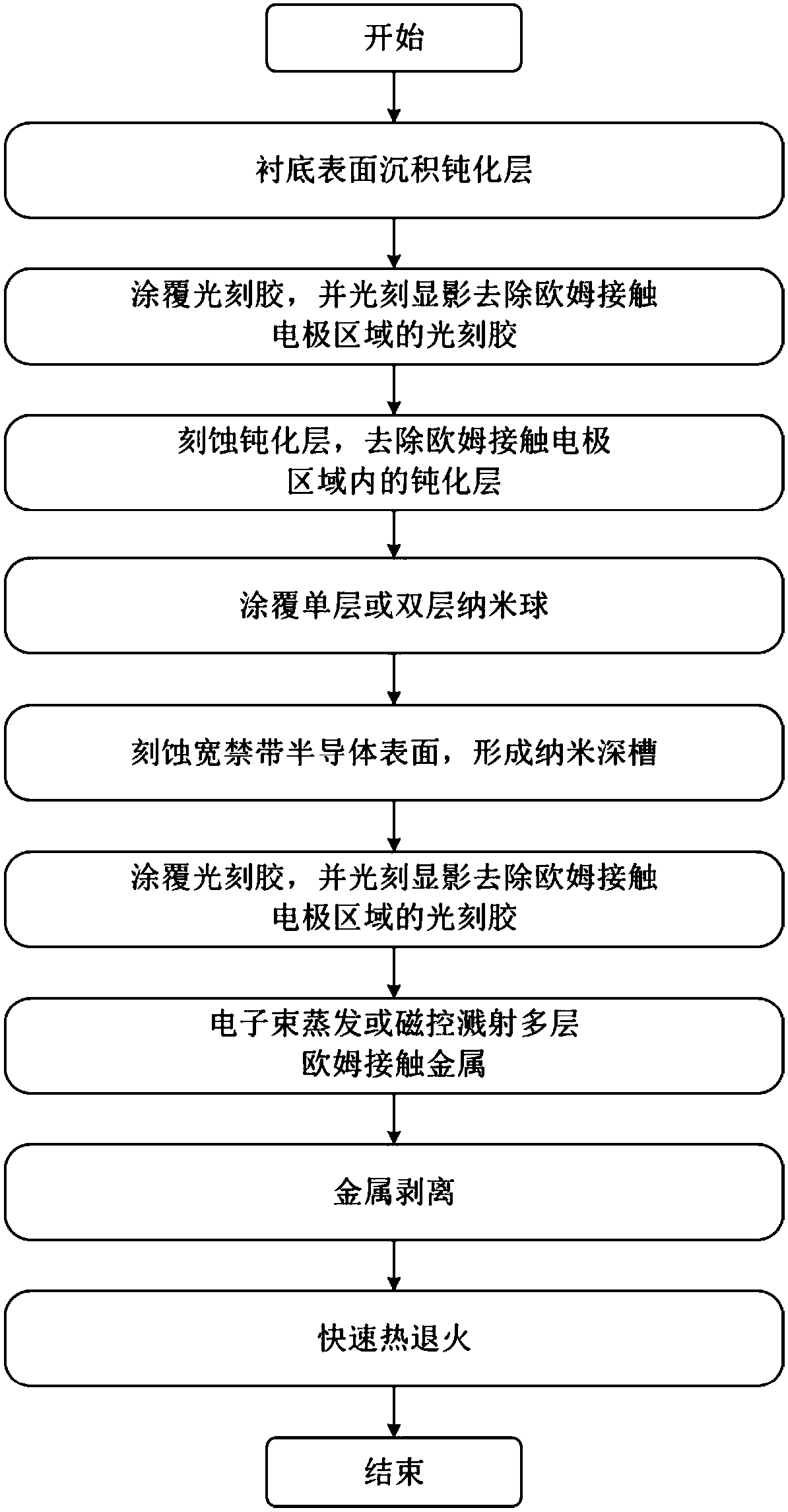

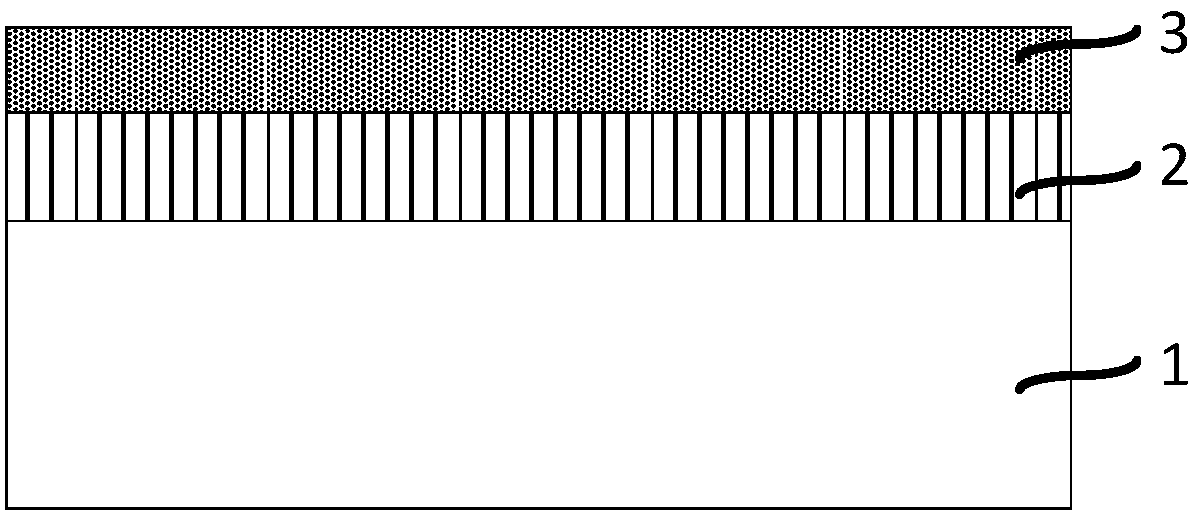

[0057] Step 1, depositing a passivation layer, the material is Si 3 N 4

[0058] Deposit a layer of 100nm Si on the surface of wide band gap semiconductor material by PECVD (plasma enhanced chemical vapor deposition) 3 N 4 passivation layer;

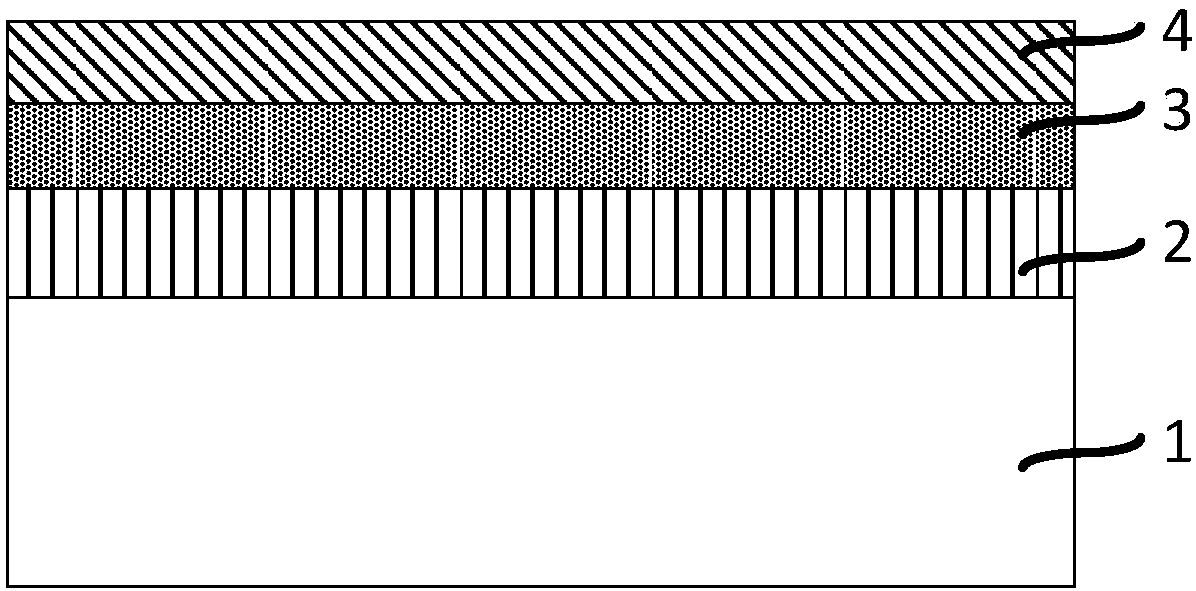

[0059] Step 2, apply photoresist, and photolithographic development to remove the photoresist in the ohmic contact electrode area

[0060] Coat photoresist AZ5214E on the passivation layer deposited in step 1, pre-bake at 90°C for 90s, expose to ultraviolet light for 6s, develop with 2.38% tetramethylammonium hydroxide solution for 45s, and remove the photoresist in the ohmic contact electrode area glue to form a photoresist window, and post-bake at 110°C for 30s;

[0061] Step 3, etch the passivation layer, remove the passivation layer in the ohmic contact electrode area, and remove the photoresist

[0062] The passivation layer is etched by RIE (Reactive Ion Etching), and the working gas is CF 4 with O 2 , RF power 100W, time...

Embodiment 2

[0076] Step 1, depositing a passivation layer, the material is SiO 2

[0077] Using ICPCVD (inductively coupled plasma chemical vapor deposition) to deposit a layer of 50nm SiO on the surface of wide bandgap semiconductor materials 2 passivation layer;

[0078] Step 2, apply photoresist, and photolithographic development to remove the photoresist in the ohmic contact electrode area

[0079] Coat photoresist AZ5214E on the passivation layer deposited in step 1, pre-bake at 90°C for 90s, expose to ultraviolet light for 6s, develop with 2.38% tetramethylammonium hydroxide solution for 45s, and remove the photoresist in the ohmic contact electrode area glue to form a photoresist window, and post-bake at 110°C for 30s;

[0080] Step 3, etch the passivation layer, remove the passivation layer in the ohmic contact electrode area, and remove the photoresist

[0081] ICPRIE (Inductively Coupled Plasma Etching) is used to etch the passivation layer, and the working gas is SF 6 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com