Safe and environment-friendly aromatic amine production system and process

A production system, safe and environmentally friendly technology, applied in the field of phenylenediamine and aniline production, can solve the problems of harsh nitrification conditions, large amount of desolventization, large consumption of washing water and alkali, saving investment and operating costs, and reducing nitrification. The amount of materials and the effect of saving running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

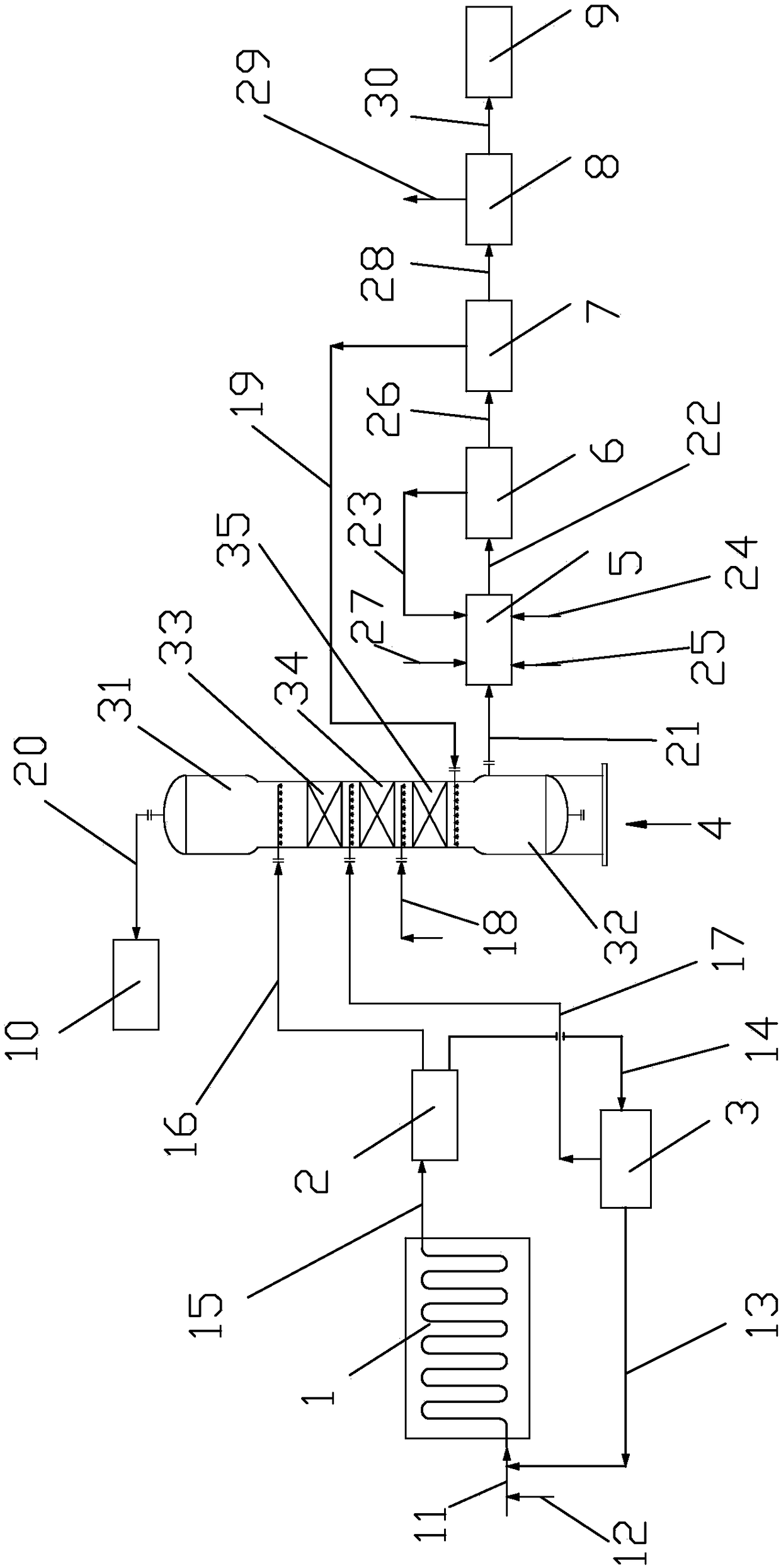

[0038] Such as figure 1 As shown, it is a safe and environment-friendly aromatic amine production system and process of the present invention, including a nitration system, a washing system, a hydrogenation desolventization system, and a dehydration deaniline system. The nitration system includes a microchannel nitrator 1 and an acid separator 2 And vacuum concentration system 3, the outlet of microchannel nitrator 1 is connected with the inlet of acid separator 2, the outlet of acid separator 2 is connected with the inlet of vacuum concentration system 3, and the washing system includes washing tower 4 and sewage treatment system 10, washing The inlet of the tower 4 is connected with the vacuum concentration system 3 and the acid separator 2 respectively, the outlet of the washing tower 4 is connected with the sewage treatment system 10, and the hydrogenation and desolventization system includes a hydrogenation system 5 and a desolventization tower 6, and the hydrogenation sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com