A copper nitride modified lithium battery material, a preparation method and an application thereof

A technology of lithium battery materials and nitrides, which is applied in lithium batteries, secondary batteries, battery electrodes, etc., can solve the problems of not being widely commercialized, difficult to apply, and potential safety hazards of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

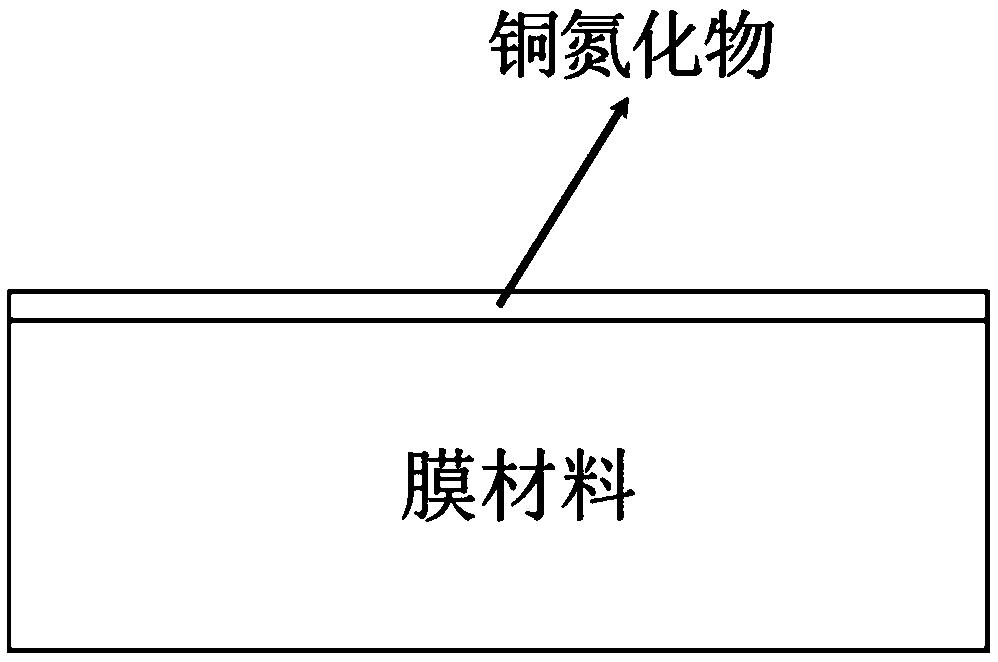

[0071] In this embodiment, copper nitride is used to modify the metal lithium negative electrode.

[0072] 1. First, pre-treat the metal lithium strip, scrape off the passivation layer on the surface of the metal lithium strip with a thickness of 120 μm with a blade / scraper, and then polish it with sandpaper or a polishing rod. Then through the glove box rolling device, the polished lithium strip and the punched copper foil are rolled together. During the rolling process, a PE film with a thickness of 180 μm needs to be covered on the front and back of the lithium strip to prevent adhesion to the roller. The rolling thickness is set at 400 μm, so that a relatively flat and uniform lithium strip can be obtained. Pass the obtained lithium strip through the punching equipment in the glove box and punch it into button battery negative plate.

[0073] 2. Fix the obtained negative plate in the sample drag of magnetron sputtering, transfer it to the transition chamber of the magne...

Embodiment 2

[0080] In this embodiment, copper nitride is used to modify the metal lithium negative electrode.

[0081] 1. First pre-treat the metal lithium strip, scrape off the passivation layer on the surface of the metal lithium strip with a thickness of 120 μm with a blade / scraper, and then polish it with sandpaper or a polishing rod. Then cover the PE film with a thickness of 180 μm on the front and back of the metal lithium strip, and perform cold pressing to obtain a relatively flat and uniform lithium strip. Pass the obtained lithium strip through the punching equipment in the glove box and punch it into button battery negative plate.

[0082] 2. Fix the obtained negative plate in the sample drag of magnetron sputtering, transfer it to the transition chamber of the magnetron sputtering equipment through the nitrogen atmosphere protection device, and then transfer it to the main chamber for copper nitride sputtering coating, target Select metal Cu target. The total pressure of ...

Embodiment 3

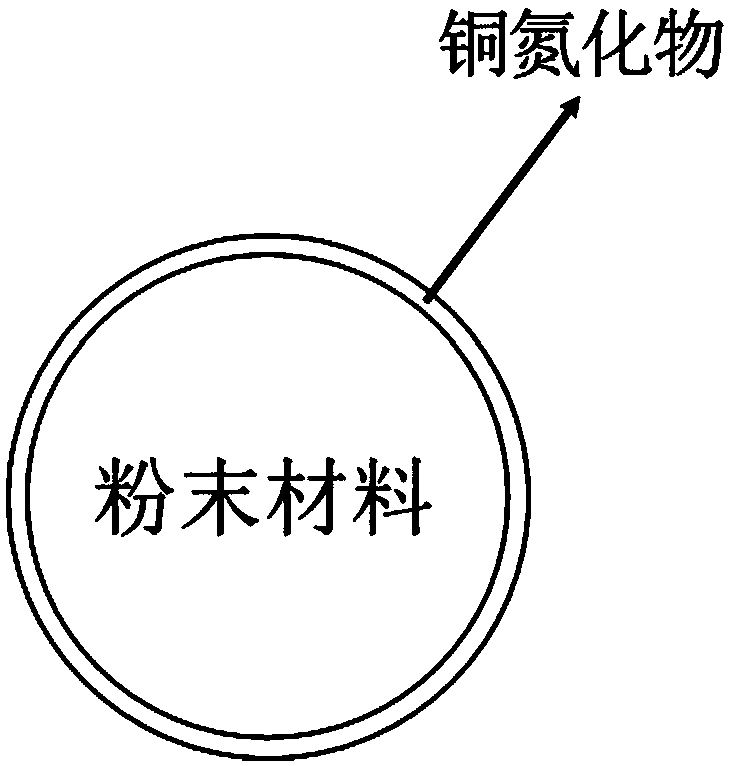

[0089] In this embodiment, copper nitride is used to modify the Cu current collector.

[0090] 1. First, pre-treat the surface of the Cu foil. Flatten the copper foil with a thickness of 12 μm on the surface of a large flat substrate, scrub it repeatedly with alcohol and deionized water, and bake it in a vacuum oven at 110°C for 6 hours. A Cu foil with a clean surface was obtained. Then, the obtained Cu foil is punched into button battery negative plate.

[0091] 2. Fix the obtained negative plate in the sample drag of magnetron sputtering, transfer it to the transition chamber of the magnetron sputtering equipment through the nitrogen atmosphere protection device, and then transfer it to the main chamber for copper nitride sputtering coating, target Select metal Cu target. The total pressure of the magnetron sputtering coating is 1Pa, and the reaction gas is N 2 (50%), the carrier gas is Ar (50%), the sputtering power is 40W, and the sputtering time is 10min.

[0092] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com