Preparation method of chromium picolinate

A technology of chromium picolinate and picolinate, which is applied in the field of chromium picolinate, can solve the problems of high melting point, ammonia-containing waste pollution, long reaction time, etc., and achieve the effects of shortening the process flow, high product yield and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

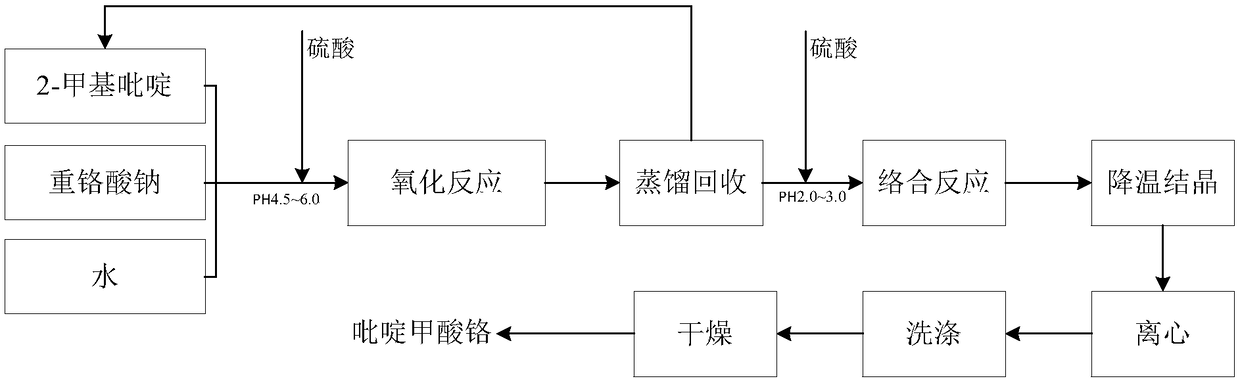

[0020] Such as figure 1 Shown, the preparation method of the chromium picolinate provided by the present embodiment comprises the steps:

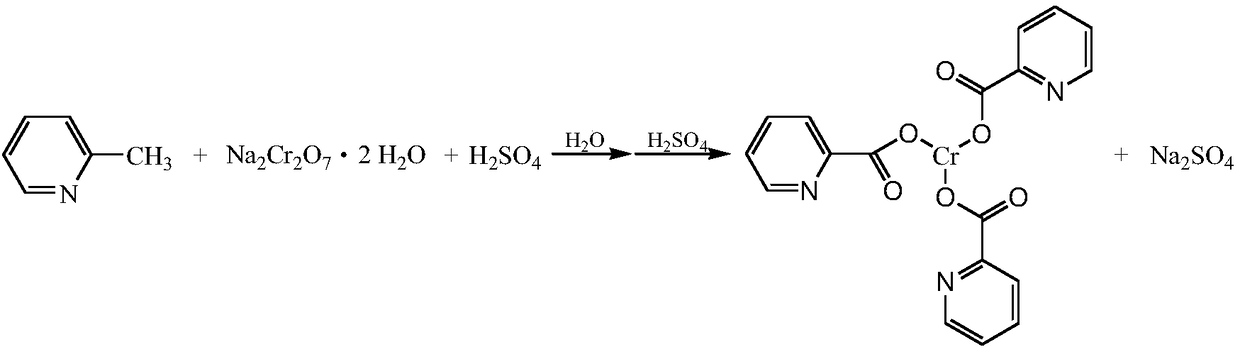

[0021] (1) Put 80kg of 2-picoline, 246kg of sodium dichromate and 400kg of water into the reactor, add sulfuric acid to adjust the pH value to 4.5-5.0, and then heat to make the temperature in the reactor 200-210 ℃, pressure 2.5 ~ 3.2MPa, heat preservation and pressure oxidation reaction for 1h;

[0022] (2) The temperature in the reaction kettle is reduced to 85-90° C., distilled under reduced pressure, and the distillate is a 2-picoline aqueous solution, which can be used as a raw material for the next production;

[0023] (3) Add sulfuric acid to the reaction kettle that has been distilled under reduced pressure, adjust the pH value to 2.0-2.5, and keep the temperature at 85-90°C, perform complexation reaction under normal pressure for 5h, and then lower the temperature to 20-30°C Crystallize, finally centrifuge, wash with 50kg of wate...

Embodiment 2

[0025] The preparation method of the chromium picolinate provided by the present embodiment may further comprise the steps:

[0026] (1) Put 100kg of 2-picoline, 246kg of potassium dichromate and 400kg of water into the reactor, add hydrochloric acid to adjust the pH value to 5.0-5.5, and then heat to make the temperature in the reactor 210-230 ℃, pressure 2.2 ~ 3.2MPa, heat preservation and pressure oxidation reaction for 10h;

[0027] (2) The temperature in the reaction kettle is reduced to 85-90° C., distilled under reduced pressure, and the distillate is a 2-picoline aqueous solution, which can be used as a raw material for the next production;

[0028] (3) Add hydrochloric acid to the reaction kettle that has been distilled under reduced pressure, adjust the pH value to 2.5-3.0, and keep the temperature at 85-90°C, perform complexation reaction under normal pressure for 1h, and then lower the temperature to 20-30°C Crystallize, finally centrifuge, wash with 50kg of water...

Embodiment 3

[0030] The preparation method of the chromium picolinate provided by the present embodiment may further comprise the steps:

[0031] (1) Put 100kg of 2-picoline, 246kg of ammonium dichromate and 400kg of water into the reactor, add phosphoric acid to adjust the pH value to 5.0-5.5, and then heat to make the temperature in the reactor 230-240 ℃, pressure 3.2 ~ 3.5MPa, heat preservation and pressure oxidation reaction for 6 hours;

[0032] (2) The temperature in the reaction kettle is reduced to 85-90° C., distilled under reduced pressure, and the distillate is a 2-picoline aqueous solution, which can be used as a raw material for the next production;

[0033] (3) Add phosphoric acid to the reaction kettle that has been distilled under reduced pressure, adjust the pH value to 2.0-3.0, and keep the temperature at 85-90°C, perform complexation reaction under normal pressure for 1h, and then lower the temperature to 20-30°C Crystallize, finally centrifuge, wash with 50kg of water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com