Insulating environment-friendly brick and preparation method thereof

A brick and environmental protection technology, applied in the field of bricks, can solve the problems of low mechanical strength and poor thermal insulation performance of bricks, and achieve the effects of improving anticorrosion performance, improving thermal insulation performance, and improving specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

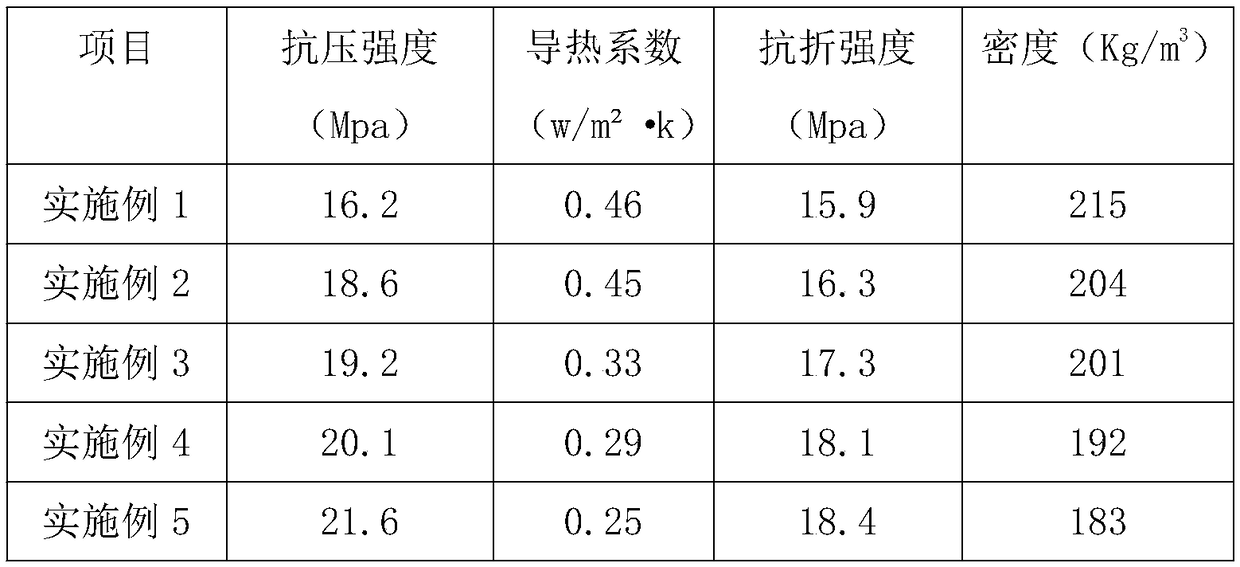

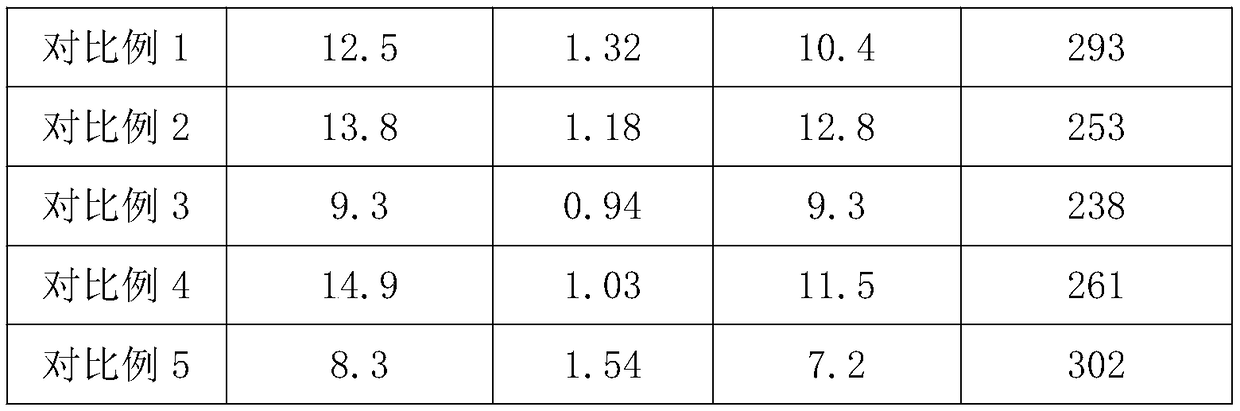

Examples

Embodiment 1

[0029] This embodiment relates to a thermal insulation and environmental protection brick, comprising the following raw materials in parts by weight, 50 parts of slag portland cement, 30 parts of waste cement brick powder, 20 parts of coal gangue, 15 parts of bonding agent, diisopropyl peroxide 6 parts of benzene, 12 parts of carbonized crop straw powder, 10 parts of magnesium oxide, 8 parts of barium stearate, 4 parts of lignin, and 2 parts of triethanolamine.

[0030] Wherein, the preparation method of the waste cement brick powder is as follows: crush the waste cement brick into a particle size of 20 mesh, calcinate it at 400°C for 30 minutes, then crush it to a particle size of 100 mesh, and then add stannous oxide to surface processing to obtain the waste cement brick powder.

[0031] Wherein, the preparation method of the carbonized crop straw powder is as follows: washing, drying and pulverizing the crop straw, passing through a 30-mesh sieve, carbonizing the straw at a...

Embodiment 2

[0043] This embodiment relates to a thermal insulation and environmental protection brick, including the following raw materials in parts by weight, 60 parts of slag Portland cement, 40 parts of waste cement brick powder, 30 parts of coal gangue, 30 parts of bonding agent, diisopropyl peroxide 12 parts of benzene, 18 parts of carbonized crop straw powder, 14 parts of magnesium oxide, 14 parts of barium stearate, 8 parts of lignin, and 5 parts of triethanolamine.

[0044] Wherein, the preparation method of the waste cement brick powder is as follows: crush the waste cement brick into a particle size of 50 mesh, calcinate it at 600°C for 60 minutes, then crush it to a particle size of 200 mesh, and then add stannous oxide for surface processing to obtain the waste cement brick powder.

[0045] Wherein, the preparation method of the carbonized crop straw powder is as follows: washing, drying and crushing the crop straw, passing through a 60-mesh sieve, carbonizing the straw at a ...

Embodiment 3

[0057] This embodiment relates to a thermal insulation and environmental protection brick, comprising the following raw materials in parts by weight, 52 parts of slag portland cement, 32 parts of waste cement brick powder, 22 parts of coal gangue, 17 parts of bonding agent, diisopropyl peroxide 8 parts of benzene, 14 parts of carbonized crop straw powder, 11 parts of magnesium oxide, 10 parts of barium stearate, 5 parts of lignin, and 3 parts of triethanolamine.

[0058] Wherein, the preparation method of the waste cement brick powder is as follows: crush the waste cement brick into a particle size of 20 mesh, calcinate it at 400°C for 30 minutes, then crush it to a particle size of 100 mesh, and then add stannous oxide to surface processing to obtain the waste cement brick powder.

[0059] Wherein, the preparation method of the carbonized crop straw powder is as follows: washing, drying and pulverizing the crop straw, passing through a 30-mesh sieve, carbonizing the straw at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com